Supporting structure and display device

A support structure and flexible display technology, which is applied in the direction of identification devices, supporting machines, machine tables/supports, etc., can solve the problems of lower reliability and stability, bending resistance, and poor impact resistance, so as to improve reliability and Stability, enhanced impact resistance, and reduced processing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

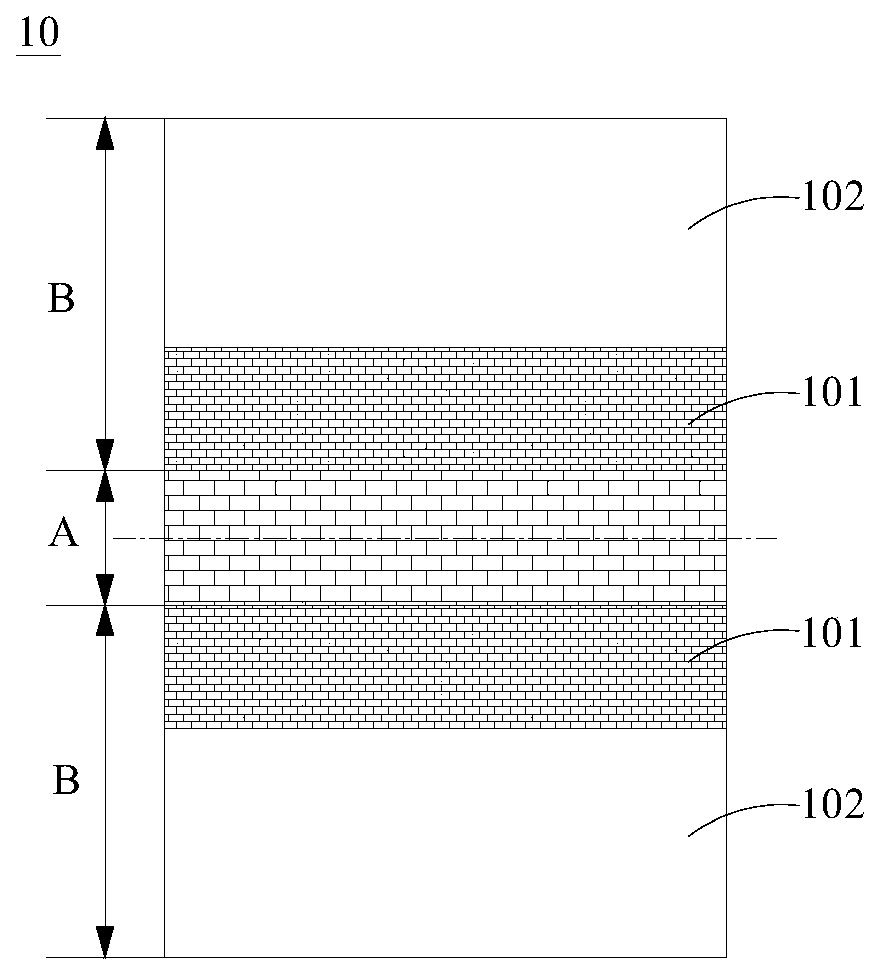

[0059] Such as figure 1 As shown, the first hollow holes in the bendable region A of the support structure 10 are arranged at equal intervals to ensure that the bendable region A can evenly disperse the stress during the bending process and avoid the occurrence of stress in the bendable region A. In the case of damage; in the same way, the second hollow holes of the buffer portion 101 in the fixed area B of the support structure 10 are arranged at equal intervals to ensure that the buffer portion 101 can disperse the stress more evenly during the bending process and avoid buffering. In the event of damage at the portion 101, the structural stability of the support structure 10 is ensured.

[0060] In this embodiment, the rigidity of the buffer portion 101 is slightly greater than the rigidity of the bendable region A, so that while eliminating or weakening the sudden change in rigidity at the junction of the fixed region B and the bendable region A, the support stability of th...

