Full-automatic tunnel circumferential cutting equipment

A cutting equipment, fully automated technology, applied in tunnels, tunnel linings, mining equipment and other directions, can solve problems such as high safety risks and low efficiency, achieve high degree of automation, broad application prospects, and improve construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

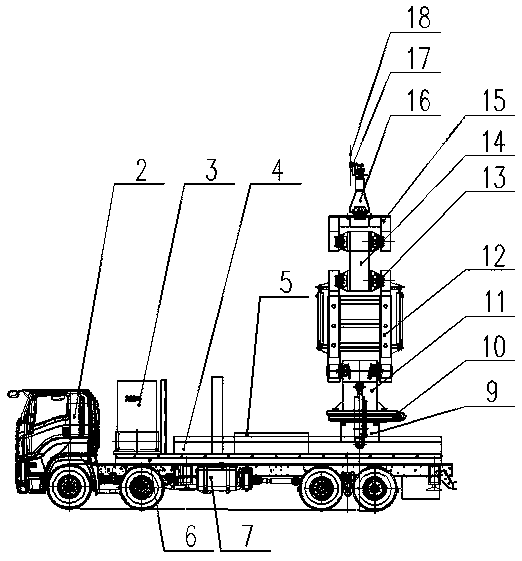

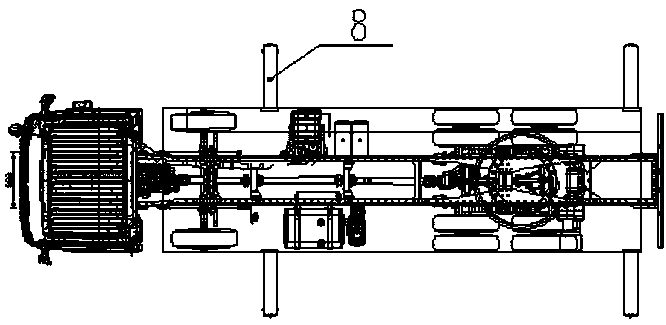

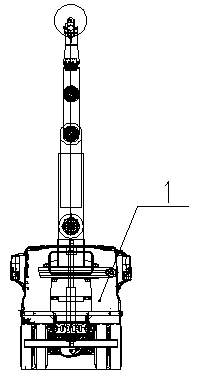

[0019] Such as Figure 1-3 As shown, a fully automatic tunnel circumferential cutting device of the present invention includes a vehicle running device 1, a sliding track 4, a sliding mechanism 9, a rotary device 10, a mechanical arm device, a rotary arm 16, a hydraulic wall saw 18 and a numerically controlled hydraulic system 7.

[0020] The automobile running device 1 comprises a car body 6, a driver's cab 2, a silent generator set 3, two water tanks and four hydraulic supporting legs 8. The upper rear of the car body 6 is provided with a sliding track 4, which can slide and change its position for the sliding mechanism 9. Two water tanks are arranged on both sides of the sliding track 4 and the upper middle of the car body 6, and are connected with the water cooling system 17, and are self-supplied. The driver's cab 2 is located at the front of the car body 6 , and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com