Sealing element, door assembly and clothes treating apparatus

A technology of seals and doors, applied in sealing devices, mechanical equipment, engine sealing, etc., can solve problems such as poor sealing between barrels and seals, affecting user experience, water leakage, etc., to improve reliability and stability. performance, improve reliability and stability, increase area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

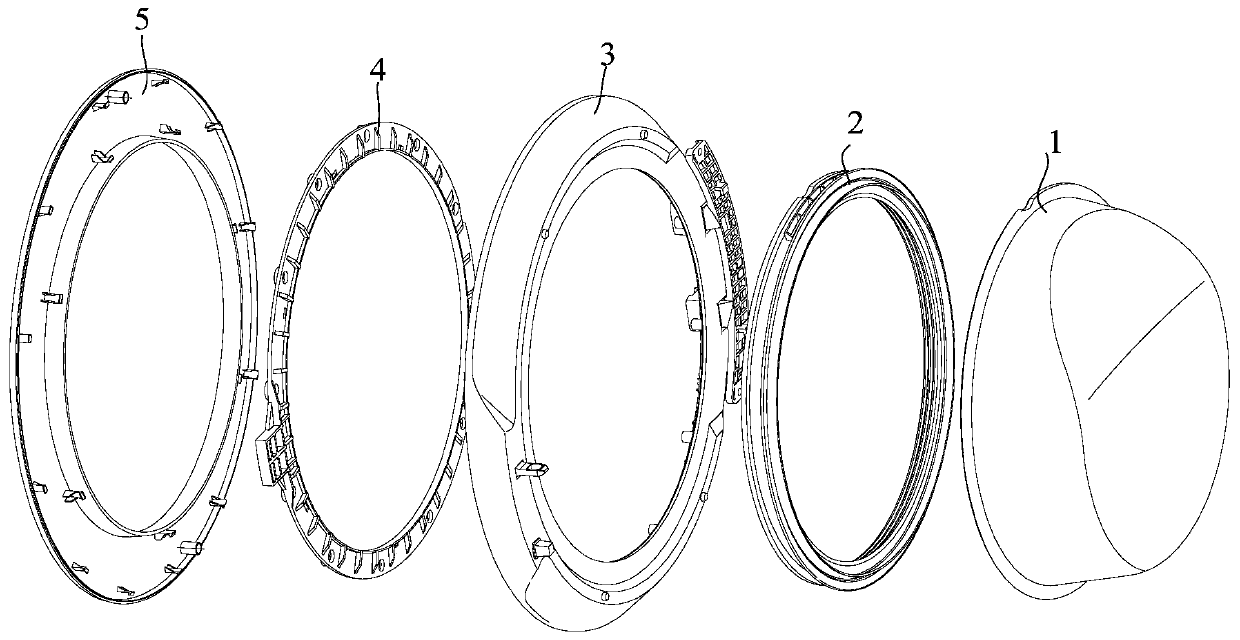

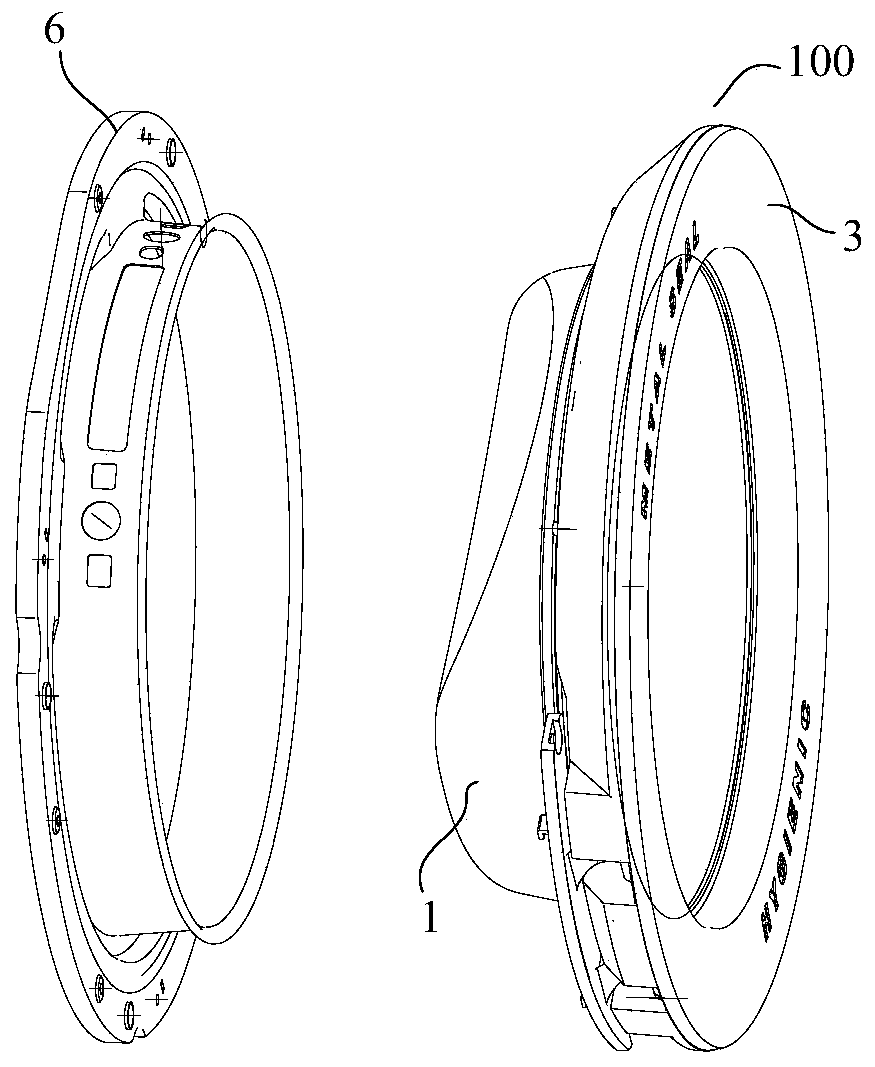

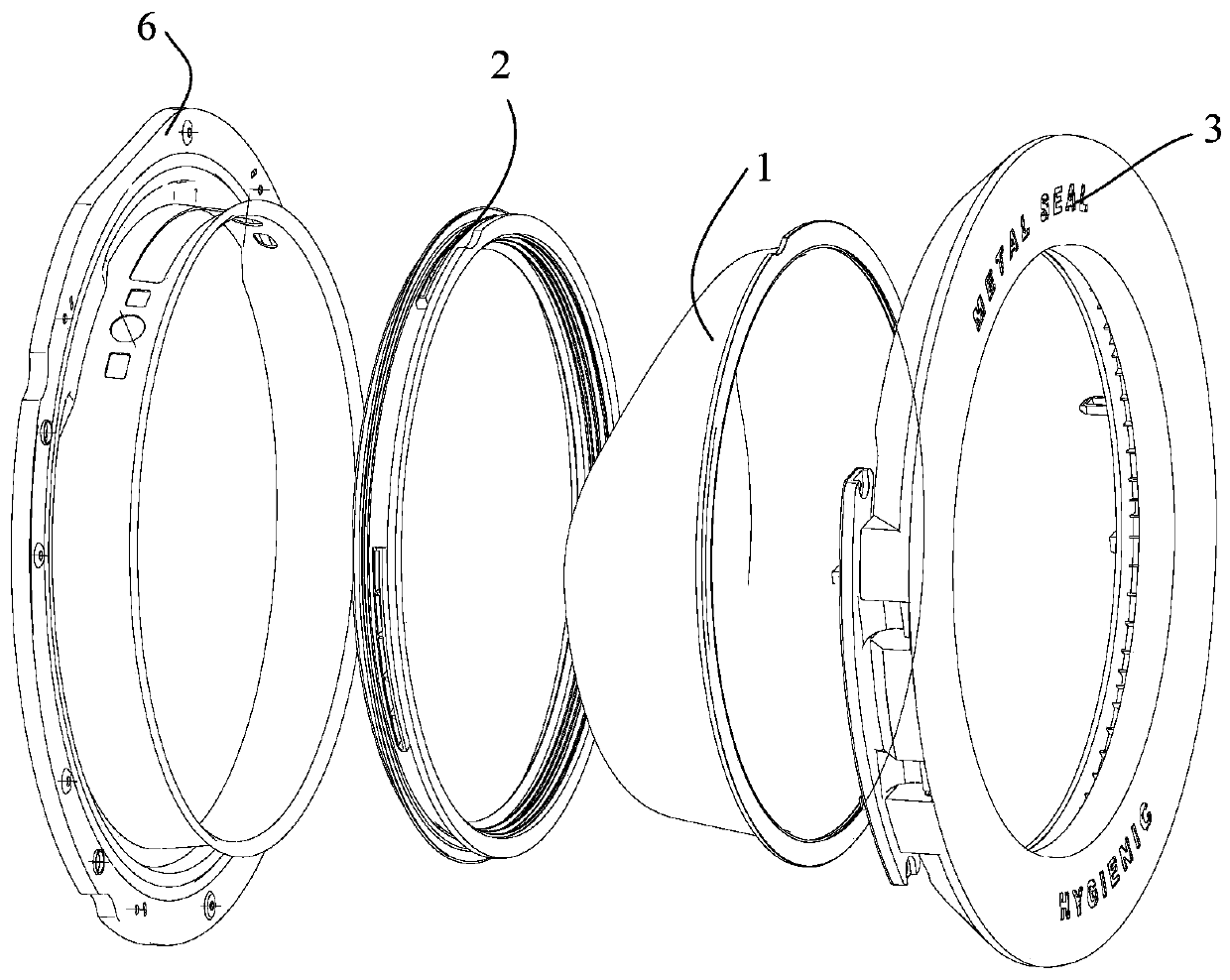

[0053] Such as figure 1 As shown, a sealing member 2 provided according to some embodiments of the present invention is used for sealing between a door body (first body) and a bucket body (second body), including a sealing part and a stopper part 25 .

[0054] The sealing part is used for sealing the bucket body.

[0055] The stopper 25 is connected with the sealing part, and the stopper 25 is configured such that the barrel body cooperates with the sealing part, and the barrel drives the sealing part to move and stop against the stopper part 25 .

