Two tier automatic cost estimation for automatic manufacture of spare parts

A manufacturing cost, automatic manufacturing technology, applied in the field of double-layer automatic cost estimation for automatic manufacturing of spare parts, can solve the problems of time-consuming, inefficient and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

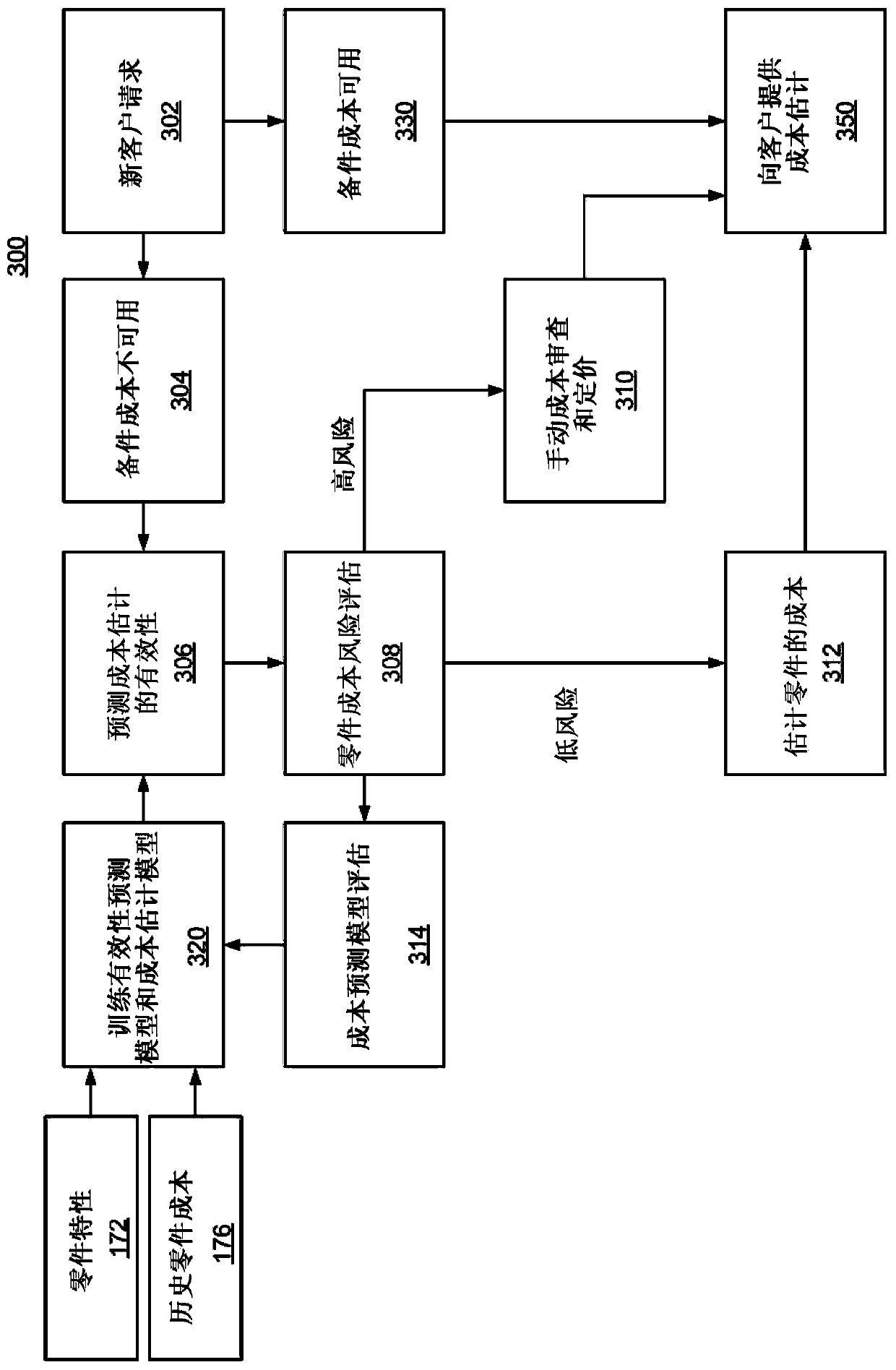

[0074] Clause 1. A method for the automatic manufacture of mechanical parts, the method comprising the steps of:

[0075] using one or more computer processors to generate a first estimate of a manufacturing cost of a first machine part using a first machine learning model;

[0076] determining that the first estimate of manufacturing cost of the first machine part falls within the validity range of the first machine learning model, and in response, using the one or more computer processors to generate the first machine learning model using the second machine learning model. A second estimate of the manufacturing cost of the part;

[0077] determining an expected cost error in the second estimate of the manufacturing cost of the first machine part; and

[0078] Automatic manufacture of the first mechanical part is caused upon determining that the expected cost error falls within a predetermined acceptable range.

[0079] Clause 2. The method of Clause 1, wherein the step of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com