Grating displacement sensor and automatic detection equipment

A grating displacement and sensor technology, applied in the field of measuring instruments, can solve the problems of poor quality of Moiré fringes, unusability, and reduced precision of grating displacement sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

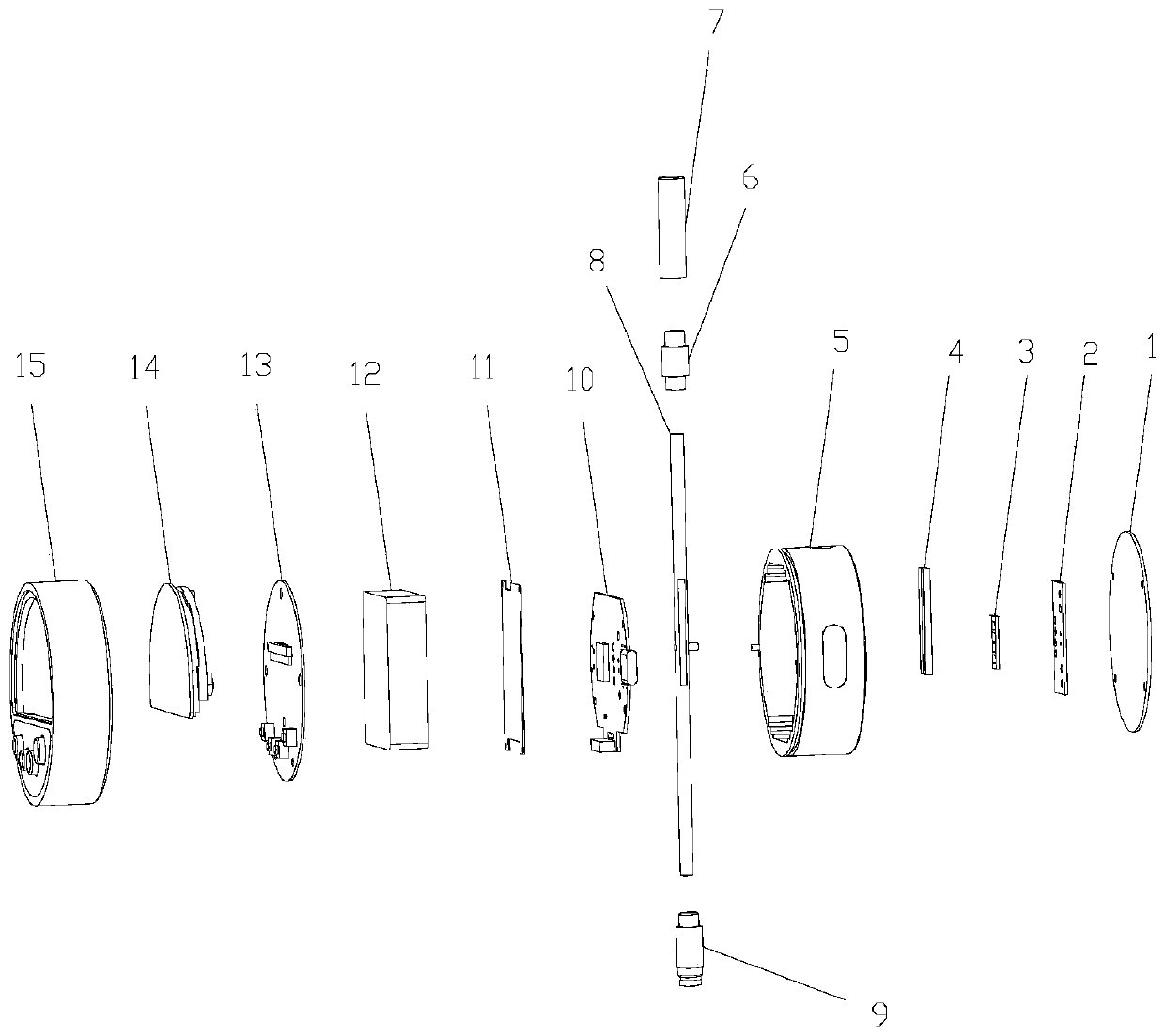

[0031] figure 1 Exploded view of the grating displacement sensor provided by Embodiment 1 of the present invention.

