Pressure measuring device for preventing probe from icing through rotary rake

A technology of pressure measuring device and rotary rake, which is applied in the direction of measuring device, machine/structural component test, engine test, etc., which can solve the problems of increasing the working time of relevant personnel, reducing test efficiency, and occupying test time, etc., so as to avoid data The effect of collecting errors, improving test efficiency, and avoiding delays in test progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

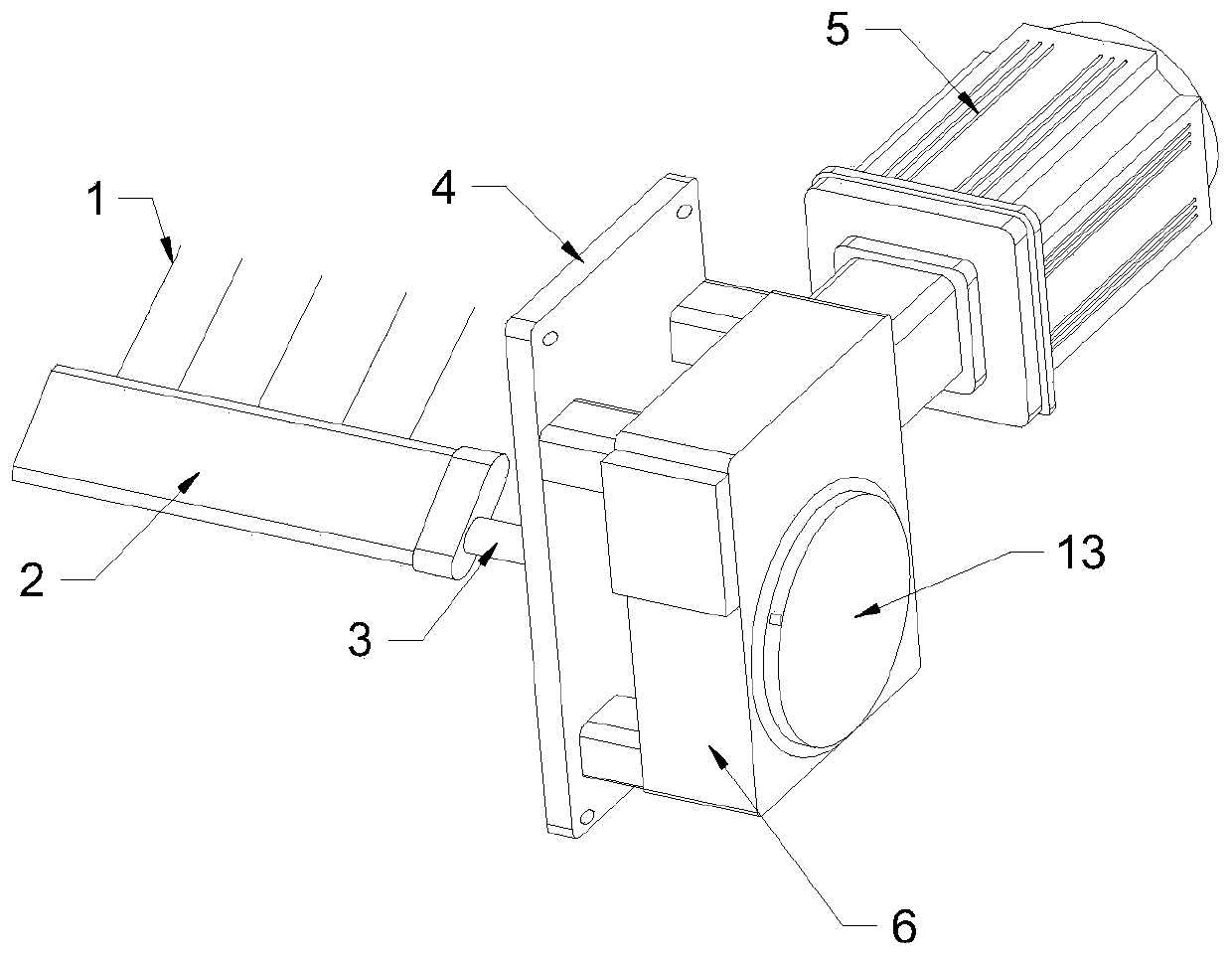

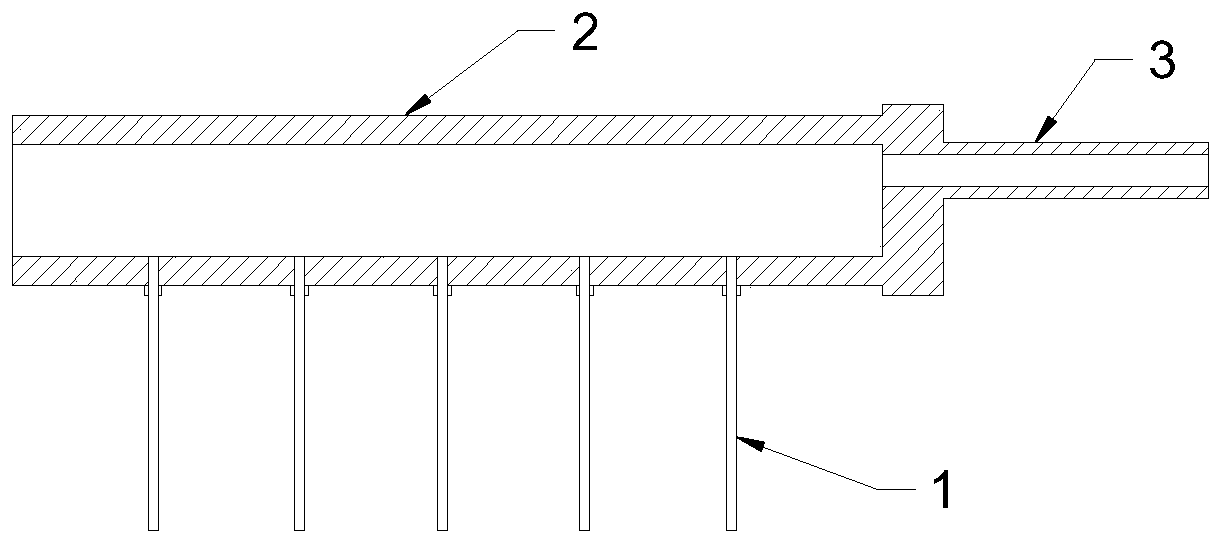

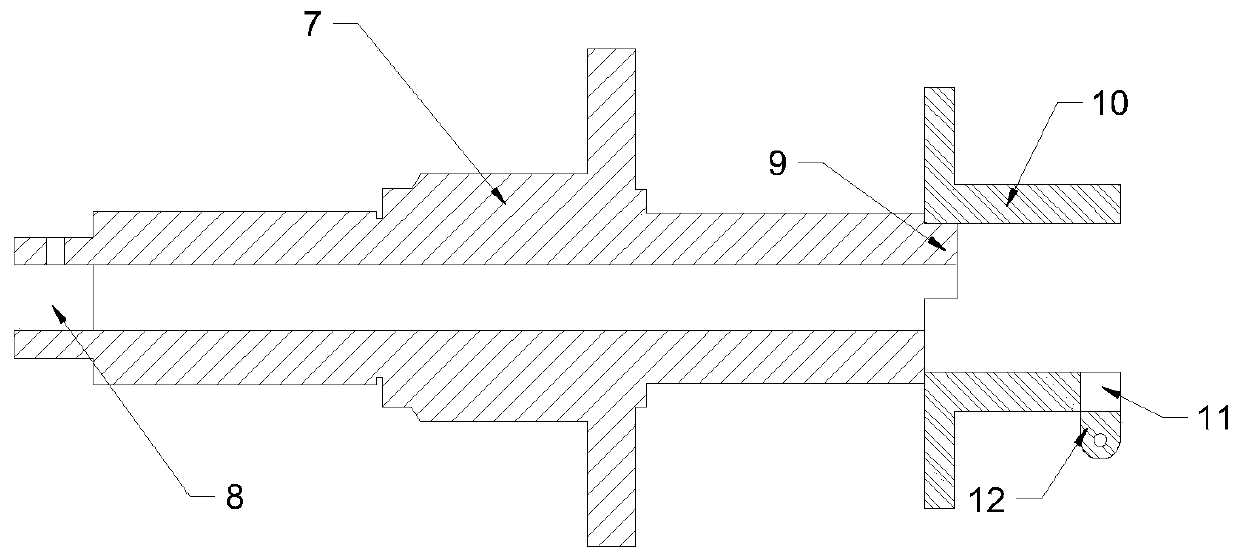

[0028] see figure 1 and figure 2 , a pressure measurement device that prevents the probe from freezing by rotating the rake, including a pressure measurement rake 2 with a plurality of pressure measurement probes 1 arranged in the air inlet, the pressure measurement rake 2 is a hollow paddle with a hollow shaft 3 The pressure measurement probe 1 is installed on the same side of the pressure measurement rake 2, and the pressure measurement probe 1 is parallel to the paddle-shaped surface of the pressure measurement rake 2, and the hollow shaft 3 is arranged on the pressure measurement rake 2 along the length direction of the pressure measurement rake 2 At one end, the hollow structure of the pressure measuring rake 2 communicates with the cavity of the hollow shaft 3; it also includes a connecting plate 4 installed on the outer surface of the air inlet, and a driving positioning device for driving the hollow shaft 3 to rotate and position is fixed on the connecting plate 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com