Production process control system for plant extraction

A technology for production process control and plant extraction, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as concentration difficulties and lack of sensor detection methods, achieve good extraction quality, realize precise control, and realize real-time Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is further described in conjunction with the following examples.

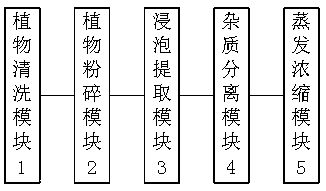

[0013] see figure 1 , a production process control system for plant extraction in this embodiment, comprising a plant cleaning module 1, a plant crushing module 2, a soaking extraction module 3, an impurity separation module 4 and an evaporation concentration module 5, the plant cleaning module 1 is used When the plants to be extracted are cleaned, the plant pulverization module 2 is used to pulverize the cleaned plants, and the soaking extraction module 3 is used to extract the active ingredients from the pulverized plants to obtain the extract containing the active ingredients. The impurity separation module 4 is used to remove impurities in the extraction solution, and the evaporation concentration module 5 is used to further evaporate the extraction solution obtained by soaking the extraction module so that the concentration of the extraction solution reaches a preset concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com