Multifunctional butt joint device for double-pulse engine

A docking device and engine technology, applied to rocket engine devices, ramjet engines, combined engines, etc., can solve the problems of increasing labor intensity and working time, reducing production efficiency, unfavorable production costs, etc., to improve operational safety, The effect of high device utilization and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

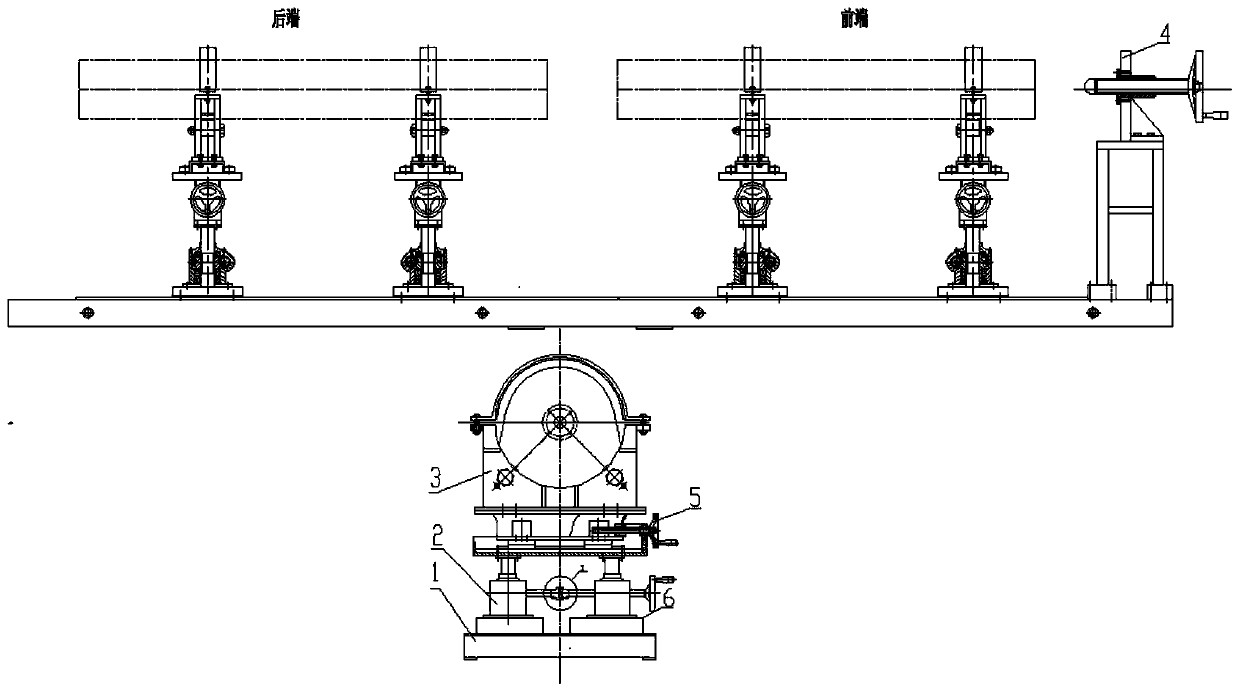

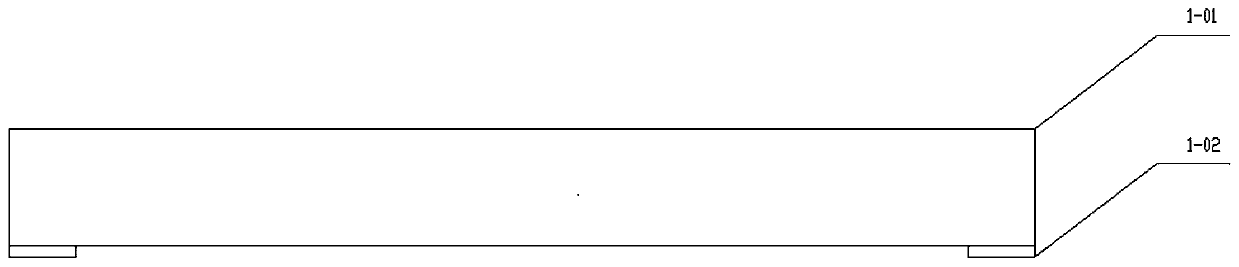

[0023] The invention provides a novel multi-functional docking device for a double-pulse engine, which is mainly composed of six parts: a lifting mechanism, a ring assembly, a pressing device, a traverse mechanism, and a supporting guide rail.

