Method for achieving large-size I-beam reinforced skin structure composite workpiece co-cementing forming through soft tool

A technology of composite materials and I-beams, which is applied to household components, other household appliances, household appliances, etc., can solve problems such as inconvenient operation, high precision requirements for mold processing, skin part thickness and non-destructive testing tolerance, etc., to achieve Improve pass rate and efficiency, avoid thermal hysteresis effect, and avoid the effect of out-of-tolerance profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further description will be made below in conjunction with specific embodiments and accompanying drawings.

[0026] The detailed flow of the soft tooling to realize the co-bonding of I-beam reinforced skin structure composite parts is as follows:

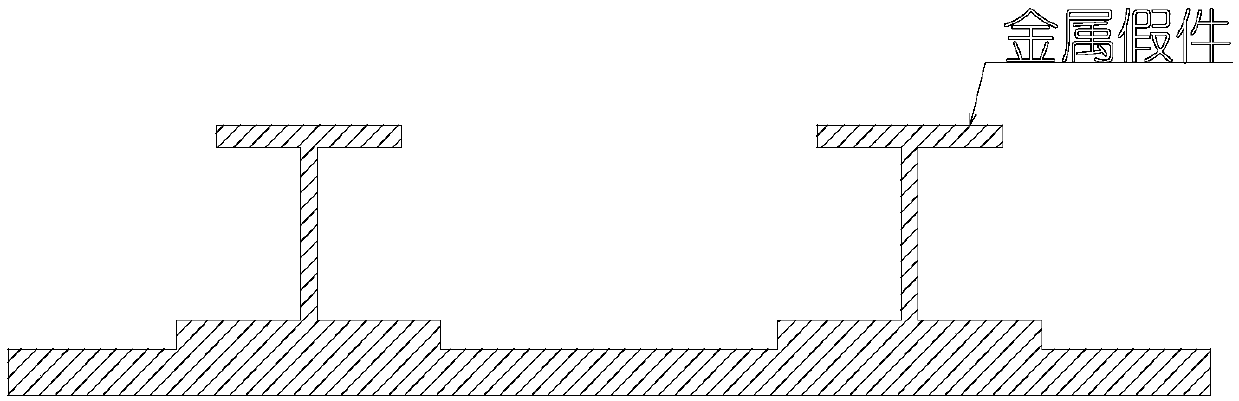

[0027] 1. Through the method of mechanical manufacturing, process a metal dummy that is exactly the same in size as the reinforced skin of the I-beam (such as figure 1 ), as a molding die for soft tooling;

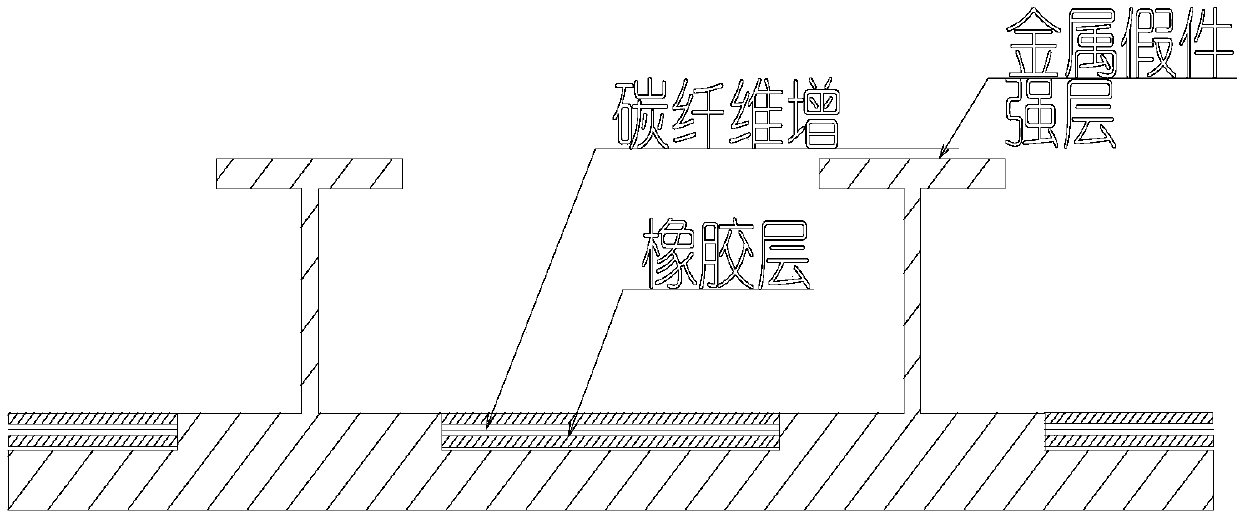

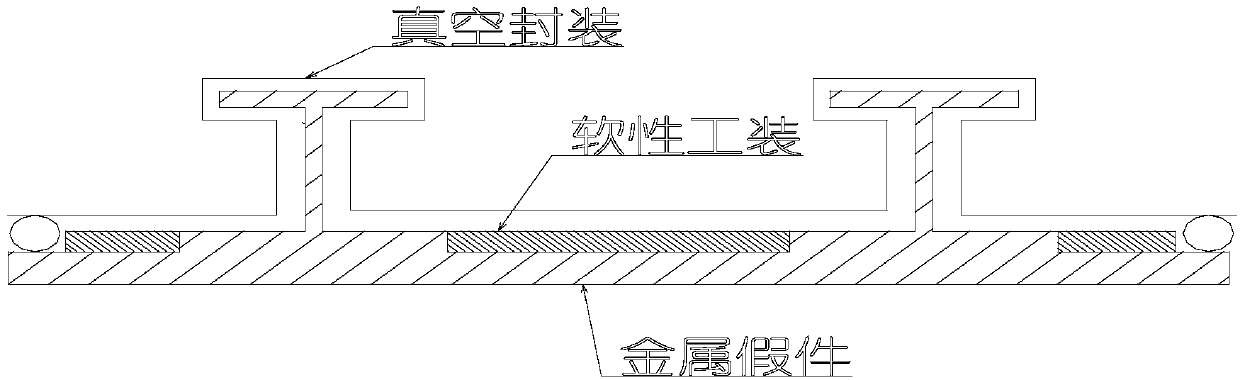

[0028] 2. Lay soft tooling in the cavity formed between the I-beams on the metal dummy (such as figure 2 ). The soft tooling uses rubber as the main material, and the rubber is laid layer by layer in the cavity, and carbon fiber prepreg is laid in the middle of the rubber layer as a reinforcement layer to improve the overall rigidity of the soft tooling. The number of layers of material mainly depends on the size and structural complexity of composite parts. Finally seal the vacuum bag (such as image 3 ), and accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com