V-shaped diamond end-mill and machining method

A technology of diamond and gong knife, which is applied in the direction of wood processing equipment, manufacturing tools, rotary cutting tools, etc., can solve the problems of easy processing marks, poor processing effect, short service life, etc., and achieve good cutting effect and easy processing and grinding , the effect of high service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

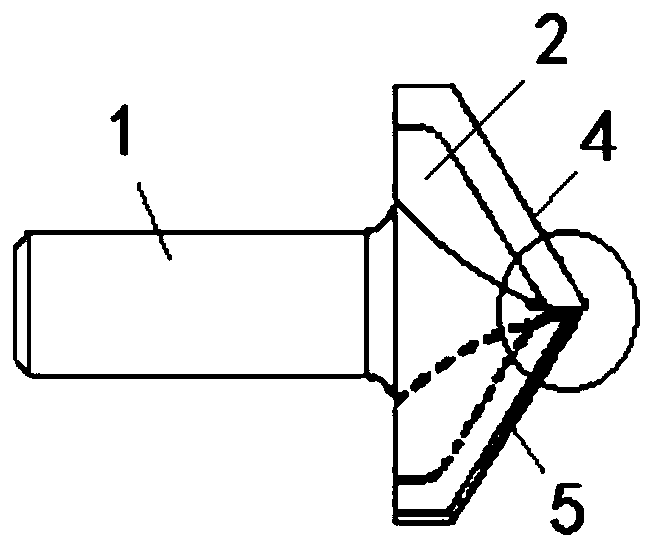

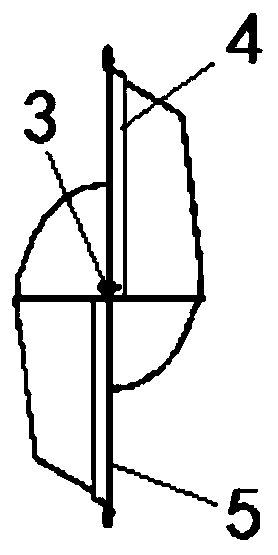

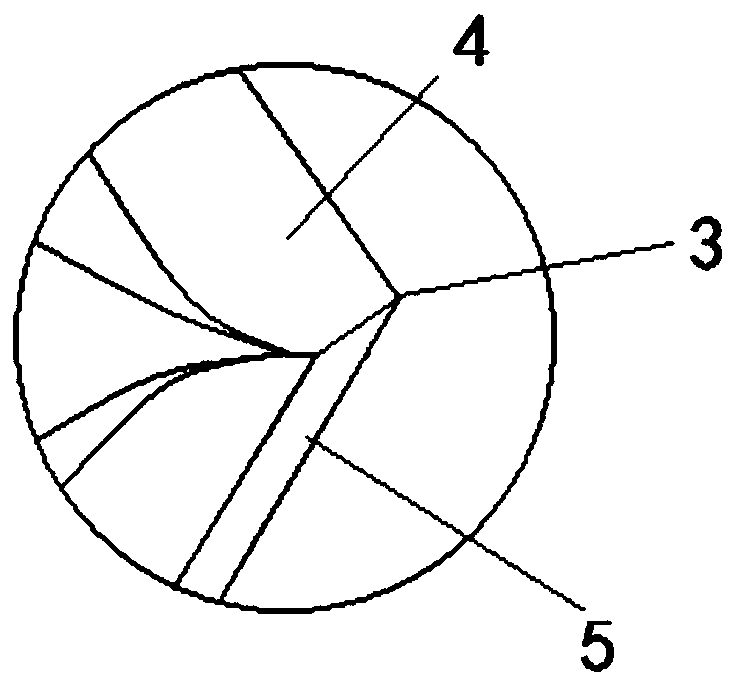

[0018] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 Shown, a kind of diamond V-shaped gong cutter, cutter body 1 and the left PCD blade 5 and the right PCD blade 4 that are welded on the cutter head 2 form a V-shaped angle between the left PCD blade 5 and the right PCD blade 4, and The left PCD blade 5 and the right PCD blade 4 are asymmetrical, the sharp point 3 of the right PCD blade 4 is on the central axis, the right PCD blade 4 crosses the central axis by 1mm, the left PCD blade 5 does not pass the central axis, and is just in line with the right PCD blade 4 connections, together form a V-shaped cutting edge.

[0019] A method for processing a diamond V-shaped gong knife, comprising the following steps: welding a left PCD blade 5 and a right PCD blade 4 on the top of the cutter head, the sharp point of the right PCD blade 4 is on the central axis, the left PCD blade 5 does not pass the central axis and It is connected with the right PCD blade 4 to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com