Soft tooling forming method used for reinforcing rib and web plate co-bonding and application

A forming method and technology of reinforcing ribs, which are applied in the soft tooling forming and application fields for co-bonding of reinforcing ribs and webs, can solve the problems of long manufacturing cycle, affecting the internal forming quality of parts, and lagging heating rate, etc. Achieve the effect of improving pass rate and efficiency, avoiding thermal hysteresis effect, and avoiding thickness tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment is to make soft tooling for co-gluing of stiffeners and webs, including the following steps:

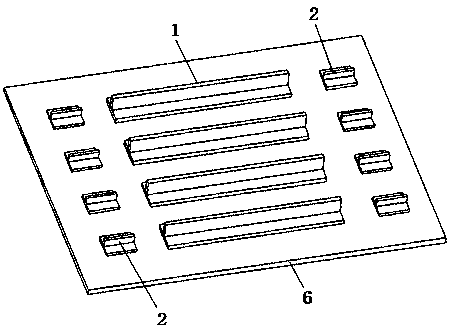

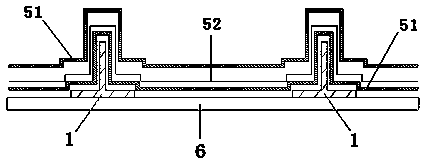

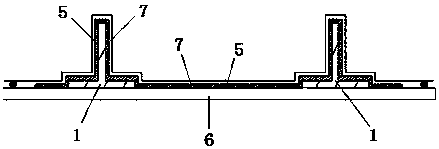

[0033] 1) Making fake parts: Since the web part of the composite material part is in a solidified state, the soft tooling is only used for the molding of the rib part of the composite material part, and ensures that after the part is formed, the rib part and the web part The relative position degree meets the design requirements. The method adopted in this embodiment is to manufacture a metal dummy 1 with a reinforcing rib that is completely consistent with the external dimensions of the reinforcing rib of the composite material part through mechanical processing. The cross section of the reinforcing rib is T-shaped or I-shaped. At the same time, the positioning device part 2 is made, and the positioning device part 2 has a positioning assembly relationship with the bottom plate 3 of the composite material part forming mold, that is, the corresponding position ...

Embodiment 2

[0039] In this example, the soft tooling made in Example 1 is used for the co-bonding of the ribs and the web, and the steps are as follows:

[0040] S1: Assembling the web: Assembling and fixing the web 8 of the composite material part in a solidified state on the mold bottom plate 3 of the composite material part. Since the web 8 is in a solidified state, positioning holes 81 can be drilled on it, and at the same time, positioning pins 32 are set on the mold base plate 3 of the composite material part, and through the cooperation of the hole pins, it is ensured that the web plate 8 is positioned on the base plate of the mold base plate of the composite material part. The position on 3 is fixed.

[0041] S2: Fill the rib prepreg: fill the pre-compacted rib prepreg 9 in the cavity formed by the stiffener metal dummy 1 on the soft tooling 5 made in embodiment 1, as Figure 4 shown.

[0042] S3: Assembling the soft tooling: the soft tooling 5 filled with rib prepreg in step S2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com