A wear-resistant and anti-corrosion PVC plastic pipe set and preparation method thereof

A technology of plastic pipe fittings and plastic pipes, applied in the direction of pipe elements, pipes/pipe joints/pipe fittings, siphon pipes, etc., can solve the problem of low heat resistance and aging resistance of PVC, material omission at the joint of plastic pipe kits, and aging and brittleness of pipe fittings cracking and other problems, to achieve high anti-oxidation performance, to achieve the effect of anti-oxidation performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

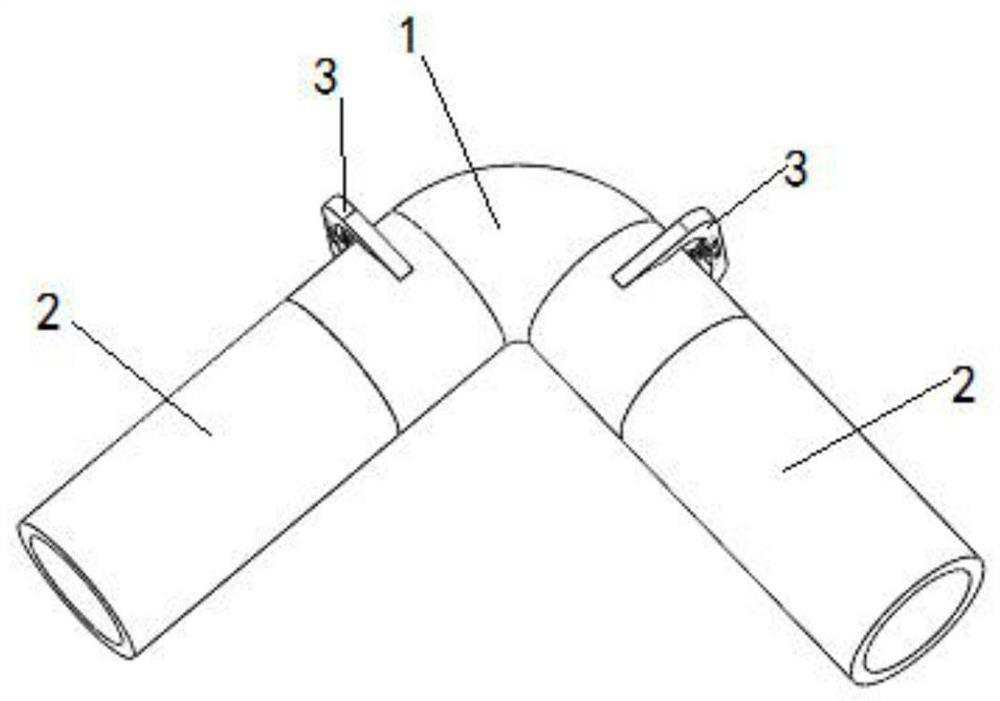

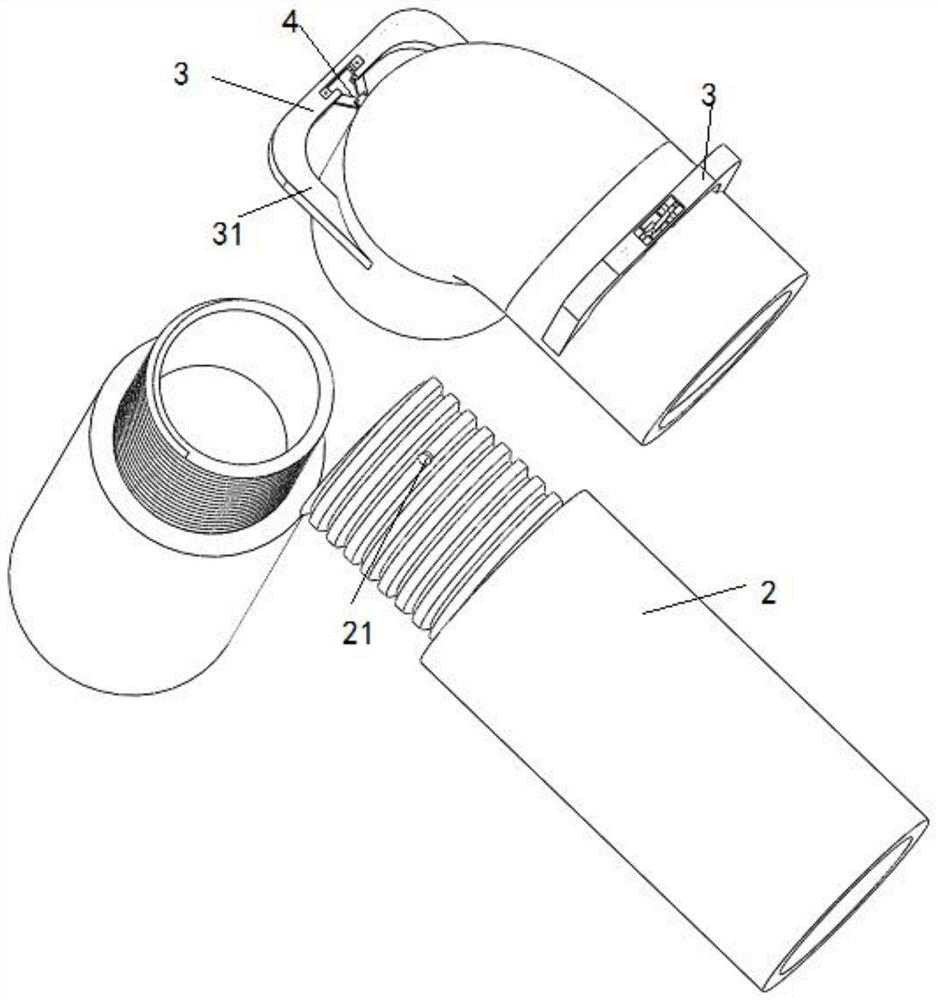

[0035] A wear-resistant and anti-corrosion PVC plastic pipe kit such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a pipe joint 1 and a plastic pipe 2 connected and fixed through the pipe joint 1;

[0036] The pipe fitting 1 and the plastic pipe fitting 2 are fixed by screw connection;

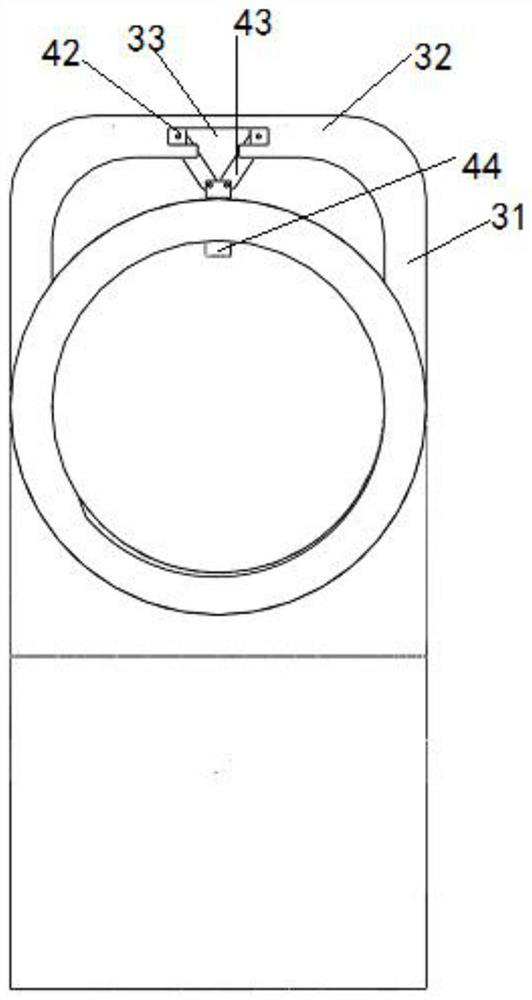

[0037] The outer surface of the side wall of each pipe fitting 1 is close to the connection with the plastic pipe fitting 2. A limit fixing table 3 is provided, and an elastic limiter seat 4 is installed in the limiter fixation table 3. Limit and fix between the plastic pipe fitting 2;

[0038] The inner surface of the side wall of the joint end of the pipe joint 1 is provided with internal threads, and the inner surface of the side wall of the joint end is provided with a limit hole 11 extending to the inner cavity of the pipe fitting. At the same time, the outer surface of the side wall of one end of the plastic pipe fitting 2 is provided with an ex...

