Aluminum-plastic separation device for waste aluminum-plated plastic

An aluminum-plastic separation and aluminum-plating technology, used in plastic recycling, smoke removal, recycling technology and other directions, can solve the problems of excessive adhesion of aluminum films, high melting point of plastics, difficult separation, etc., to increase weight, promote sufficient reaction separation, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

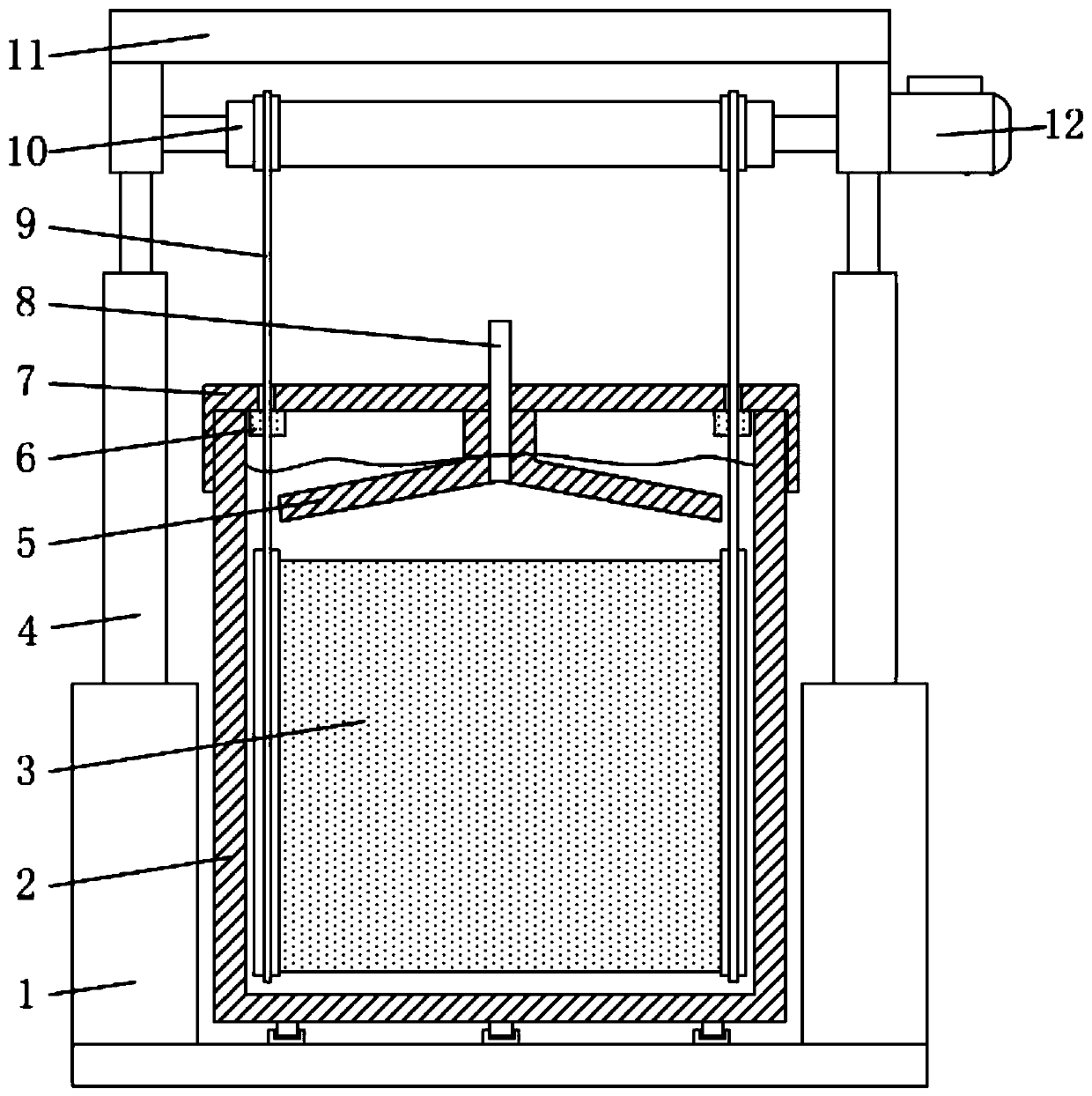

[0017] like figure 1 As shown, the aluminum-plastic separation device of waste aluminized plastics of the present invention includes a base, a solution box, a roller box, an air collecting hood, a belt, a pulley, a roller, a motor, a hydraulic cylinder and a fixed frame.

[0018] The base includes a platform and an apron, the apron is vertically fixed at both ends of the platform, and the bottom of the apron is fixedly connected with the platform. A plurality of rails are arranged in parallel on the platform, and the rails face to both sides of the platform. The height of the apron is 1 / 2 of the height of the solution tank. Guards reduce solution tank dumping.

[0019] The solution box is arranged on the platform between the guard platforms, and the solution box is a cubic box, which is made of plastic, rubber, stainless steel or a combination thereo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com