A ternary material power lithium battery explosion-proof sheet aluminum material and its preparation method

A technology of ternary materials and lithium batteries, applied in manufacturing tools, metal rolling, heat treatment equipment, etc., can solve the problems of 1060 alloy large grains, large fluctuations in mechanical elongation, unstable blasting values, etc., and achieve grain size Uniformity, uniform structure and mechanical properties, and the effect of improving poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

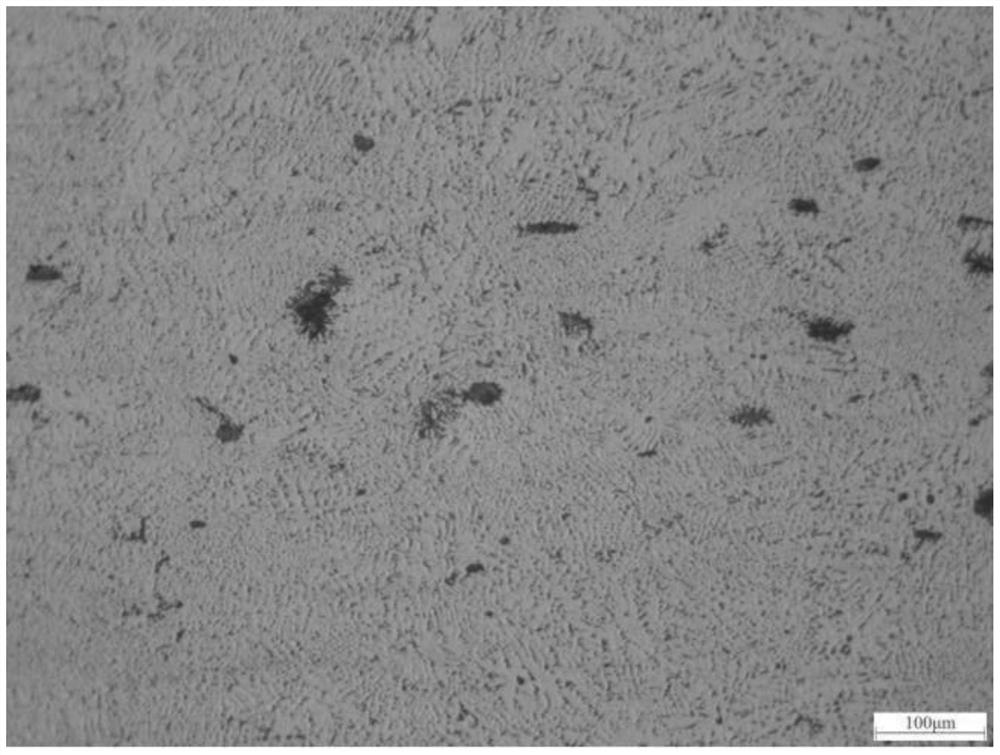

Embodiment 1

[0035] A method for preparing a ternary material power lithium battery explosion-proof sheet aluminum material, comprising the following steps:

[0036] (1) Casting billet composition control: add 0.2% iron by mass percentage, 0.04% silicon by mass percentage and 0.04% manganese by mass percentage according to the iron-silicon ratio of 5.0 and the manganese-silicon ratio of 1.0, and then add the weight The percentage is 0.015% titanium, and the balance is aluminum to obtain the chemical composition of the aluminum material of the ternary material power lithium battery explosion-proof sheet.

[0037] (2) Process treatment of casting and rolling coils: Add the chemical components in the proportion in step 1 into the melting furnace, melt at a temperature of 735°C, and process the melt through online stirring and feeding slagging agents and refining agents to obtain qualified melts. body weight, enter the degassing device to eliminate the hydrogen existing in the melt, in the cas...