[0056] The sealing member 2 provided by the above-mentioned embodiments of the present invention includes a sealing part and a stopper 25. The sealing part is used to abut against the barrel body to play a sealing role. When the barrel body abuts against the sealing part, the barrel body can drive the sealing part. part moves and resists against the stopper part 25, and the stopper part 25 plays a supporting role to limit the furt...

Embodiment 2

[0061] In addition to the features of the above-mentioned embodiments, this embodiment further defines that: the sealing member 2 includes: an annular sealing body 21 , and the sealing portion and the stop portion 25 are protrudingly provided on the outer wall of the sealing body 21 . Wherein, the direction close to the axis of the sealing body is inward, and the direction away from the axis of the sealing body is outward.

[0062] The sealing member 2 includes an annular sealing body 21, which is adapted to the shape of the door body, so that the sealing member 2 can be quickly installed and fixed on the door body. wall, so that the sealing part abuts against the barrel body, and realizes the abutment between the sealing part and the stopper part 25, thereby realizing the sealing function of the sealing part and the supporting function of the stopper part 25. Moreover, the arrangement of the sealing part and the stop part 25 does not affect the cooperation between the sealing...

Embodiment 3

[0067] In addition to the features of any of the above-mentioned embodiments, this embodiment further defines: the stop portion 25 includes a first stop rib 25a and a second stop rib 25b, along the axial direction of the sealing body 21, the first stop rib 25a The first stop rib 25 a and the second stop rib 25 b are arranged in sequence along the circumferential direction of the sealing body 21 .

[0068] The sealing portion is in the form of a ring arranged along the circumferential direction of the sealing body 21 , and the first stop rib 25 a and the second stop rib 25 b are arranged along the circumferential direction of the sealing body 21 , so as to support the entire ring of the sealing portion. The provision of the first stop rib 25a and the second stop rib 25b can enhance the support strength of the sealing part.

[0069] The first stopper rib 25a is in the form of an annular ring arranged along the circumferential direction of the sealing body 21. At this time, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com