Multifunctional sand making machine convenient to use

A sand making machine, multi-functional technology, applied in cleaning methods and utensils, removal of smoke and dust, grain processing, etc., can solve the problems affecting users' experience of using the sand making machine, poor crushing effect, etc., achieve good dust removal function, convenient movement , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

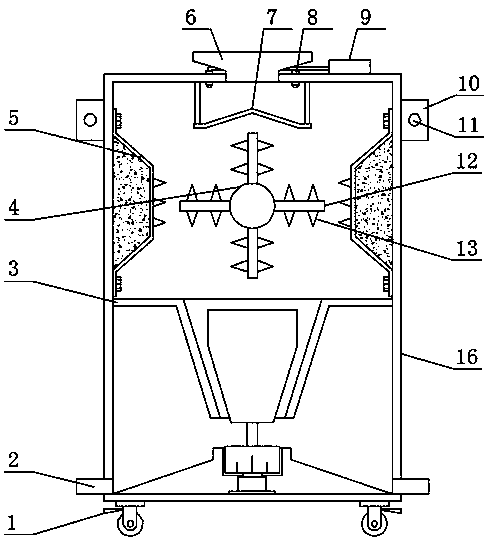

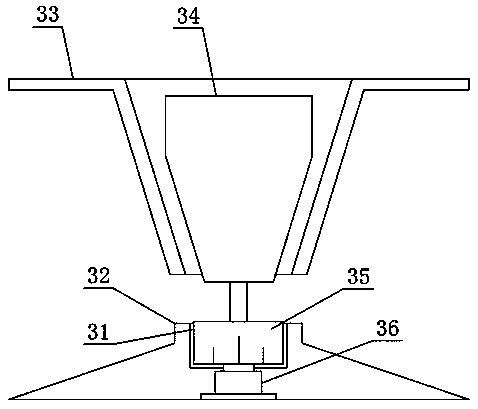

[0021] see Figure 1-Figure 4 , the present invention provides a technical solution: an easy-to-use multifunctional sand making machine, including a body 16, a feed hopper 6 is welded on the upper surface of the body 16, a discharge pipe 2 is welded on both sides of the body 16, and the body 16 The top of the rotor 4 is provided with a rotor 4. The use of the rotor 4 is an existing technology. The outer side of the rotor 4 is welded with a broken part 12. The two sides of the broken part 12 are provided with integrally formed first broken teeth 13. The inner wall of the body 16 is provided with a The crushing plate 5 corresponding to the broken piece 12, the protective plate 7 is arranged under the feeding hopper 6, the nozzle 8 is arranged on both sides of the feeding hopper 6, and the water pump corresponding to the nozzle 8 is welded on one end of the upper surface of the body 16 9;

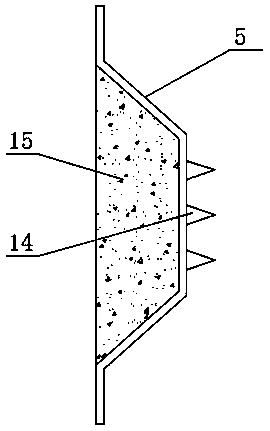

[0022] In order to enrich the functions of the crushing plate 5, in this embodiment, pref...

Embodiment 2

[0027] On the basis of Embodiment 1, in order to make the hoisting of the sand making machine more convenient, in this embodiment, preferably, the top of the body 16 is provided with a hanging plate 10, the hanging plate 10 is a cuboid structure, and the hanging plate 10 and The body 16 is fixedly connected by welding, and one end of the hanging plate 10 is provided with a hanging hole 11. When in use, the hook on the lifting equipment is passed through the hanging hole 11, and then the sand making machine is hoisted by the lifting equipment to solve the problem. The problem of inconvenient hoisting of the traditional sand making machine is solved;

[0028] In order to make the movement of the sand making machine more convenient, in this embodiment, preferably, the two ends of the lower surface of the body 16 are provided with ground wheels 1, and the ground wheels 1 are universal wheels with self-locking function. The body 16 is fixedly connected by welding, and the sand maki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com