A kind of sliding sleeve type sand blaster and using method

A technology of sand blaster and sliding sleeve, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc. It can solve the problems of improving equipment management and installation difficulty, so as to avoid oil and gas backflow from polluting the wellhead and sand particle velocity Evenly distributed and the effect of reducing the burden of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

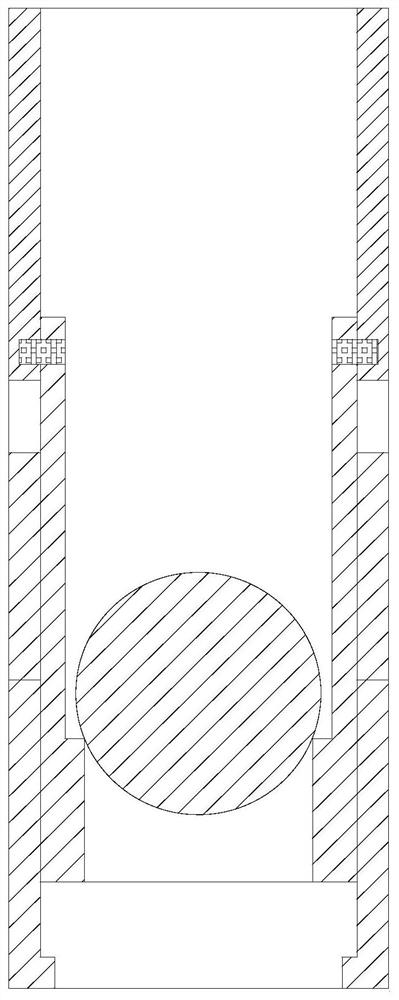

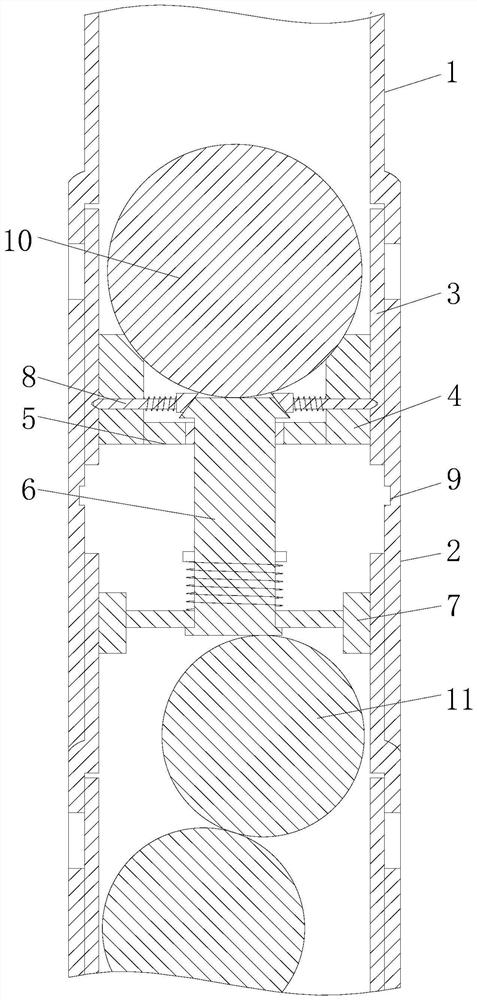

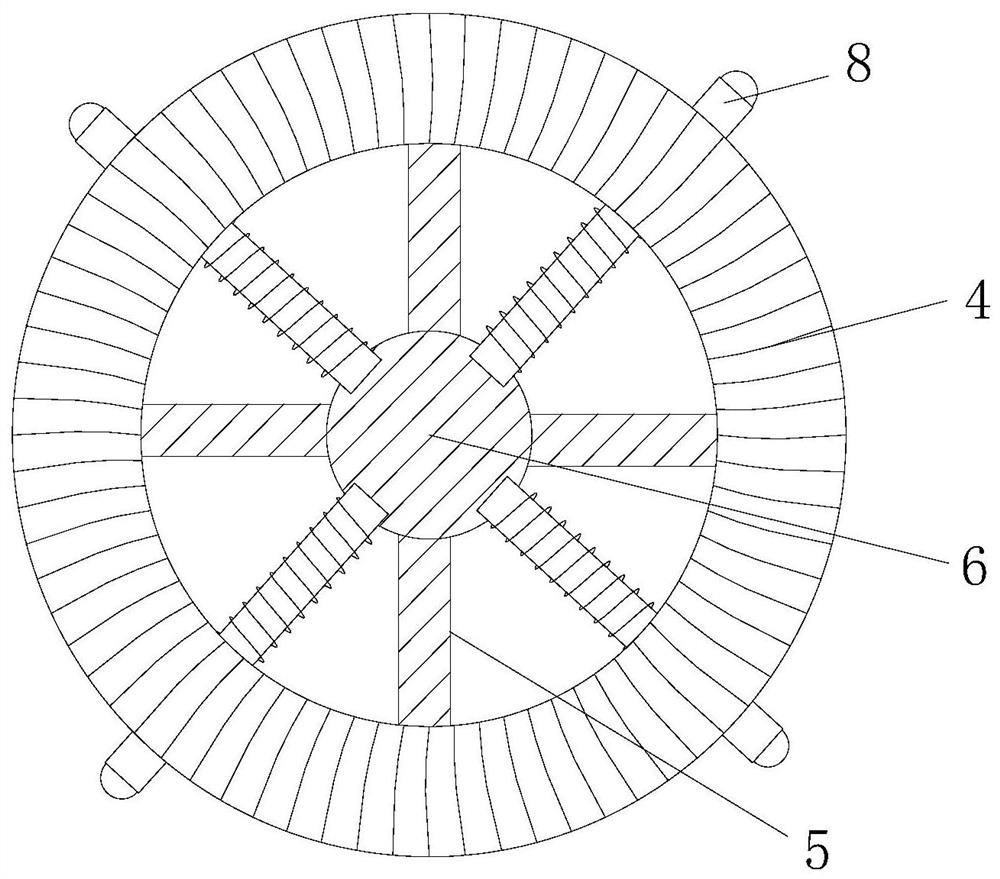

[0031] See Figure 2-5 A slip-blasting, comprising the stub 1, to take over the sleeve 2 and 3, the nozzle 4, the slider 4 slides the ball seat at a predetermined position 1 and 2 to take over the internal slide slidably provided with a ball seat corresponding sliding sleeve 3 is connected to drive the sliding sleeve 3 moves and pitching and plugging with lower pipe 10, the sliding central ball seat 4 is provided with a through hole 5, the through hole 5 to ensure that the ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com