Needle type quantitative grease filling gun

A butter filling and needle-type technology, applied to engine components, engine lubrication, pressure lubricants, etc., can solve the problems of easily polluting the cloth surface, difficult to control, and less oiling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

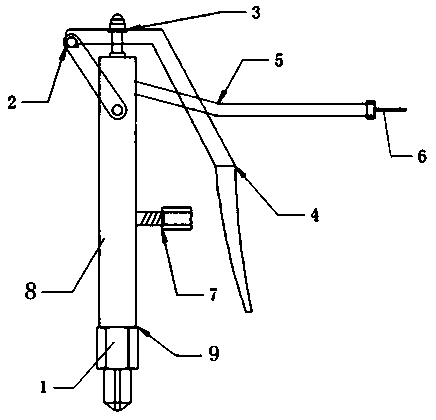

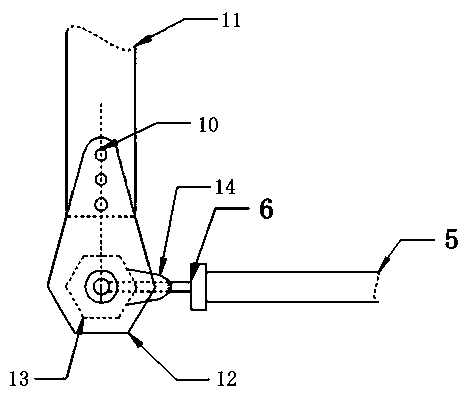

[0012] Such as figure 1 As shown, the present invention comprises a gun body 8, a pressure handle 4, a refueling pipe 5, and a needle type refueling nozzle 6. One end of the gun body 8 is connected with a butter oil delivery pipe through a connecting nut 1, and the butter oil delivery pipe is connected with a butter barrel and compressed air. The other end of the body 8 is provided with a pressure bolt 3, and the pressure handle 4 contacts the pressure bolt 3 and is connected with the gun body 8 through the connecting pin 2. On the gun body 8, an end near the pressure bolt 3 is provided with a refueling pipe 5, and the end of the refueling pipe 5 The top end is threadedly connected with a needle-type oil nozzle 6; the gun body 8 is also provided with a limit screw 7, and when the pressure handle 4 is pressed down, the limit screw 7 controls the stroke of the pressure handle 4.

[0013] The stroke of the limit screw 7 can be adjusted.

[0014] The conventional caliber of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com