Thermal insulation protection type carrier communication submarine cable

A carrier communication, submarine cable technology, applied in the direction of submarine cables, communication cables, insulated cables, etc., can solve the problems of short heat preservation period, surface damage, cable erosion, etc., to reduce the degree of corrosion, improve stability, insulation performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

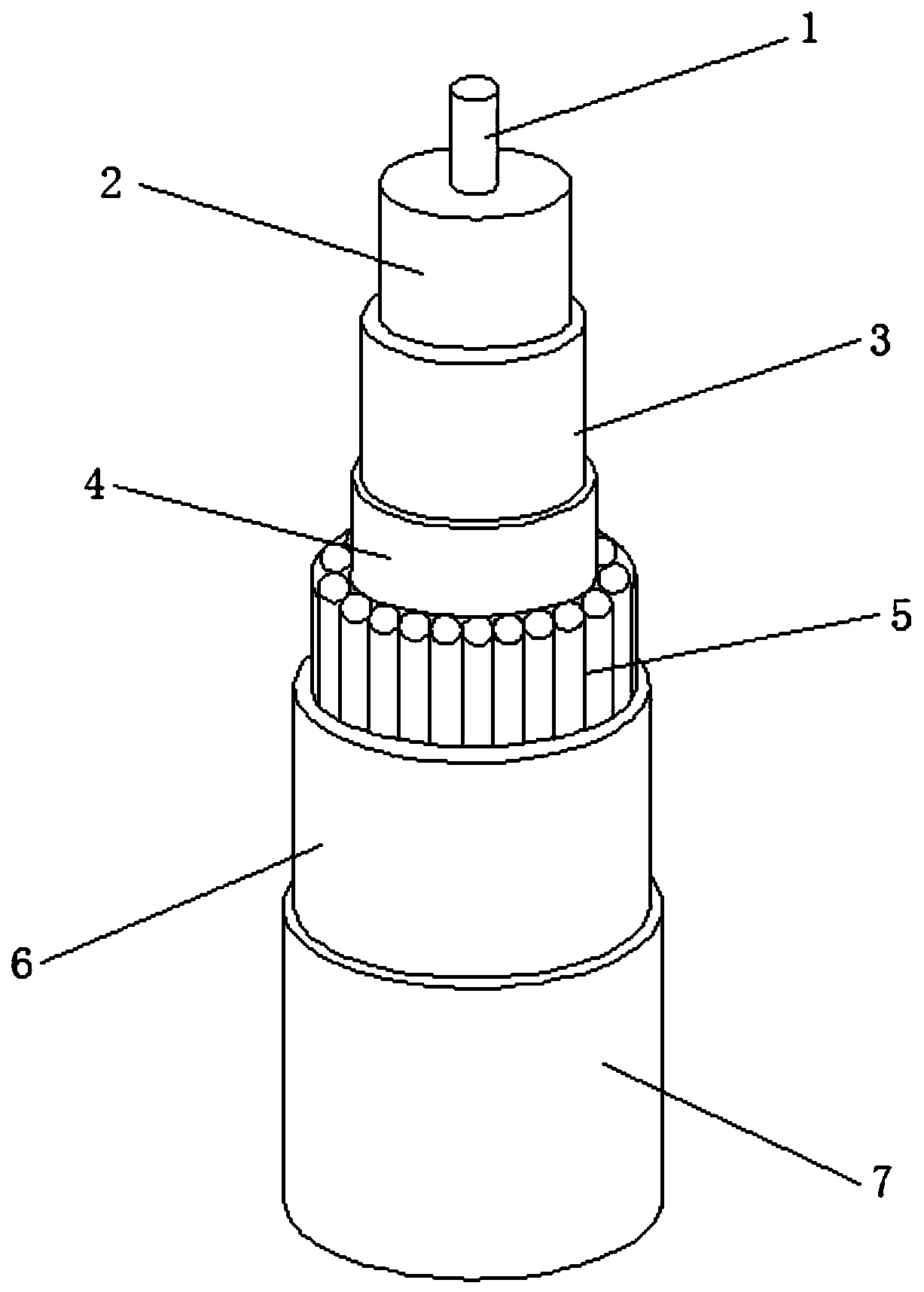

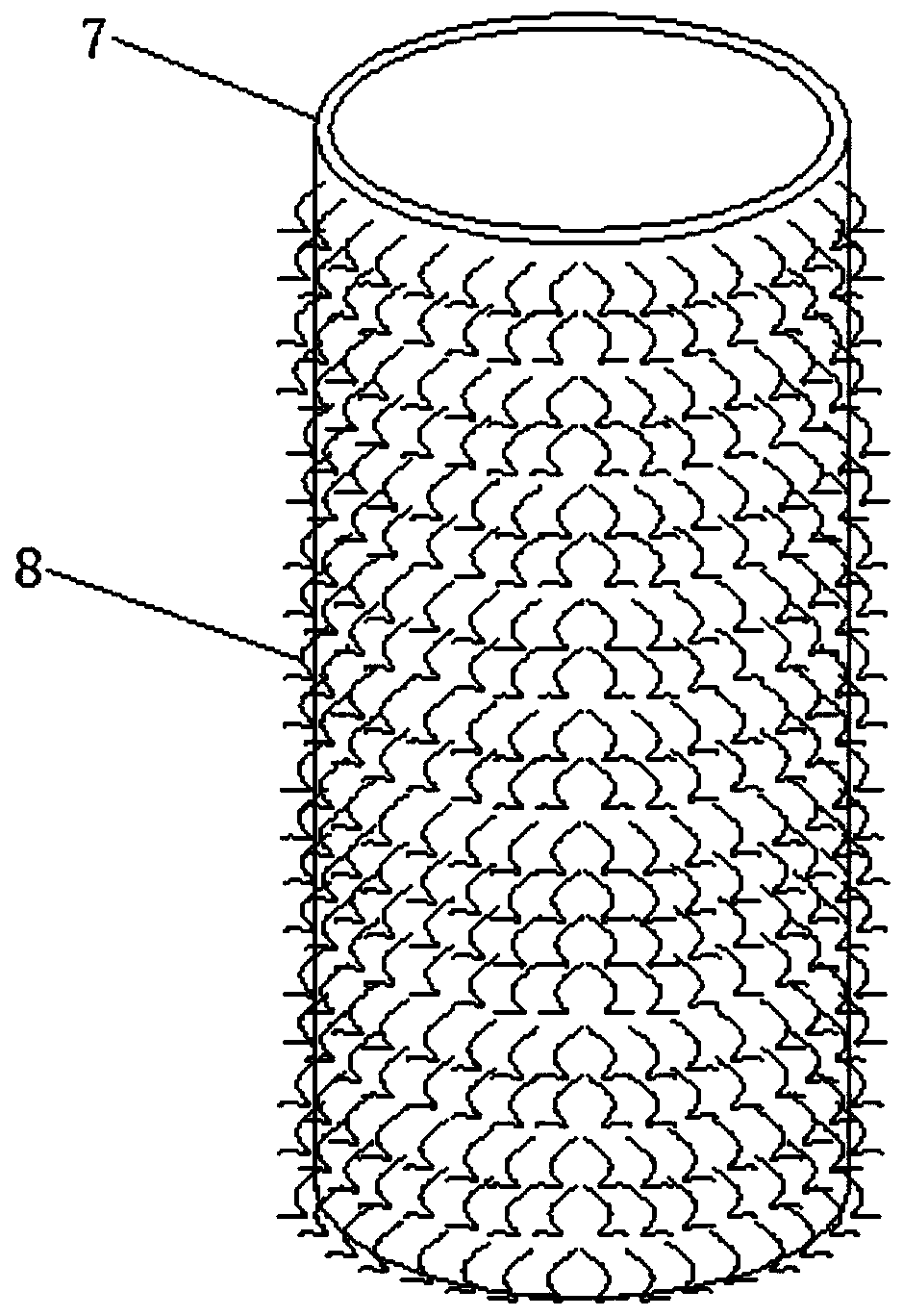

[0041] see figure 1 , a temperature-insulation-protected carrier communication submarine cable, comprising a center conductor 1, the center conductor 1 is wrapped with an inner layer insulator 2, an outer conductor 3, an intermediate sheath 4, an outer layer insulator 6 and an outer sheath from the inside to the outside in sequence 7, and the inner layer insulator 2, the outer conductor 3, the middle sheath 4, the outer layer insulator 6 and the outer sheath 7 are all evacuated into a vacuum, the outer layer insulator 6 is mixed with a pole insulation material, the middle sheath 4 and the outer sheath 7 A reinforced armor layer 5 is sandwiched between the layer insulators 6, and a vacuum is also drawn between the middle sheath 4, the reinforced armor layer 5 and the outer layer insulator 6 to ensure the absolute airtightness inside the submarine cable. Please refer to figure 2 , the surface of the outer sheath 7 is densely covered with selective millipede claws 8, using extre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com