Shock absorbing device for electromechanical equipment

A technology of shock absorbing device and electromechanical equipment, which is applied in the direction of mechanical equipment, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of weakened shock absorption effect and inconvenient promotion and implementation, and achieve strong applicability and easy promotion and implementation , good shock absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

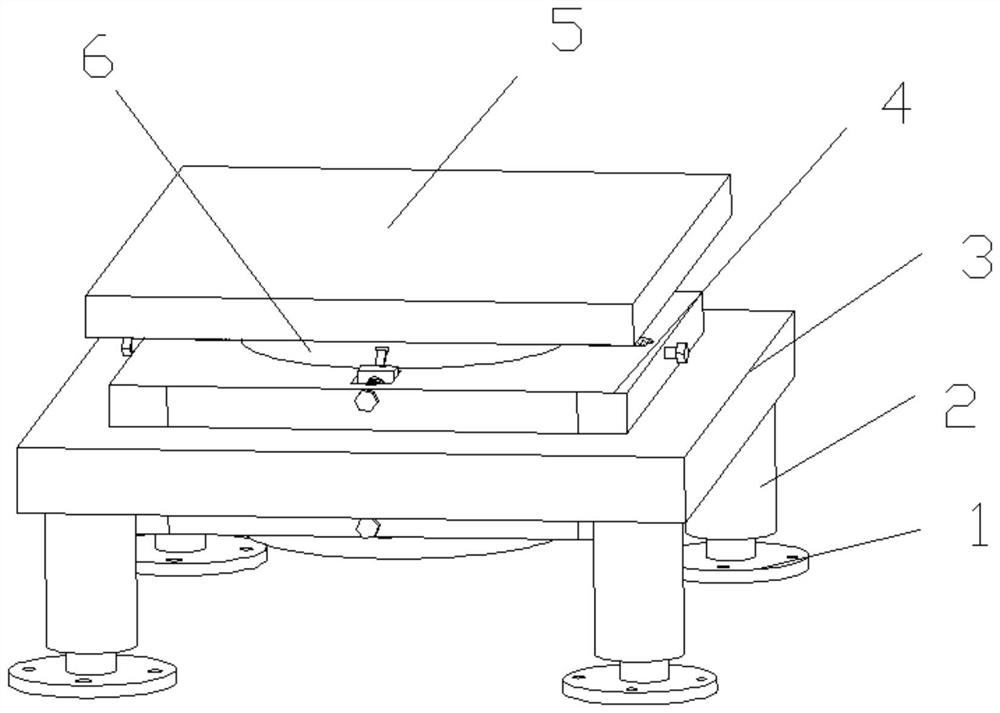

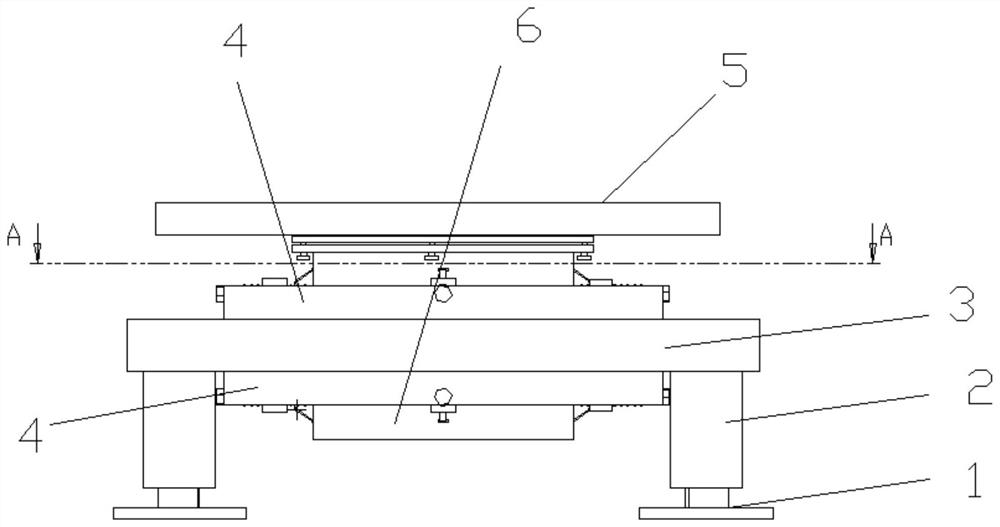

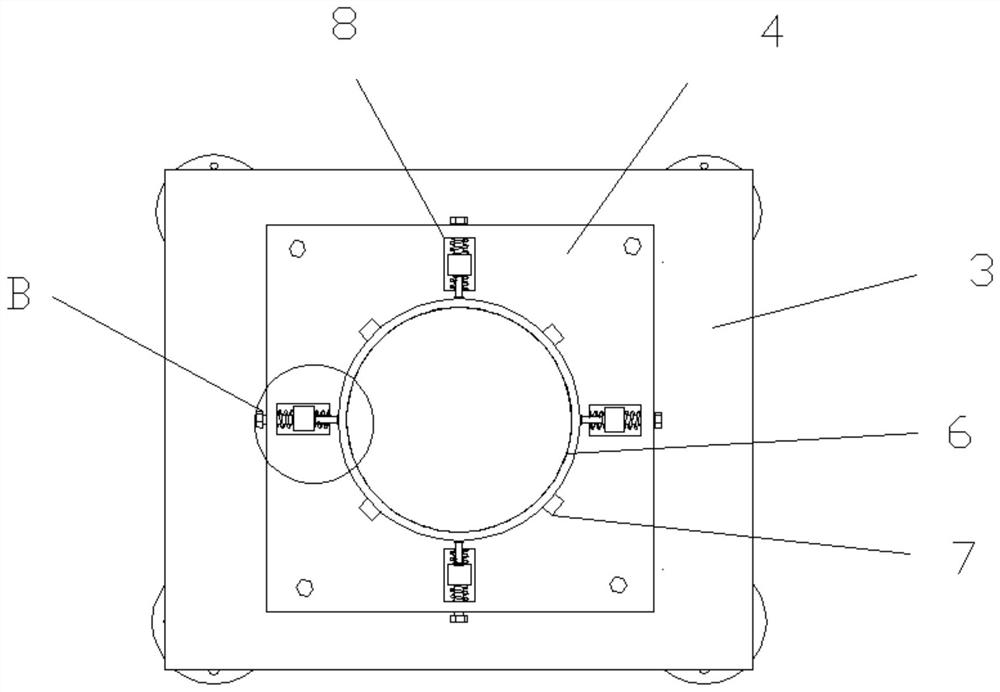

[0026] see Figure 1-4 , a shock absorbing device for electromechanical equipment, including a workbench 3 and an installation platform 5, the middle position of the workbench 3 is provided with a hollow, the upper and lower surfaces of the workbench 3 are fixedly installed with a fixing plate 4, and the center position of the lower surface of the installation platform 5 is A vertical support column 6 is fixedly connected, and the support column 6 passes through the workbench 3 and the fixed plate 4 . The support column 6 is a cylindrical structure, thereby facilitating the installation of the device. The support column 6 is a hollow structure, thereby reducing the weight of the device and saving manufacturing materials. A plurality of sliding grooves 8 are provided on the fixed plate 4, and the sliding grooves 8 are located around the support column. The sliding block 9 and the moving block 11 are slidably placed inside the sliding groove 8, and the moving block 11 is provid...

Embodiment 2

[0031] see Figure 5 , on the basis of Embodiment 1, the supporting foot 1 includes a nesting groove 17, a fixed plate 22 and a threaded rod 20, and the bottom of the supporting leg 2 includes upper and lower parts, and the upper and lower parts are detachably connected by a flange 24 , so as to facilitate the installation of the supporting foot 1. The inside of the nesting groove 17 can be nested with a second nut 19 which can be raised and lowered. The nesting groove 17 is a polygonal column structure, thereby preventing the second nut 19 from rotating inside the nesting groove 17, and the second nut 19 is nested on the threaded rod 20. Two springs 18, the second spring 18 is located below the supporting leg 2, twisting the threaded rod 20 can make the threaded rod 20 rise and fall at the bottom of the supporting leg 2, thereby adjusting the length of the threaded rod 20, thereby adjusting the compression amount of the second spring 18 to Controls the damping strength. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com