Steel dam gate opened and closed by direct connection type opening and closing machine

A hoist and direct-connection technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as construction and maintenance difficulties, increase the difficulty of technology, etc., achieve convenient maintenance and repair, convenient maintenance, and increase service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

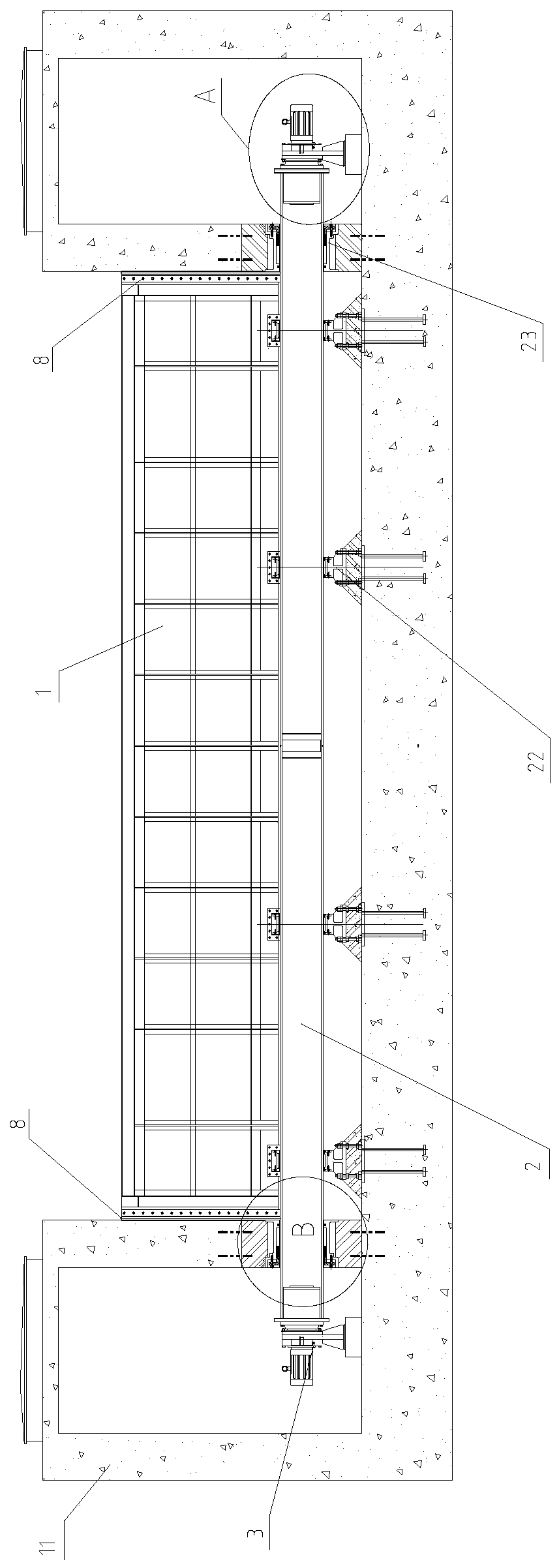

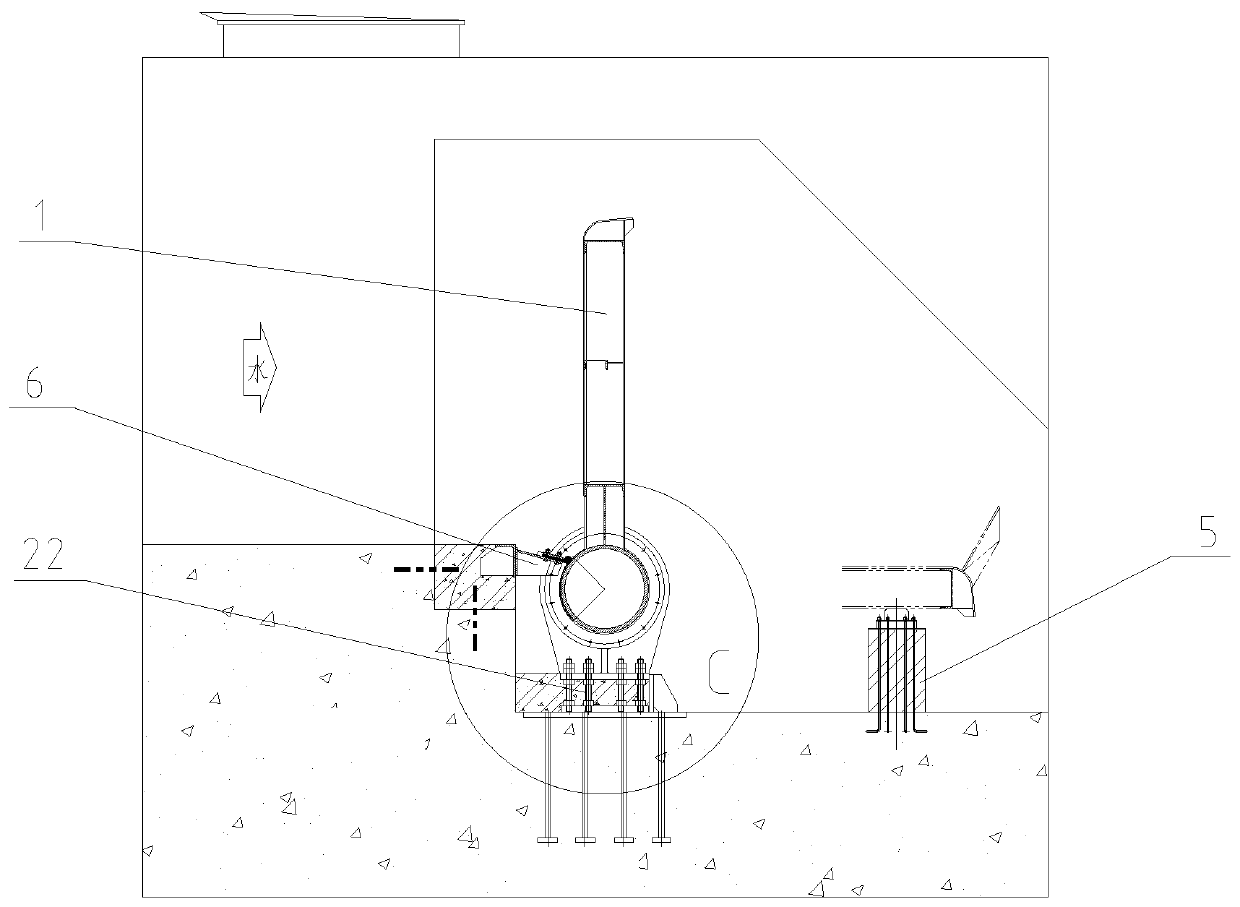

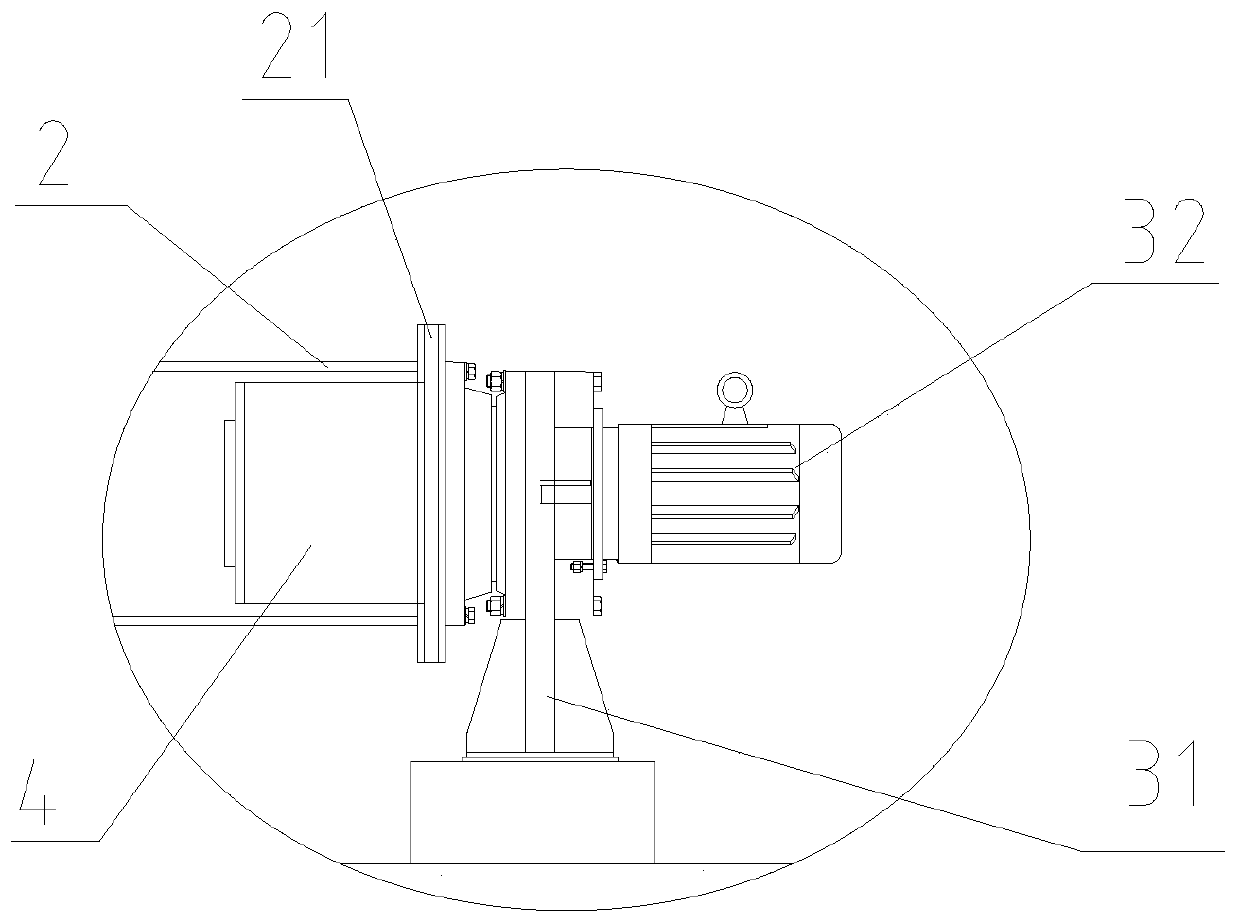

[0031] see Figure 1-Figure 5 , Figure 7 As shown, this embodiment provides a direct-coupled hoist for steel dam gates, including a steel dam gate 1, the steel dam gate 1 is installed on the gate bottom shaft 2, the gate bottom shaft 2 