Internal Gear Pump Type Circulating Cooling Magnetorheological Fluid Brake

An internal gear pump and magneto-rheological fluid technology, applied in the direction of liquid resistance brakes, brake types, brake components, etc., can solve the problems of poor brake stability and poor braking effect, so as to avoid temperature rise and improve stability The effect of sex and braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

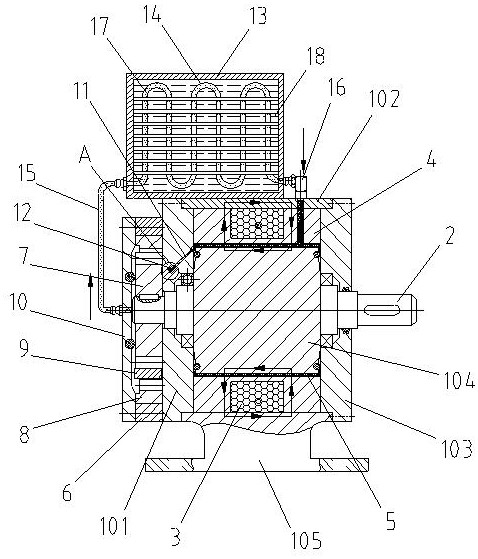

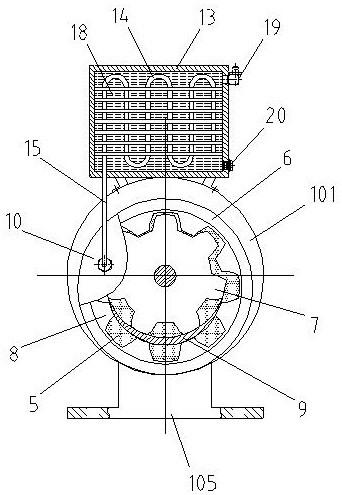

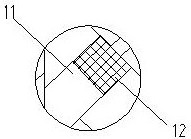

[0020] Example: see Figure 1 to Figure 3 , an internal gear pump type circulating cooling magneto-rheological fluid brake, comprising a brake housing, a brake shaft 2, an excitation coil 3, a coil mounting ring 4 and a magneto-rheological fluid 5. The brake housing includes a left end cover 101, an outer cylinder 102 and a right end cover 103 connected in sequence; a base 105 is also provided on the lower side of the outer cylinder 102, and the base 105 is integrally formed with the outer cylinder 102, and the base 105 There are several installation holes on the top, so that the base 105 and the whole brake housing can be fixed on the ground or other places conveniently. The brake shaft 2 is located in the brake housing, and is connected with the left end cover 101 and the right end cover 103 through bearings, and the two ends of the brake shaft 2 pass through the left end cover 101 and the right end cover 103 respectively. The diameter of the part of the brake shaft 2 locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com