Embodiment 2

[0044] A method for preparing a ternary material power lithium battery explosion-proof sheet aluminum material, comprising the following steps:

[0045] (1) Casting billet composition control: add 0.3% iron by mass percentage, 0.06% silicon by mass percentage and 0.06% manganese by mass percentage according to the iron-silicon ratio of 5.0 and the manganese-silicon ratio of 1.0, and then add the weight The percentage is 0.008% titanium, and the balance is aluminum to obtain the chemical composition of the aluminum material of the ternary material power lithium battery explosion-proof sheet.

[0046] (2) Process treatment of casting and rolling coils: Add the chemical components in the proportion in step 1 into the melting furnace, melt at a temperature of 745°C, and process the melt through online stirring and feeding slagging agents and refining agents to obtain qualified melts. In the casting and rolling area, the temperature drop from the aluminum liquid to the aluminum pla...

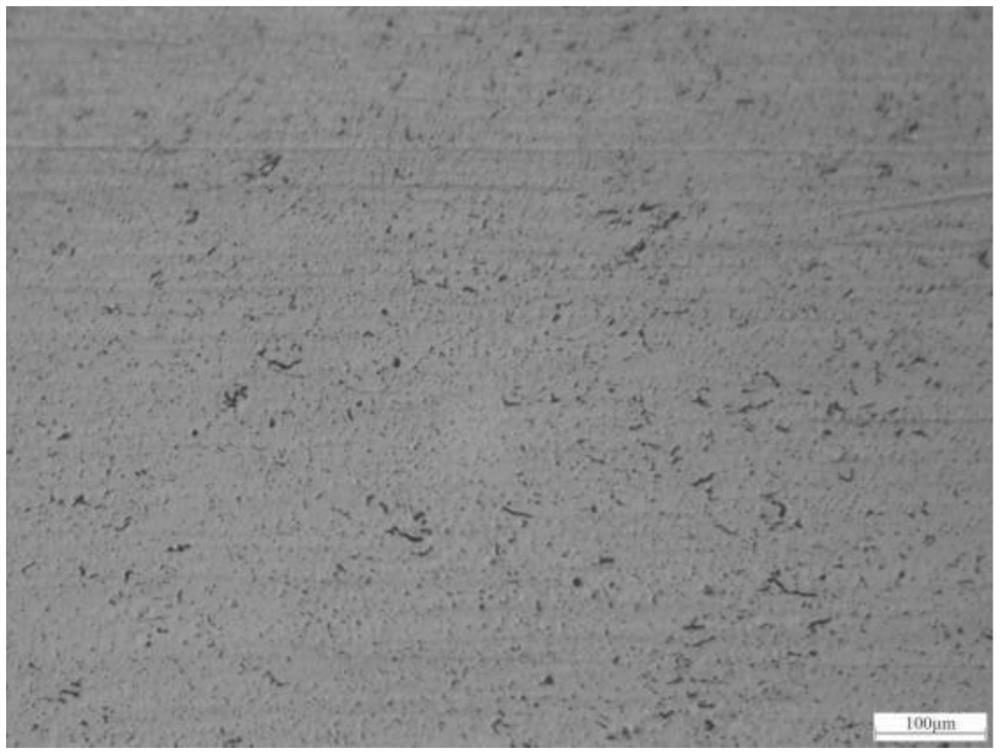

Embodiment 3

[0053] A method for preparing a ternary material power lithium battery explosion-proof sheet aluminum material, comprising the following steps:

[0054] (1) Casting billet composition control: add 0.25% iron by mass percentage, 0.05% silicon by mass percentage and 0.05% manganese by mass percentage according to the iron-silicon ratio of 5.0 and the manganese-silicon ratio of 1.0, and then add the weight The percentage is 0.011% titanium, and the balance is aluminum to obtain the chemical composition of the aluminum material of the ternary material power lithium battery explosion-proof sheet.

[0055] (2) Process treatment of casting and rolling coils: Add the chemical components in the proportion in step 1 into the melting furnace, melt at a temperature of 740°C, and process the melt through online stirring and feeding slagging agents and refining agents to obtain qualified melts. body weight, enter the degassing device to eliminate the hydrogen present in the melt, in the cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com