is parallel to the river, and the gate bottom shaft 2 is parallel to the river channel. The shaft 2 is supported on the river channel through a plurality of steel dam gate hinges 22, and also includes: two power devices 32 and two planetary reducers 4, the power output shaft of the power device 32 is connected to the planetary reducer 4, and the planetary reducer 4 is inserted into the inner diameter of the round tube of the bottom shaft 2 of the gate, and the planetary reducer 4 is fixedly installed on the end face flange of the bottom shaft 2 of the gate through the flange plate 21, and the flange plate 21 is fixed on the end face of the bottom shaft 2 of the gate through an annular array of bolts superior. When the steel dam gate 1 is perp...

Embodiment 2

[0043] Such as Image 6As shown, the difference between embodiment 2 and embodiment 1 is that the width of the steel dam gate is 6 meters, and the height of the steel dam gate is 1 meter. A power unit 32 is arranged in the machine room 11. The reduction ratio of the planetary reducer 4 is 100. The power unit 32 is a variable frequency motor with a power of 5KW.

Embodiment 3

[0045] Such as Figure 1-Figure 5 As shown, the difference between embodiment 3 and embodiment 1 is that the width of the steel dam gate is 36 meters, the height of the steel dam gate is 2.5 meters, the reduction ratio of the planetary reducer 4 is 1000, the power unit 32 is a hydraulic motor, and the hydraulic motor The power is 30KW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com