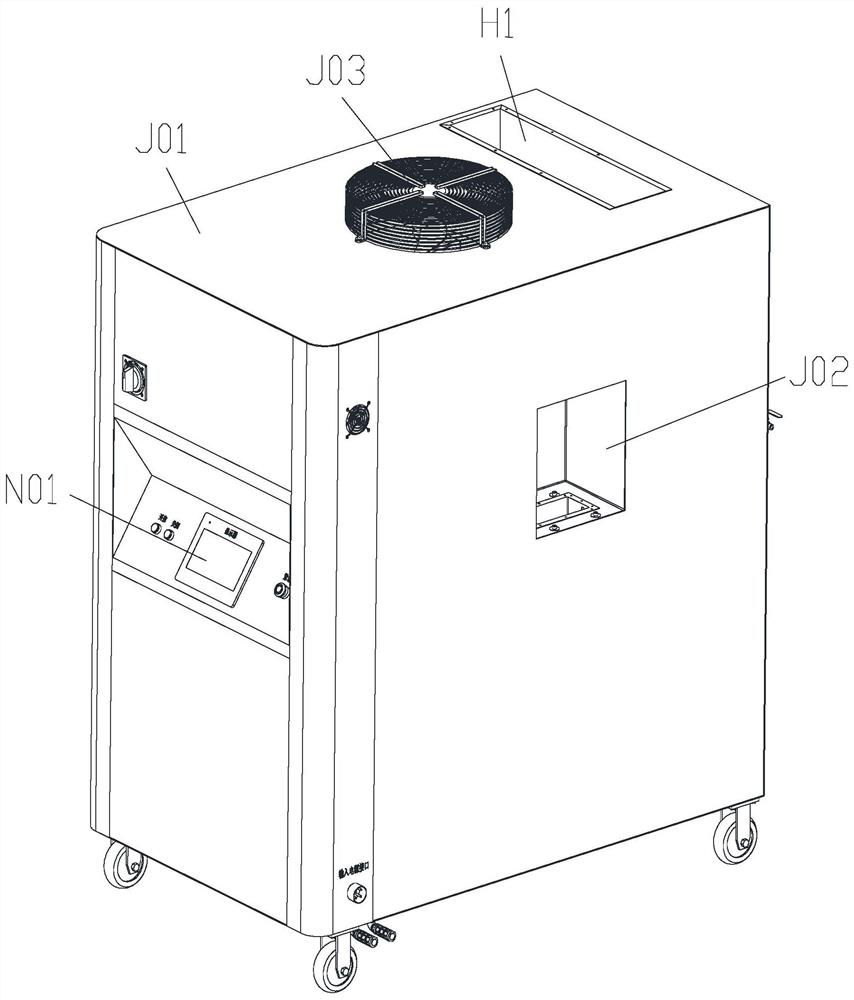

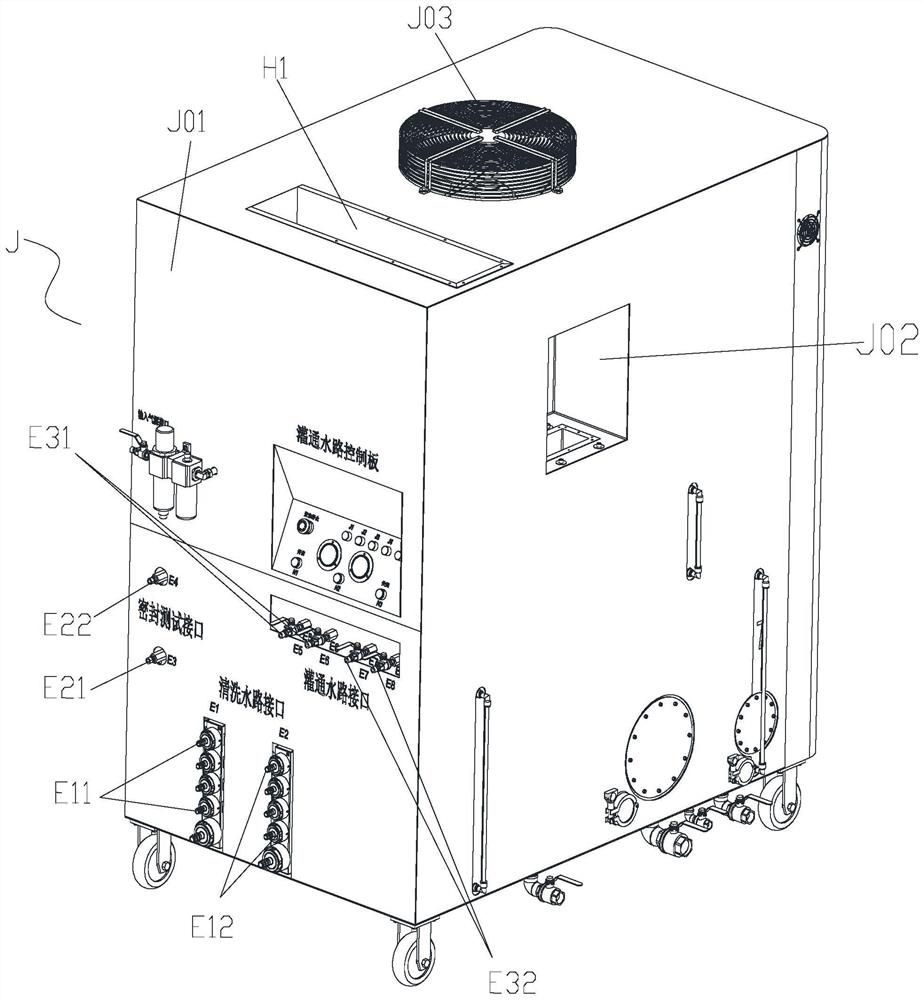

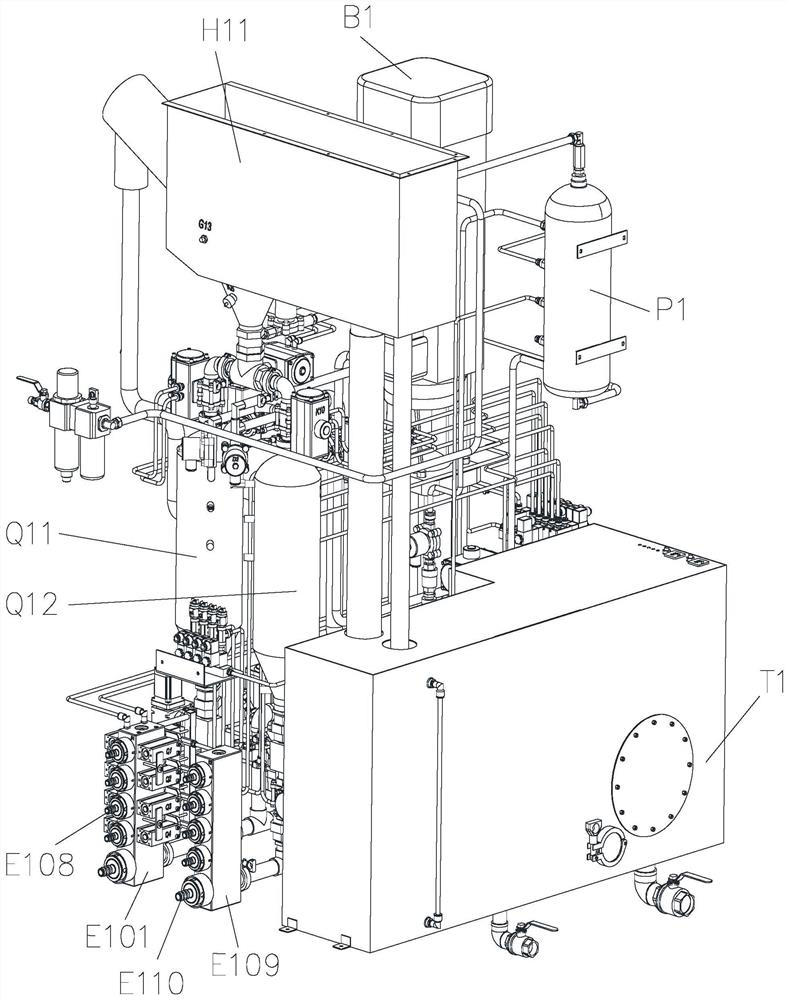

A multifunctional pipeline cleaning machine

A pipeline cleaning and multi-functional technology, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, and testing of machines/structural components, etc., can solve the problem of increasing the complexity of pipeline handling, reducing work efficiency, and the inability to accurately detect whether the pipeline is unblocked or not. To achieve sealing standards and other issues, to achieve the effect of strong practical value and market promotion value, high degree of integration and intelligence, and rich practical functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above objects and effects of the present invention and the generating means will be described in more detail in conjunction with the accompanying drawings clear, so that some people with knowledge in the art of the present invention pertains to facilitate the implementation of the technical idea of the present invention. The term used herein to illustrate embodiments and not to limit the invention. Wherein, in particular, should be noted that: as described herein and "connection" includes, but is not limited to the structure composed of connections between the elements, the signal connection relationship, and is herein "communication" refers between components via pipelines and other gaseous, liquid or solid fluid directly or indirectly "connected" or "continuous"; conduit between the components described herein and in "communication continuity" is a subordinate concept of "communication", which refers to directly or indirectly through oN or oFF, such as "valve" like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com