Motor drive control device, motor, and blowing device

A drive control and motor technology, applied in the fields of motors, air supply devices, and motor drive control devices, can solve the problems of time-consuming, repeated failures, etc., and achieve the effect of improving the success rate of starting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

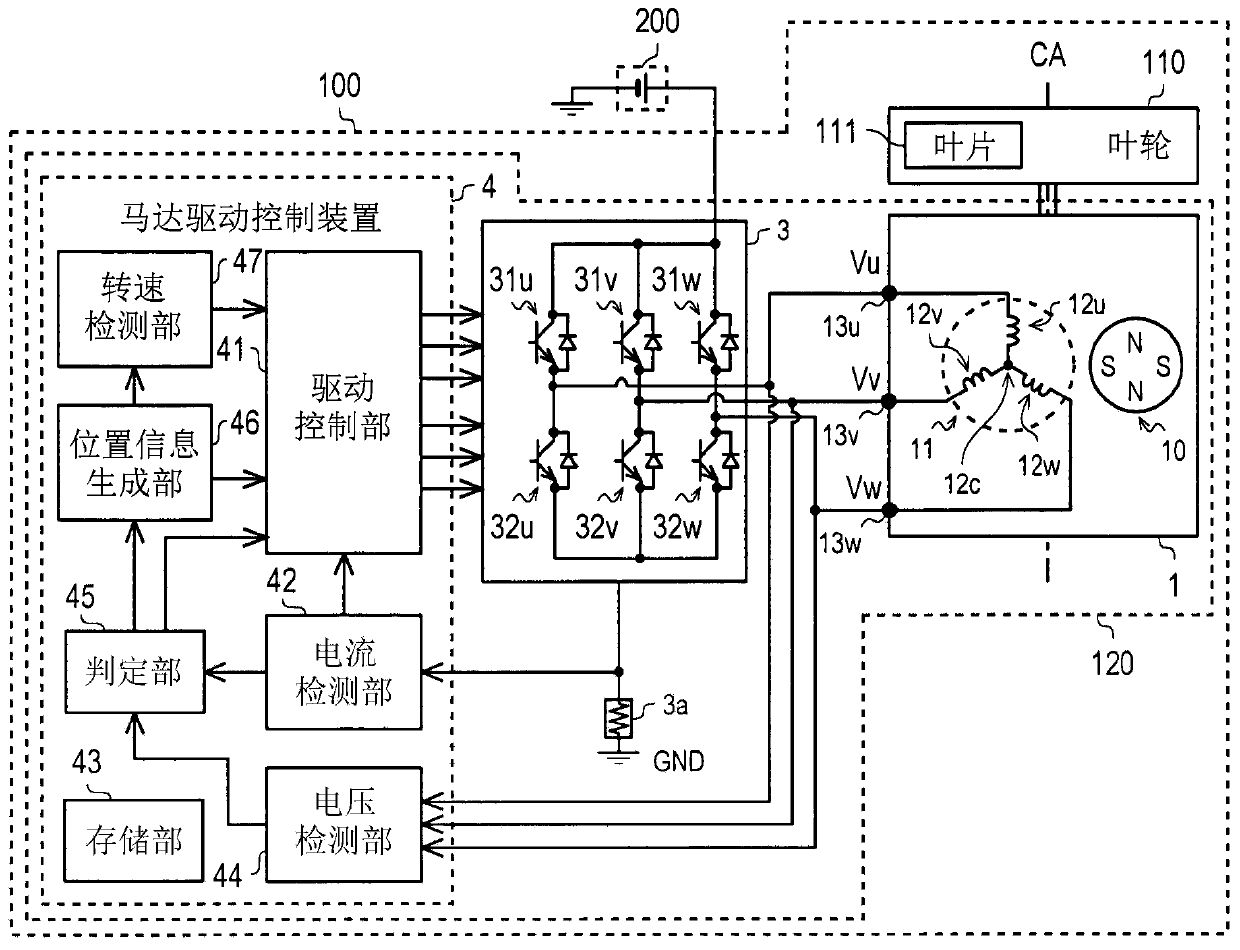

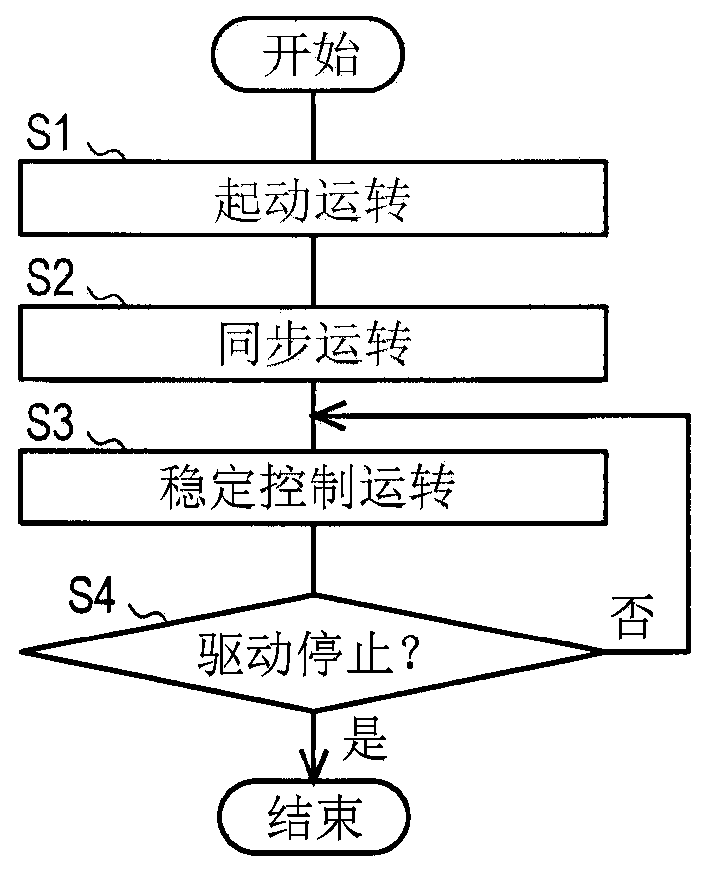

[0016] Hereinafter, exemplary embodiments of the present invention will be described with reference to the drawings.

[0017] In addition, in this specification, in the air blower 100, the direction parallel to the central axis CA of rotation of the motor part 1 and the blade 111 is called "axial direction."

