Recovery treatment method and device for solid waste phenol slag produced by alkylphenol production process

A technology of alkyl phenol, recycling and processing, which is applied in the chemical industry to achieve the effects of reducing costs, simplifying the treatment process and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

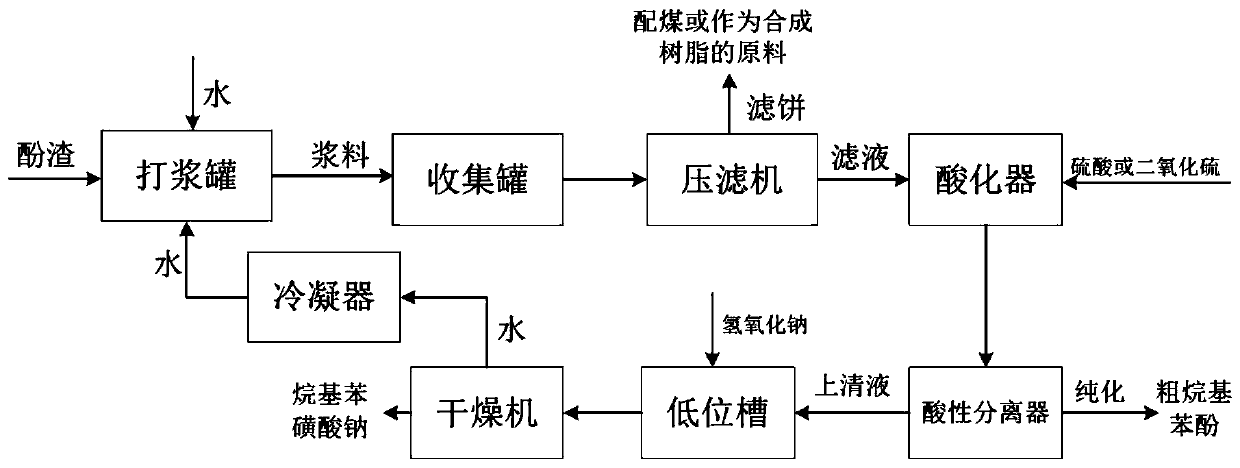

[0039] This embodiment provides a method for recycling and processing the solid waste phenol residue produced by the alkylphenol production process, such as figure 1 As shown, it includes the following steps:

[0040] (1) Put the phenol slag that has been pretreated and evaporated part of the phenol into the beating tank, and at the same time add 200g of water for every 100g of phenol slag for beating until the phenol slag is completely dispersed. After cooling down to 30°C, pump it into the slurry collection jar.

[0041] (2) After the slurry collection tank reaches 4 / 5 of the liquid level, it is pumped into the filter press for pressure filtration, and the filter cake after pressure filtration is used for coal blending or as a raw material for synthetic resin, and the filtrate enters the acidifier.

[0042] (3) Adjust the pH value to 4 by controlling the addition of sulfuric acid or sulfur dioxide, and collect a small amount of crude alkylphenol produced in the acidificati...

Embodiment 2

[0047] This embodiment provides a method for recycling and processing the solid waste phenol residue produced by the alkylphenol production process, such as figure 1 As shown, it includes the following steps:

[0048] (1) Put the phenol slag that has been pretreated and evaporated part of the phenol into the beating tank, and at the same time, add 400g of water for every 100g of phenol slag for beating until the phenol slag is completely dispersed. After cooling down to 35°C, pump it into the slurry collection jar.

[0049] (2) After the slurry collection tank reaches 4 / 5 of the liquid level, it is pumped into the filter press for pressure filtration, and the filter cake after pressure filtration is used for coal blending or as a raw material for synthetic resin, and the filtrate enters the acidifier.

[0050] (3) By controlling the addition of sulfuric acid or sulfur dioxide, the pH value is adjusted to 5, and a small amount of crude alkylphenol produced in the acidificatio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap