Energy-saving and environment-friendly sulfur removal machine for power plant

An energy-saving and environmental protection, power plant technology, applied in the direction of dispersed particle separation, chemical instruments and methods, dispersed particle filtration, etc., can solve the problems of air pollution, simple structure, large energy consumption, etc., to save electric energy, improve the effect, reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

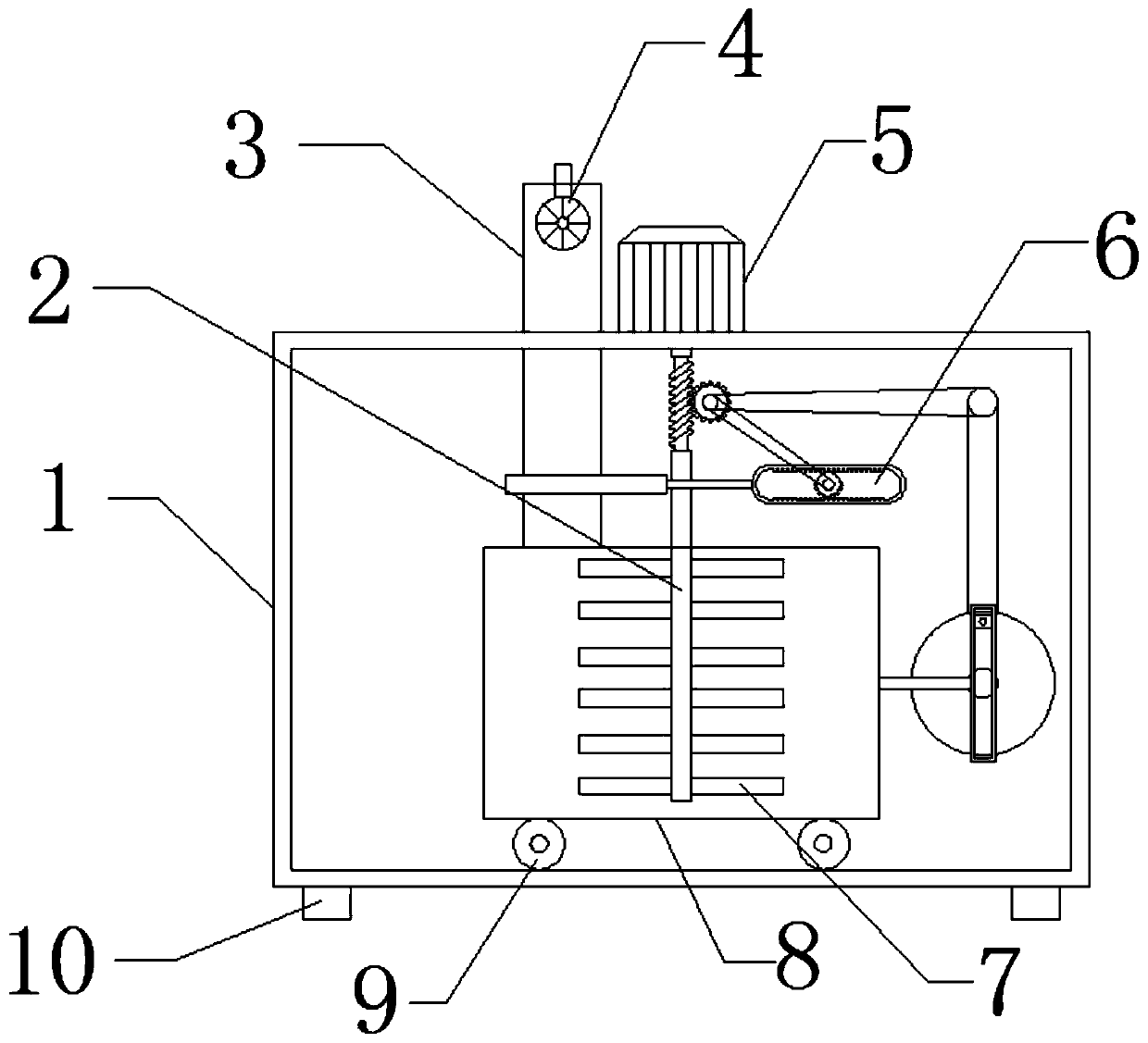

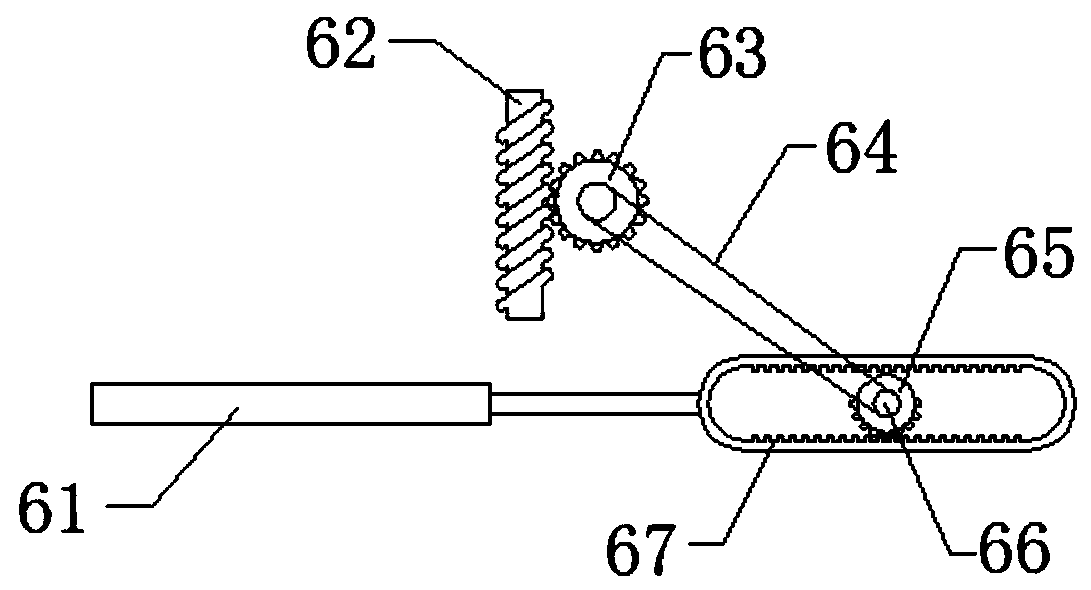

[0020] see figure 1 and figure 2 , the present invention provides a technical solution: an energy-saving and environment-friendly desulfurizer for power plants, including a device main body and a filter mechanism 6, the device main body includes a box body 1 hinged with a side door, a rotating shaft 2, an air inlet 3, Inlet fan 5, motor 5, stirring blade 7, mixing bucket 8 hinged with a side door and a leg 10, the leg 10 is arranged on the bottom end surface of the box body 1, the mixing bucket 8 is located inside the box body 1, and the air inlet 3 runs through the box body 1 and communicates with the inside of the mixing barrel 8, the air intake fan 5 is located inside the air inlet 3, the motor 5 is arranged on the top surface of the box body 1, and the rotating shaft 2 is rotatably connected inside the box body 1, And the rotating shaft 2 runs through the box body 1, and is fixedly connected with the output end of the motor 5, the stirring blade 7 is arranged on the annu...

