A New Manual Slip Device Used in Drilling and Workover

A slip, a new technology, applied in the direction of drilling equipment, drill pipe, drill pipe, etc., can solve the problems of slips not matching well, slips cannot be placed, etc., easy to install and practical application, the effect is obvious , The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

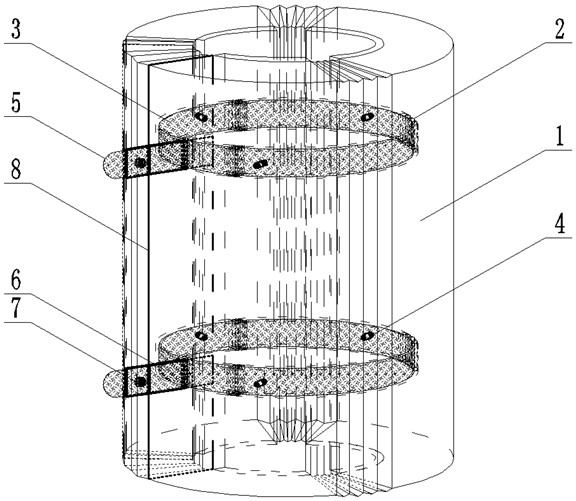

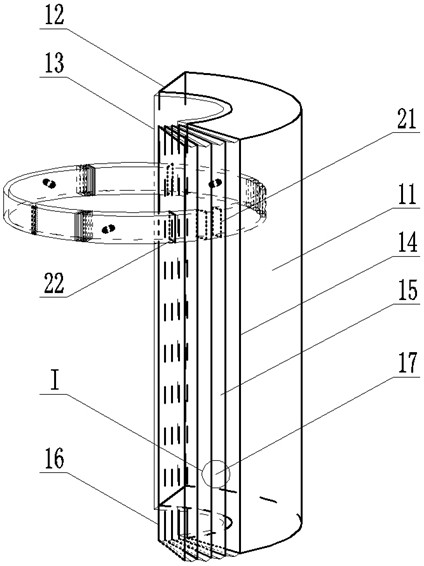

[0027] The cross section of the slip body segment in the embodiment of the present invention is a double fan ring, and the longitudinal section is square.

[0028] The number of slip body segments in the embodiment of the present invention is not limited. Under the condition that the arc length of the cross-section fan is the same, the more the number, the larger the diameter of the clamped or suspended target; The larger the diameter of the suspended target.

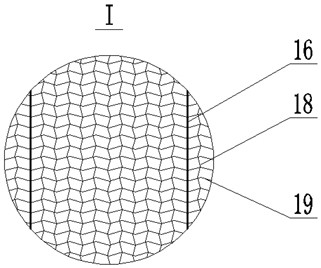

[0029] The longitudinal section of the accordion pleat silicone section in the embodiment of the present invention is square.

[0030] The number of accordion pleats in the embodiment of the present invention is not limited, but the number should be consistent with the number of slip body segments. Under the condition of the same cross-sectional arc length, the more the number, the larger the diameter of the clamped or suspended target; when the number is the same, the longer the cross-sectional arc length of a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com