An external card type cutting machine for pipe cutting

A technology of pipe cutting and cutting machine, which is applied to pipe shearing devices, shearing devices, metal processing machinery parts, etc., can solve problems such as electrical hazards of metal powder, and achieve the effect of ensuring tightness, improving export, and reducing dust diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

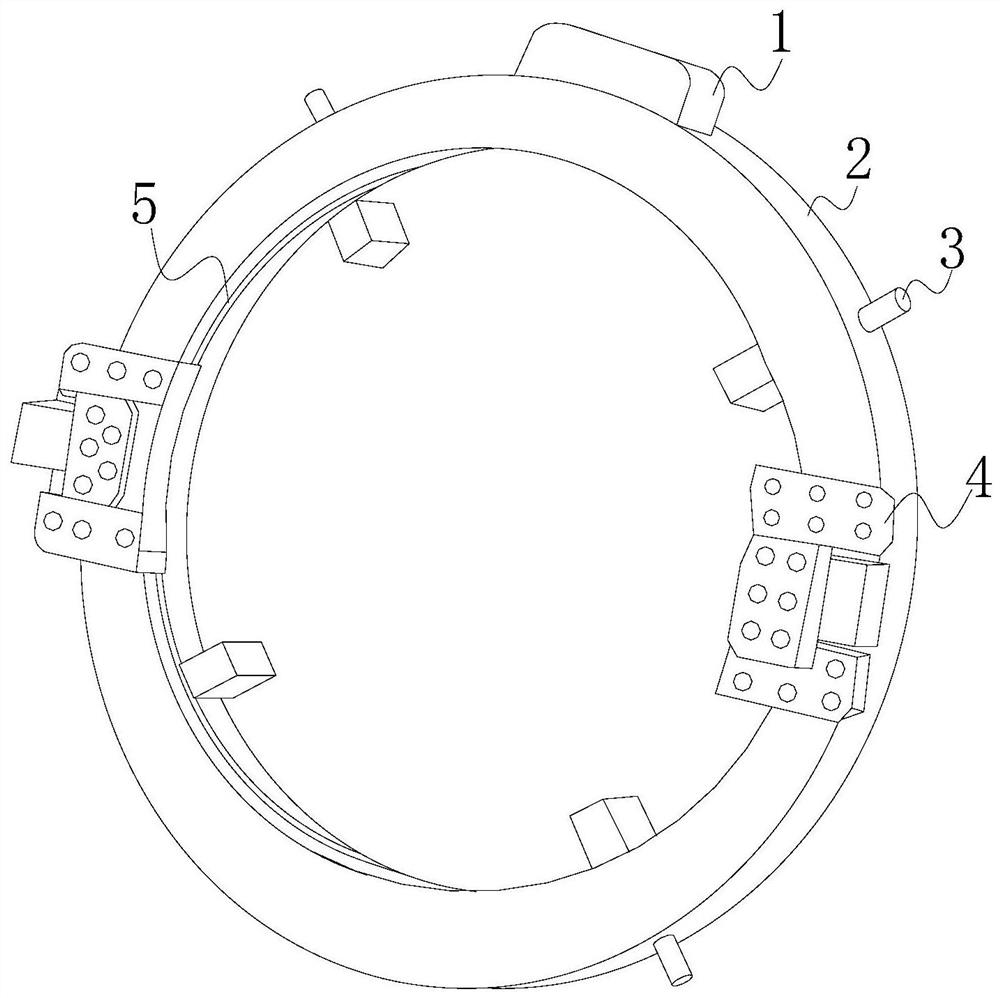

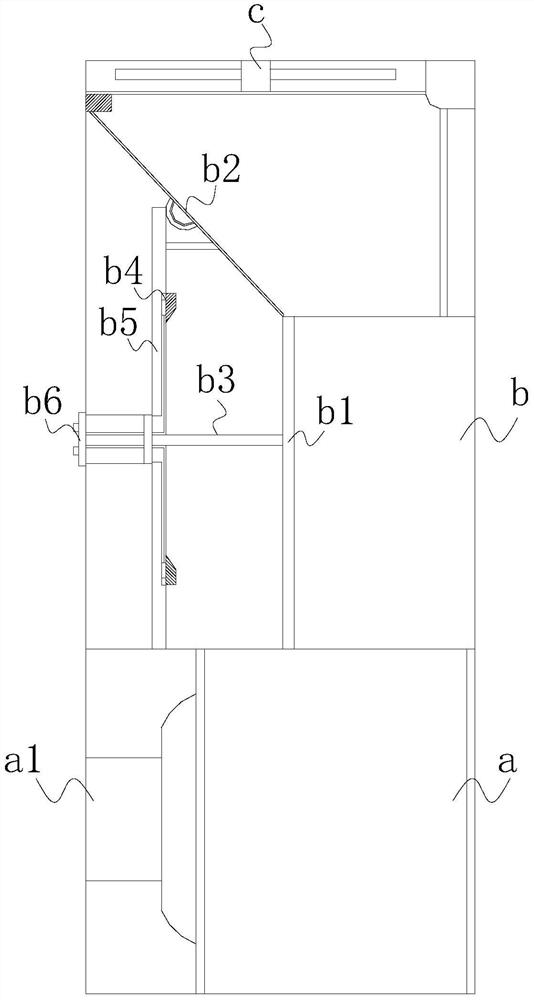

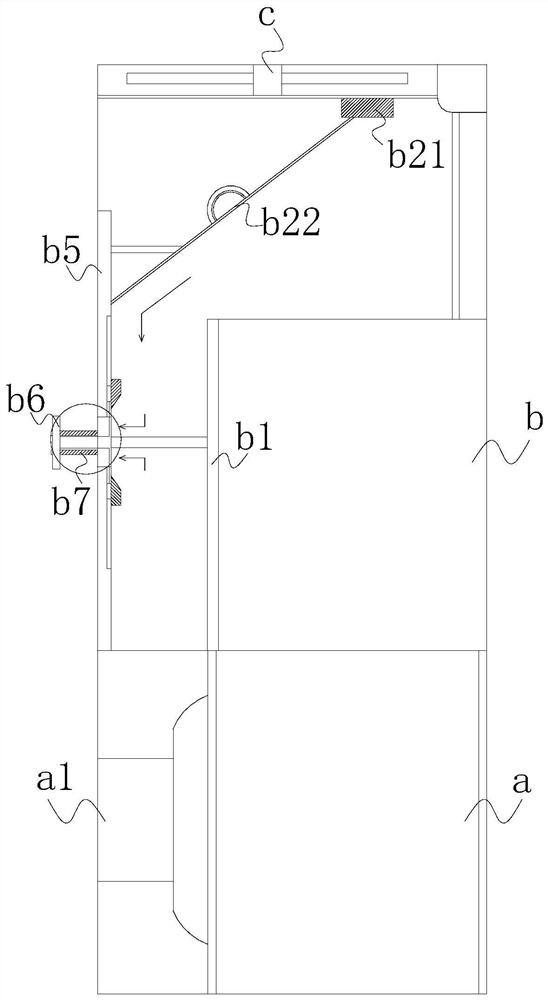

[0032] Such as Figure 1-Figure 7 As shown, the present invention provides a kind of external clip type cutting machine for pipe cutting, its structure includes driver 1, collar 2, fixture 3, clip 4, cutting slideway 5, and cutting slideway 5 is installed with cutting Knife, the cutting slideway 5 and the collar 2 are integrally formed, the clamp 3 is provided with four, and evenly mechanically connected to the collar 2 to cooperate with the pipeline, and the collar 2 is two equal semicircles The shape structure is fixed by the clip 4, the driving machine 1 is installed on the collar 2 to drive the cutting knife, the inside of the driving machine 1 is driven by the motor a, the motor a is fixed with the base a1, and the motor a is equipped with a vent b and a cooling fan c, and the vent b is provided with a first partition b1, a movable sloping plate b2, a connecting rod b3, a push-pull body b4, a second partition b5, a sealing member b6, a spring Axis b7, the first partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com