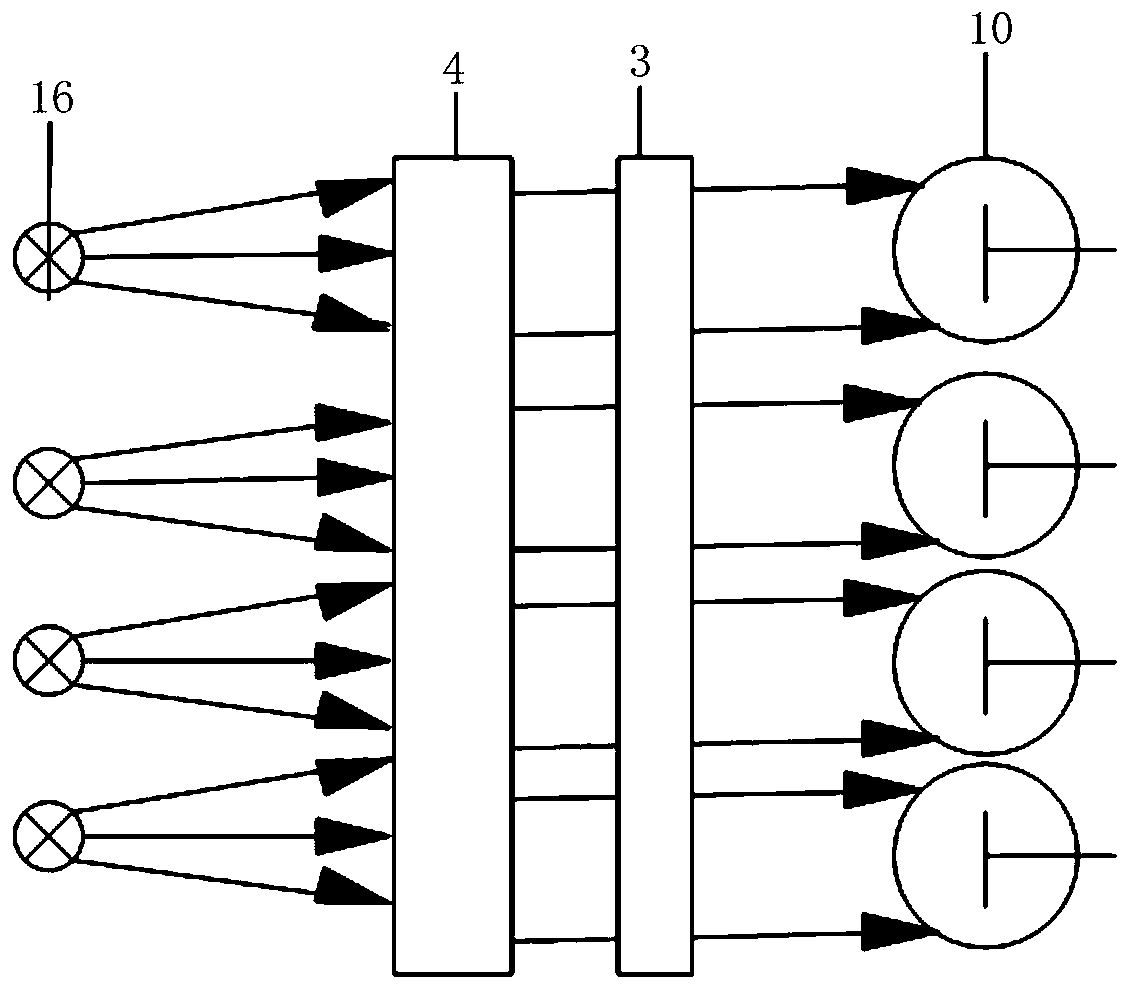

[0032] refer to figure 1 , the grating displacement sensor includes a cavity, and the cavity is provided with an infrared emitting circuit board 2, a plurality of infrared light emitting diodes, a scale grating 4, an indicating grating 3, an infrared photoelectric receiver 10, an infrared receiving circuit and a processing module 13; a plurality of infrared light emitting diodes Diodes are evenly arranged on the infrared emitting circuit board 2, and a plurality of infrared light emitting diodes are arranged above the scale grating 4, parallel to the surface of the scale grating 4; the scale grating 4 is fixed on the grating table, and parallel to the surface of the indicator grating 3 ; The indicator grating 3 is fixed above the infrared photoelectric receiver 10;

[0033] Infrared light-emitting diodes for emitting infrared point light sources;

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com