Embodiment 2

[0046] The specific preparation process of the unsaturated antioxidant is as follows: Add 12.2g of salicylaldehyde into 100mL of ether and stir to dissolve, then add 7.1g of acrylamide to it, heat up to 60-70°C and stir for 8-10h, then carry out vacuum distillation , to obtain unsaturated antioxidants.

Embodiment 3

[0048] A wear-resistant and anti-corrosion PVC plastic pipe kit, in which the pipe joints and plastic pipe fittings are prepared from high-temperature-resistant and anti-corrosion plastic masterbatches, wherein the specific preparation process of the high-temperature-resistant and anti-corrosion plastic masterbatches is as follows:

[0049] In the first step, 8.5kg of PVC resin and 100g of allyl mercaptan are simultaneously added to a screw extruder for melt extrusion to obtain a modified PVC material;

[0050] In the second step, the modified PVC material prepared in the first step, the unsaturated antioxidant prepared in 0.4kg embodiment 2, 0.2kg allyltrimethylsilane, 0.5kg azobisisobutyronitrile and 0.2kg The dispersant is added to the reaction vessel at the same time, the temperature is raised to 140-150°C, stirred and mixed for 2-3 hours, then the material is cooled and discharged, and the material is put into a single-screw extruder for melt extrusion and granulation to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com