Embodiment 2

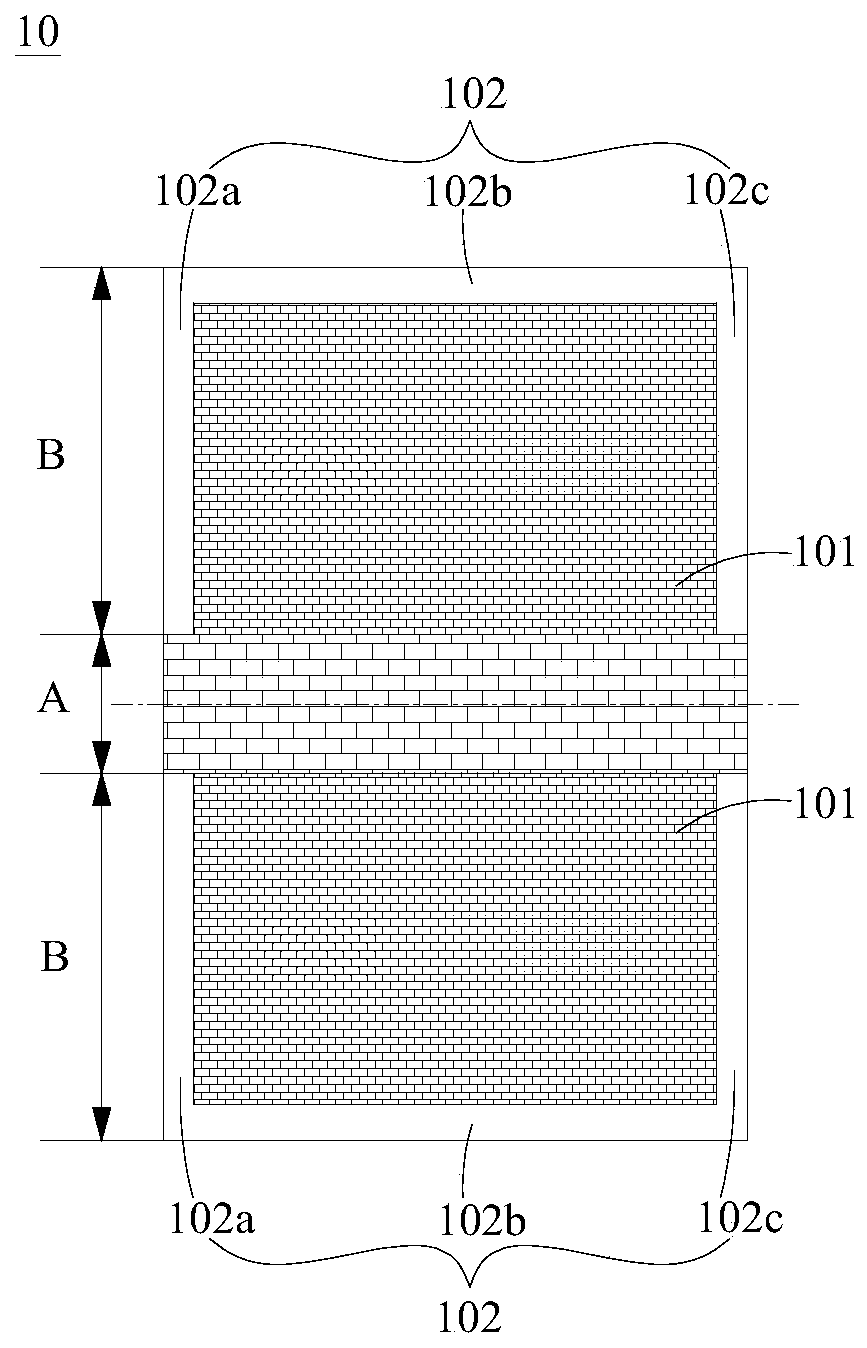

[0064] The main difference between the second embodiment and the first embodiment is: the shape of the rigid holding part 102 in the fixed area B, the positional relationship between the rigid holding part 102 and the buffer part 101, the area ratio, etc.; while other design methods are the same as those of the first embodiment The same, for example: the pattern of the buffer portion 101 , the pattern of the bendable region A, the rigid relationship between the buffer portion 101 and the bendable region A, and so on. However, it should be understood that other design methods may not be the same as in the first embodiment, as long as the general design requirements of the present application can be met.

[0065] Only the differences between this embodiment and the first embodiment will be described in detail below.

[0066] Such as figure 2 As shown, the rigid holding portion 102 in the fixing area B is in the shape of a U-shaped strip, and the U-shaped rigid holding portion ...