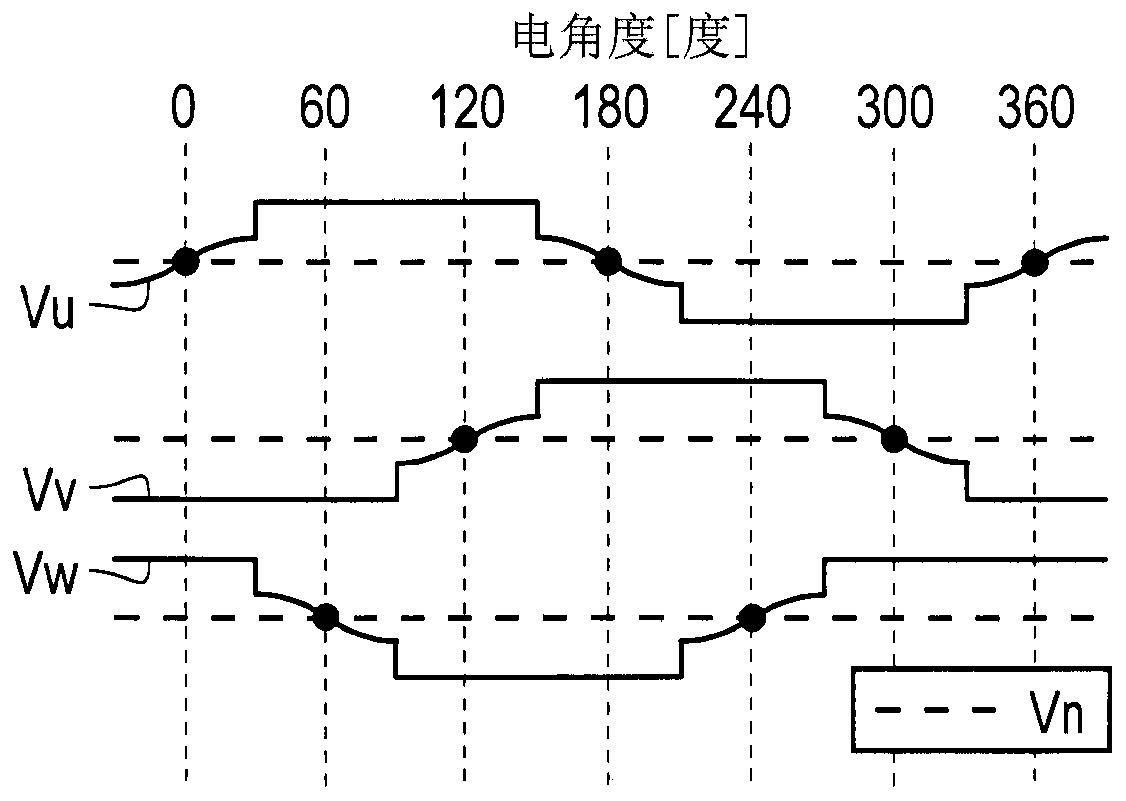

[0018] The U-phase winding 12u, the V-phase winding 12v, and the W-phase winding 12w of the stator 11 of the motor unit 1 may be individually or collectively referred to as a phase winding 12 . The phase that energizes the phase winding 12 in the three-phase AC voltage is called an energized phase, and the phase that does not energize the phase winding 12 is called a non-energized phase. In addition, the combination of two energized phase windings 12 is called an energization pattern. In addition, the U-phase voltage, the V-phase voltage, and the W-phase voltage of the three-phase AC voltage are sometimes called phase voltages individually or collectively.

[0019]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com