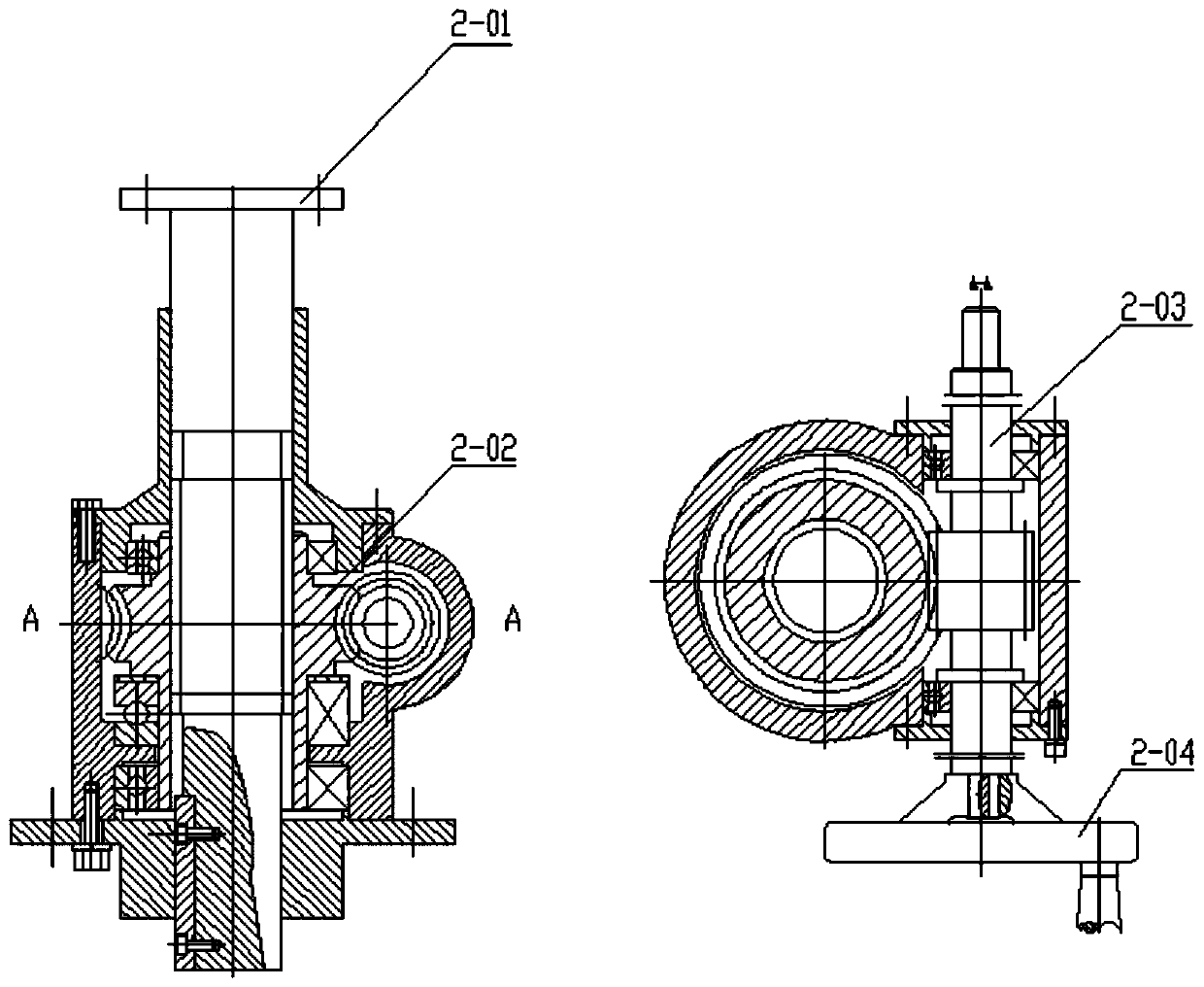

[0024] The lifting mechanism is composed of a shaft, a turbine, a worm, and a hand wheel. By shaking the hand wheel and the worm to rotate, the worm meshes to drive the turbine to realize the function of adjusting the shaft up and down;

[0025] The embracing ring assembly is composed of an upper embracing ring, a lower embracing ring and a roller. The upper embracing ring and the lower embracing ring are connected by screws. Rotation function and replacement function, convenient for engine positioning and docking and engines with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com