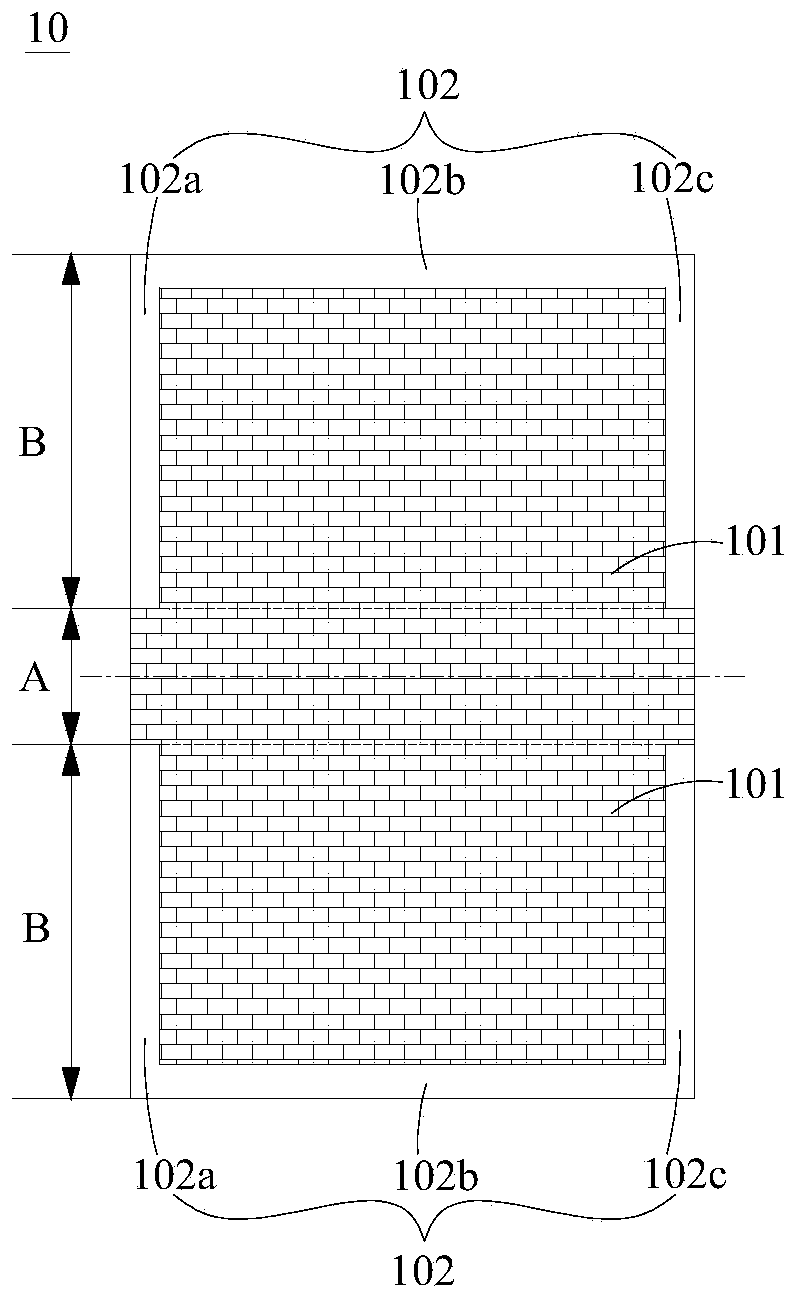

Embodiment 3

[0069] The main difference between the third embodiment and the second embodiment is: the rigid relationship between the buffer portion 101 in the fixed area B and the bendable area A, etc.; and other design methods are the same as the second embodiment, for example: the bending area A The pattern, the shape of the rigid holding portion 102 in the fixed area B, the positional relationship and area ratio between the rigid holding portion 102 and the buffer portion 101 , etc. However, it should be understood that other design methods may not be the same as in Embodiment 2, as long as the general design requirements of the present application can be met.

[0070] Only the differences between this embodiment and the second embodiment will be described in detail below.

[0071] Such as image 3 As shown, the rigidity of the buffer portion 101 is equal to the rigidity of the bendable region A, so as to basically eliminate the sudden change in rigidity at the junction of the fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com