Natural gas pipeline internal corrosion rate prediction method

A technology for natural gas pipeline and internal corrosion, which is applied in prediction, instrument, calculation model, etc., can solve the problems of poor prediction accuracy of the prediction model of internal corrosion rate of natural gas pipeline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

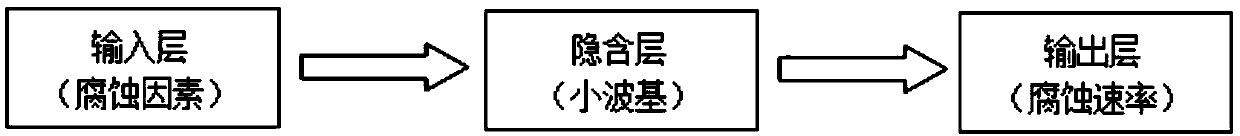

Method used

Image

Examples

Embodiment 1

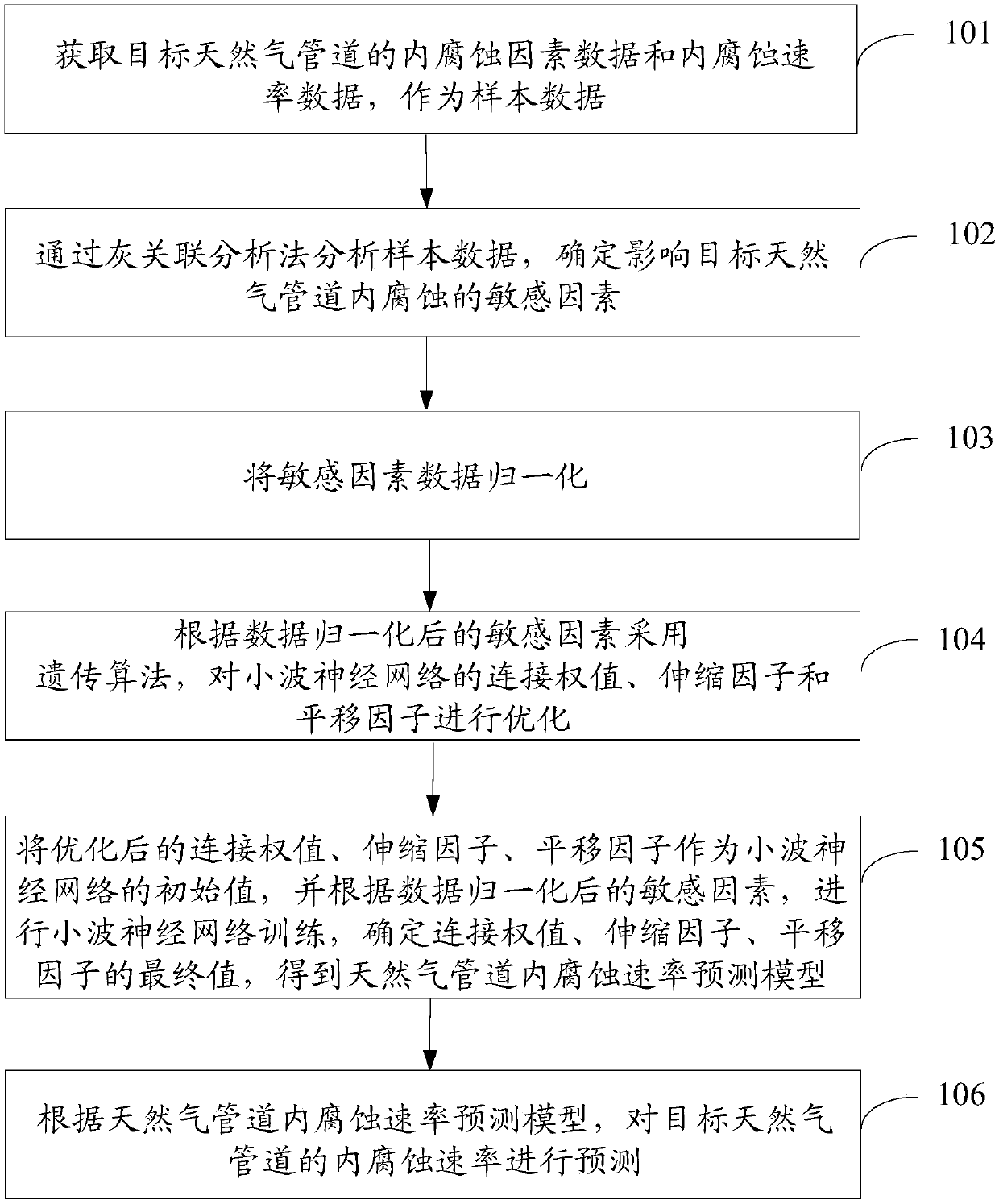

[0187] This embodiment provides a method for predicting the internal corrosion rate of a natural gas pipeline. The method uses a natural gas pipeline in a domestic gas field as a target pipeline to predict its internal corrosion rate. The target natural gas pipeline was put into operation in July 2003, the pipe material is 20G steel, the temperature is 20°C-45°C, and the corrosive medium contained is mainly CO 2 , the content is 0.55mol% ~ 0.77mol%, does not contain O 2 and H 2 S corrosive gas; CO 2 The partial pressure is between 0.0231MPa and 0.1155MPa; the pH value of the produced water is generally close to neutral; the salinity is relatively high. Specifically, the forecasting method includes:

