Online massecuite fluidity change detection instrument and detection method of sugar refinery

A technology of change detection and fluidity, applied in the direction of flow characteristics, instruments, scientific instruments, etc., can solve the problems of sugar removal, pseudocrystal, dissolved sugar, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

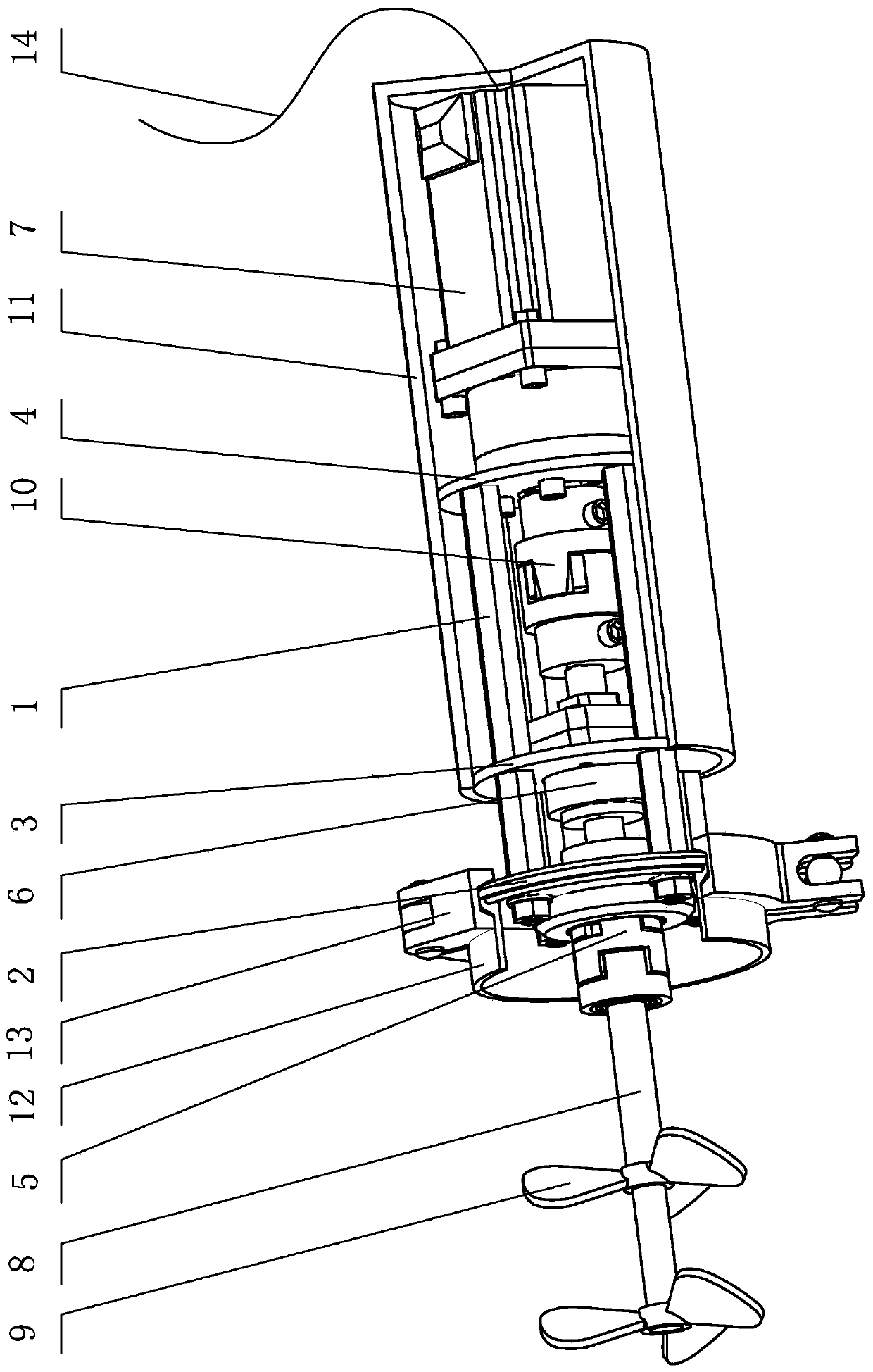

[0022] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] The on-line massecuite fluidity change detection instrument in a sugar factory of the present invention comprises a rotating shaft 8, a shaft seal mounting plate 2, a bearing mounting plate 3, a motor mounting plate 4 and a stepping motor 7 assembled together.

[0024] The shaft seal mounting plate 2 (circular plate), the bearing mounting plate 3 (circular plate), and the motor mounting plate 4 (circular plate) are coaxially arranged in front, middle, and rear order, and the shaft seal mounting plate 2 and the bearing mounting plate 3 1, the motor mounting plate 4 are fixedly installed by four support rods 1 uniformly distributed on the circumference of the respective plates, the shaft seal assembly 5 is installed in the center of the shaft seal mounting plate 2, and the bearing assembly 6 is installed in the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com