Embodiment 2

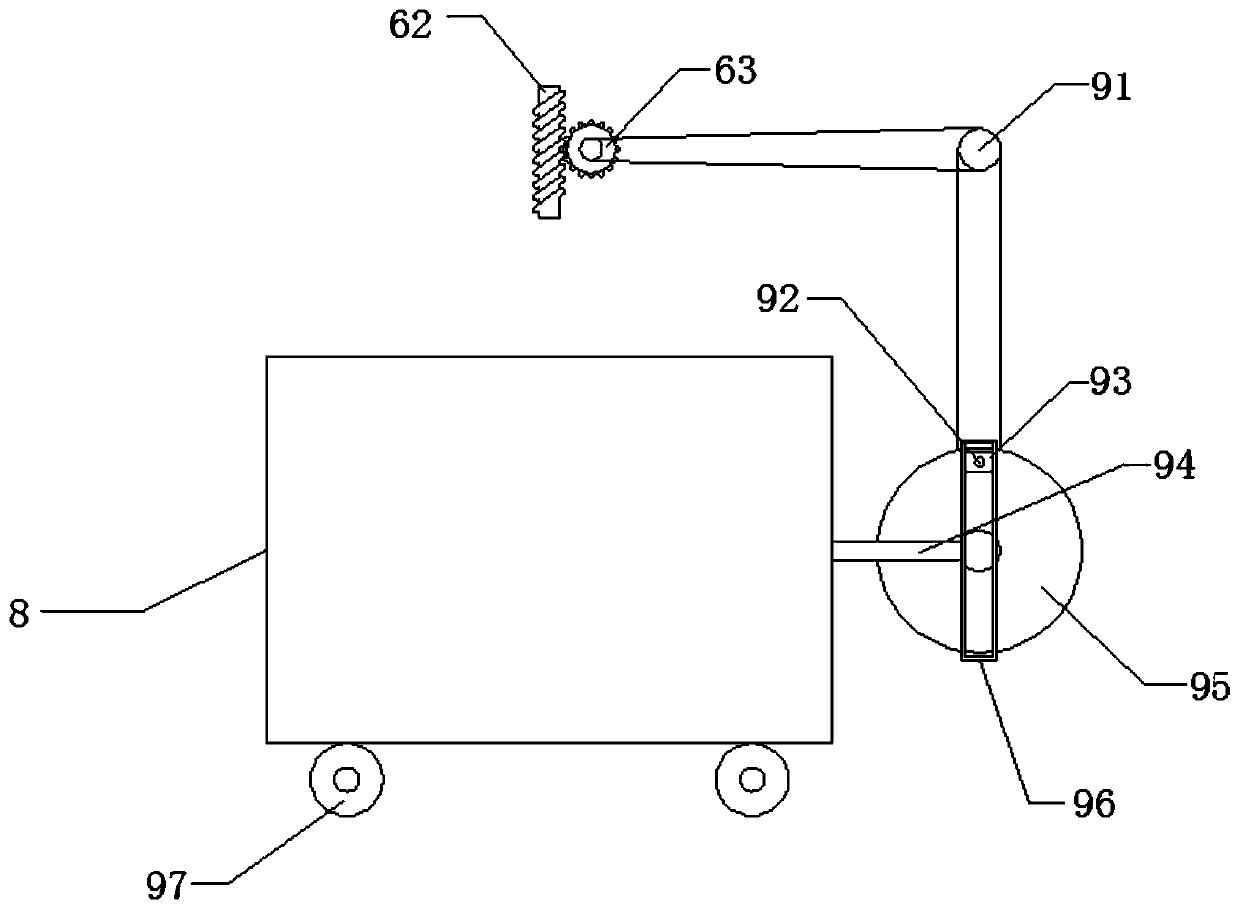

[0025] As a preferred solution of Embodiment 1, please refer to figure 1 and image 3 , the desulfurizer also includes an auxiliary stirring mechanism 9; the auxiliary stirring mechanism 9 includes a transmission shaft 91, a pin shaft 92, a slider 93, a transmission rod 94, a turntable 95, a sliding bar 96 and a road wheel 97; the transmission shaft 91 is rotatably connected to the inside of the casing 1, and the turntable 95 is rotatably connected to the inside of the casing 1. The transmission shaft 91 is respectively connected to the shaft of the turntable 95 and the turbine 63 through a synchronous belt, and the slide bar 96 is slidably connected to the Inside the box body 1, the slide bar 96 is fixed to the mixing bucket 8 through the transmission rod 94, and the slide block 93 is slidably connected to the inside of the slide bar 96, and the slide block 93 is connected to the surface of the turntable 95 through a pin shaft 92 for rotation, The mixing bucket 8 is slidably...

Embodiment 3

[0029] As a preferred solution of embodiment one or two, please refer to figure 1 , figure 2 , image 3 and Figure 4 , the desulfurizer also includes a pulley 11, a rope 12 and a spring 13; the two ends of the spring 13 are respectively closely connected with the mixing barrel 8 and the inner wall of the box body 1, the pulley 11 is slidably connected inside the box body 1, and the rope 12 One end is closely connected with the ring rack 67, the other end of the rope 12 is closely connected with the mixing bucket 8, and the rope 12 is wrapped on the outer surface of the pulley 11;

[0030] There are several springs 13, and several springs 13 are evenly arranged on the inner wall of the mixing bucket 8 and the box body 1;

[0031]Working process: when the ring rack 67 moves to the left, the mixing bucket 8 is pulled to slide to the right through the transmission of the rope 12 and the pulley 11, and when the ring rack 67 moves to the right, the spring 13 pulls the mixing bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com