[0188] Step 201. Obtain indoor simulated corrosion experiment data (including internal corrosion factor data and internal corrosion rate data) of the target pipeline. The data sample is shown in Table 1 below:

[0189] Table 1

[0190]

[0191]

[0192]

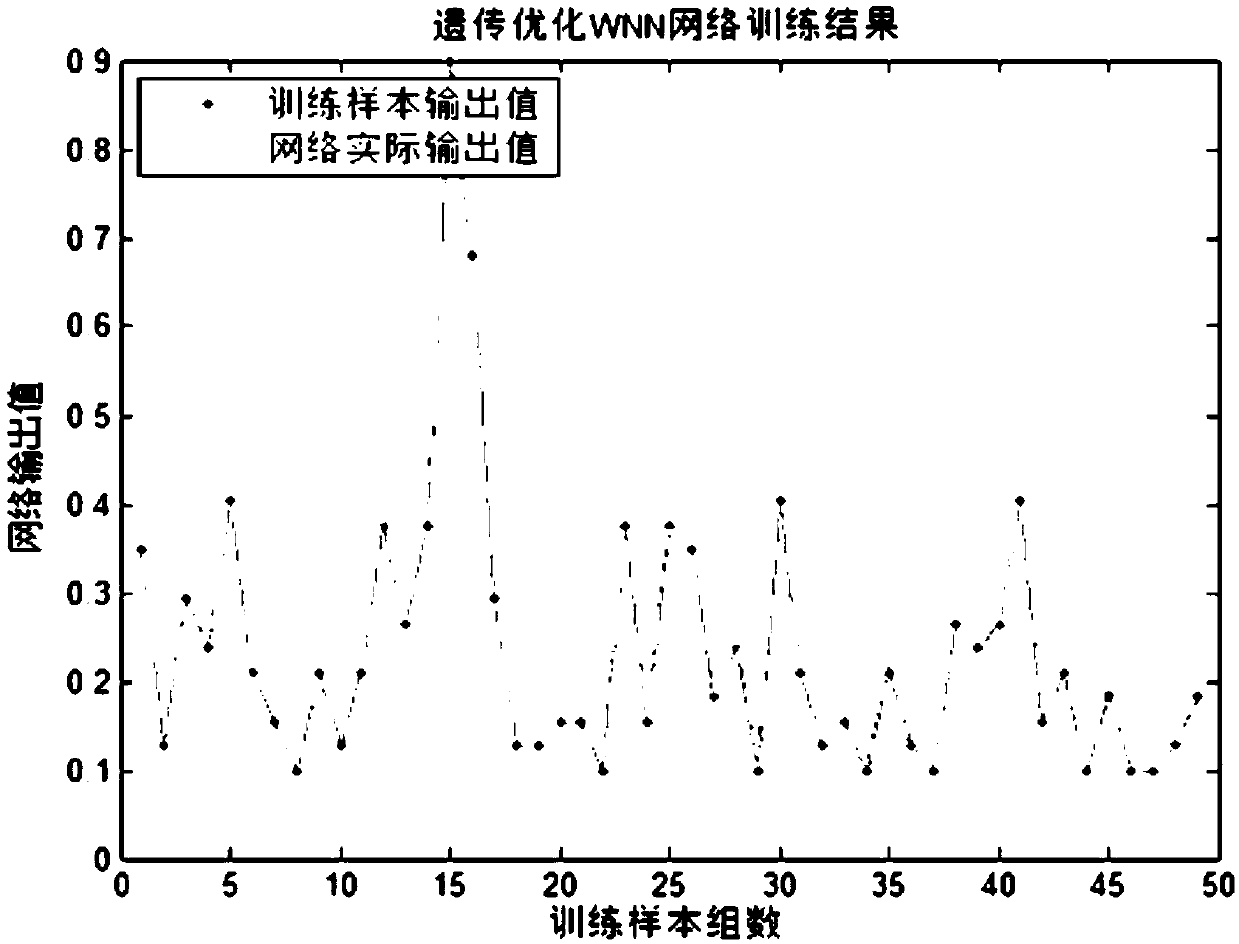

[0193] Ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap