A lithium-ion power battery welding system

A power battery and welding system technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of battery influence, welding fixture heating, burn-through, etc., to avoid excessive pressure and accurate positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

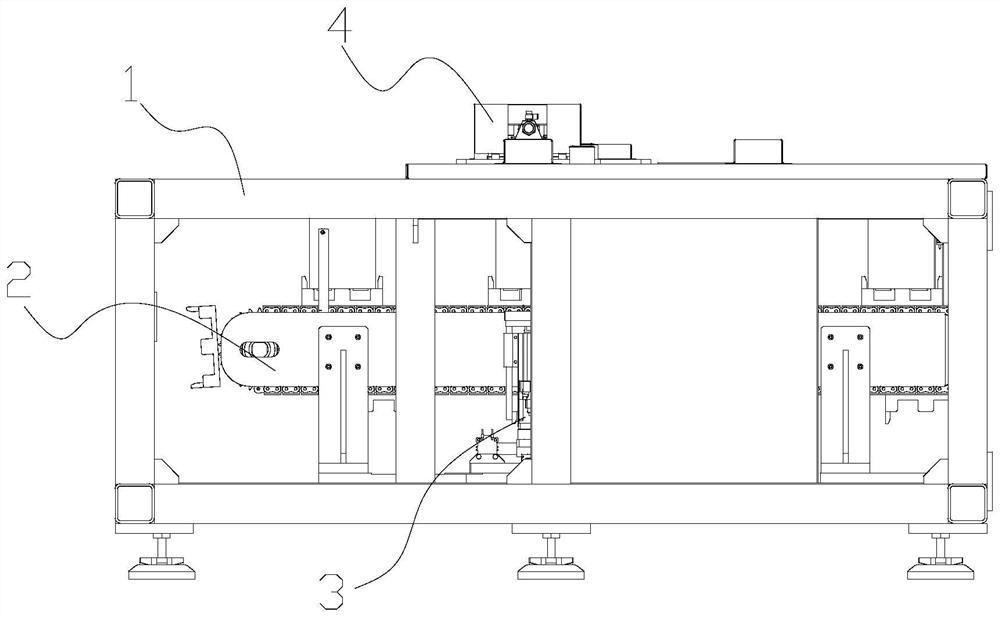

[0029] like figure 1 As shown, a lithium-ion power battery welding system includes a frame 1, a conveying line 2, a jacking mechanism 3, a welding jig 4, and a cooling device for cooling the welding jig. The frame 1 is divided into upper and lower layers, the welding fixture 4 is installed on the upper layer of the frame 1, and the conveying line 2 and the jacking mechanism 3 are installed on the lower layer of the frame 1.

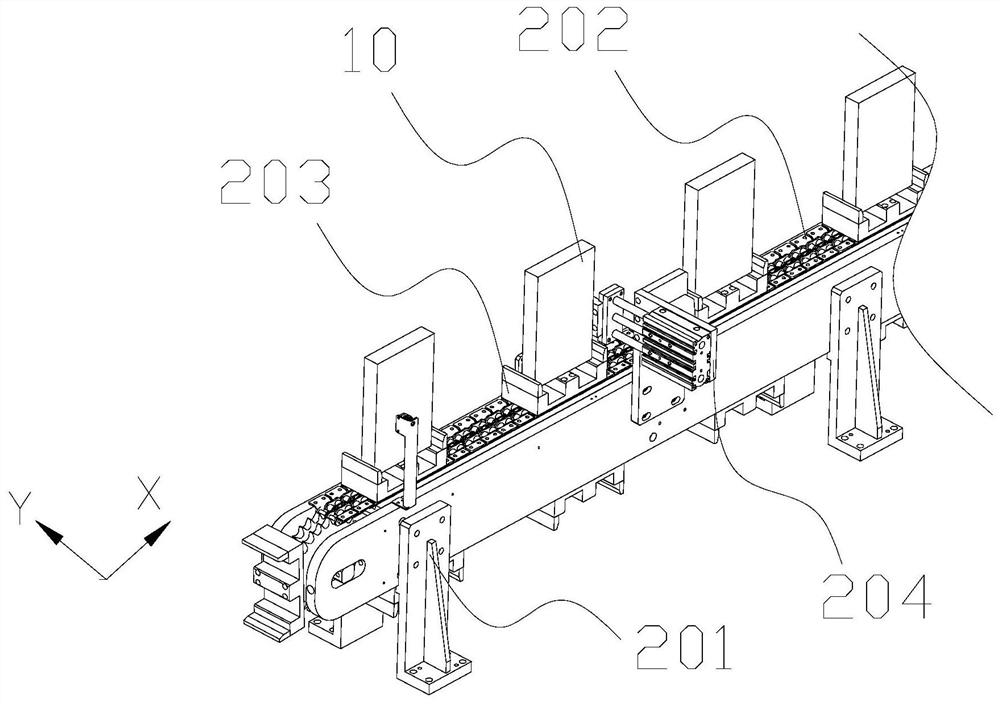

[0030] like figure 2 As shown, the transmission line 2 includes a transmission line installation bracket 201 , a transmission line actuator 202 , a battery tray 203 and an intercepting mechanism 204 . The conveyor line actuator 202 is in the form of a chain, but is not limited to this form. A plurality of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com