Flat-plate settling type centrifugal machine

A settling and centrifuge technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of poor safety performance, large physical injuries to operators, complicated steps, etc., to improve safety performance and facilitate concentration. The effect of processing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

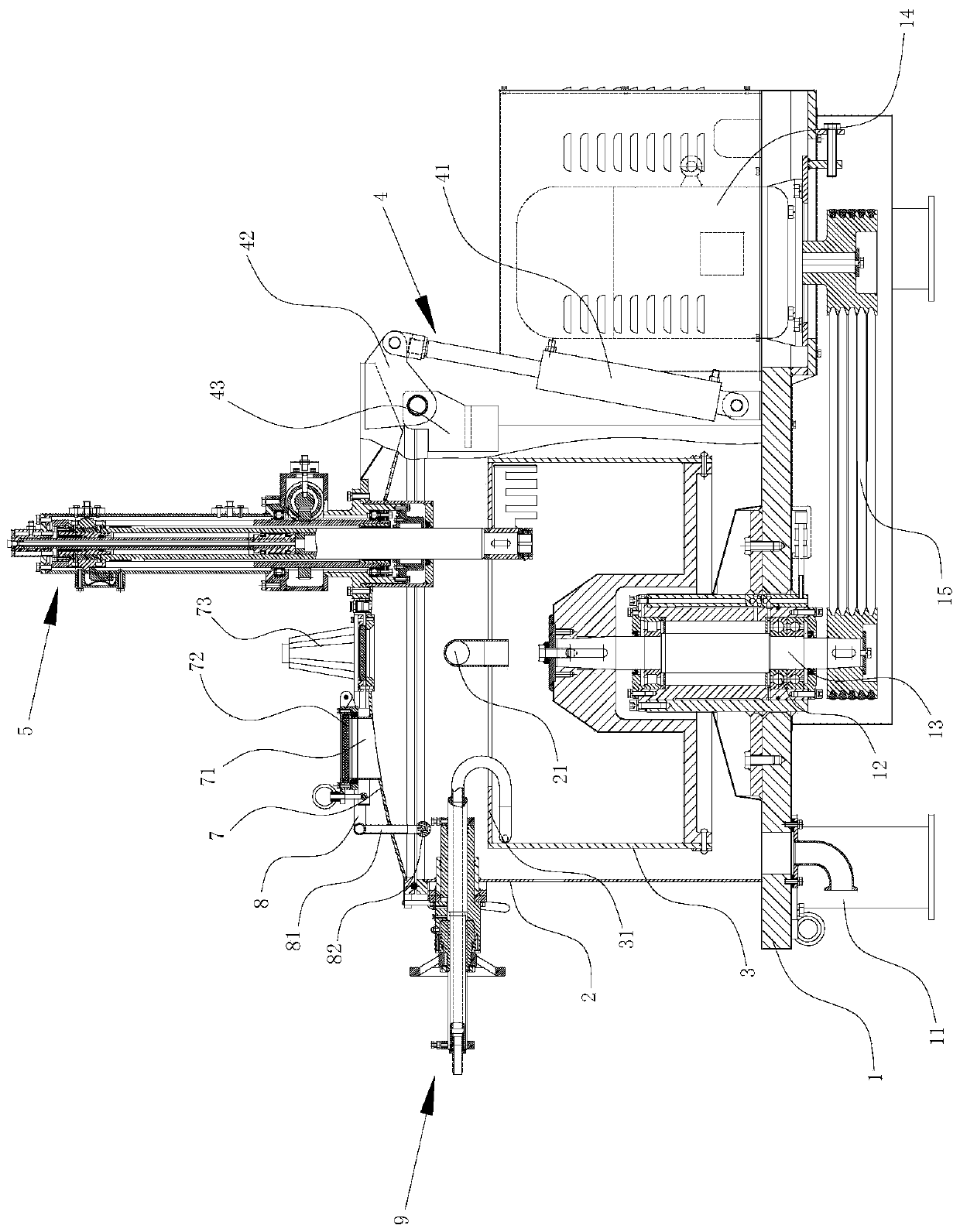

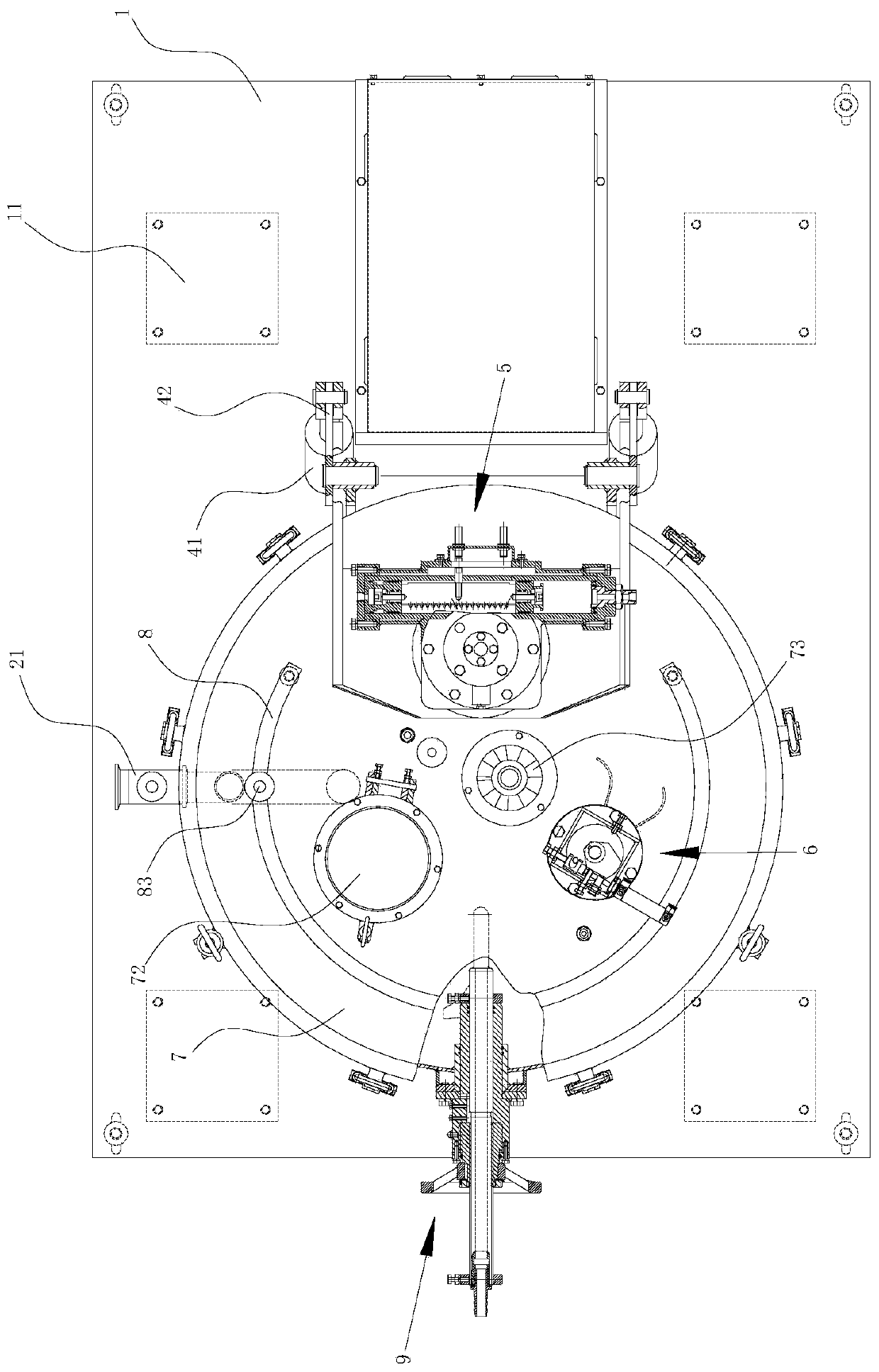

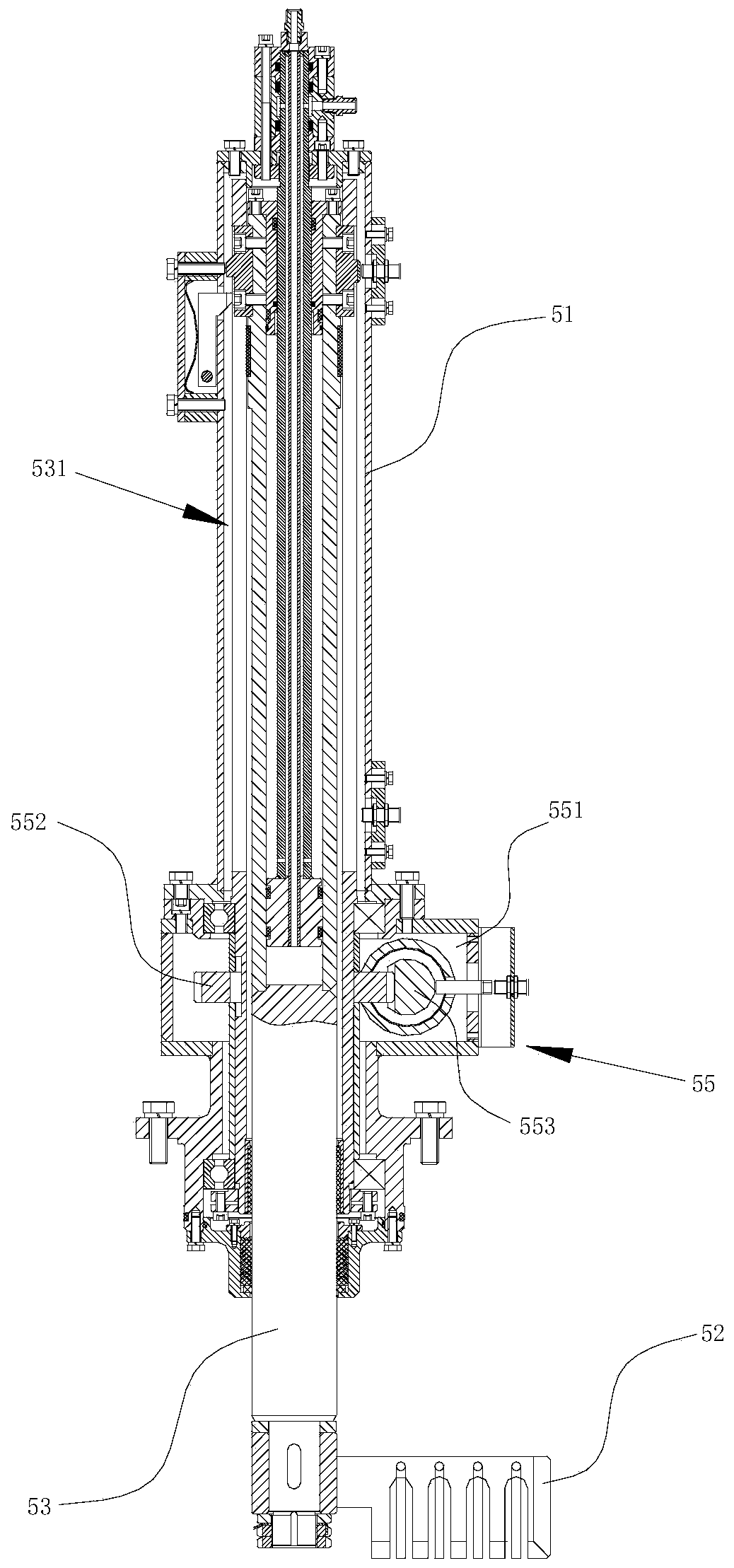

[0032] see Figure 1-Figure 7 , figure 1 and figure 2 It is only used as a schematic diagram of the overall structure of the centrifuge, and the detailed structure of the scraping mechanism, the drum, and the pumping device are as follows: Figure 3-Figure 7 prevail.

[0033] A flat decanter centrifuge, comprising a bottom plate 1, a motor 14, a drum 3, and a casing 2;

[0034] The bottom plate 1 is arranged horizontally, and several damping shock absorbers 11 are arranged on the lower side of the bottom plate 1;

[0035] The drum 3 includes the drum 3 body, which is a vertically arranged cylindrical body with an open upper side. The upper opening of the drum 3 body is provided with an annular liquid blocking plate 31 extending horizontally inward, and the bottom plate 1. A bearing 12 is provided at the upper position corresponding to the center of the drum 3, and a rotating shaft 13 is provided on the bearing 12, and the upper side of the rotating shaft 13 is coaxially c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com