Manufacturing method and application of soft tool for longitudinal-transverse T-shaped reinforcing rib part forming

A manufacturing method and a technology of reinforcing ribs, which are applied in the production and application field of soft tooling for forming vertical and horizontal T-shaped reinforcing ribs, can solve the problems of high manufacturing and maintenance costs of metal core molds, affecting the internal molding quality of parts, and the manufacturing problems. Problems such as the thickness of T-shaped ribs are out of tolerance, so as to improve the pass rate and efficiency, avoid the effect of thermal hysteresis, and avoid the effect of thickness out of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment is a soft tooling manufacturing method for forming vertical and horizontal T-shaped rib parts, including the following steps:

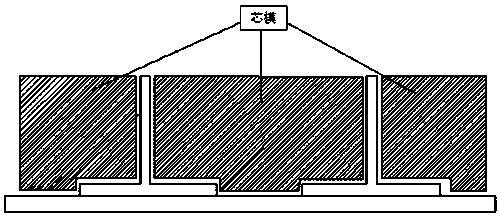

[0040] 1) Making a metal dummy: a metal dummy 1 that is exactly the same in shape and size as the composite material part 10 with vertical and horizontal T-shaped ribs is manufactured by a mechanical manufacturing method.

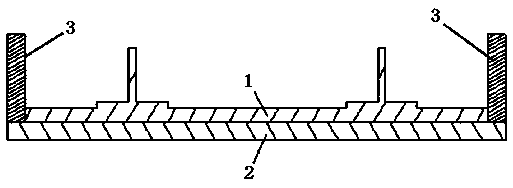

[0041] 2) Dummy assembly: assemble the metal dummy 1 produced in step 1 on the mold bottom plate 2 for molding the composite material part 10 according to the molding requirements of the composite material part 10, and set up barriers around the mold bottom plate 2 Plate 3, the baffle 3 is a part of the forming mold, and at the same time acts as a limiter for the metal dummy 1, such as figure 2 shown.

[0042] 3) Paving materials for making soft tooling: In step 2, the surface of the cavity formed between the metal dummy 1 and the baffle 3 is paved with material 5 for making soft tooling. The material 5 for...

Embodiment 2

[0045] This embodiment is an application of the soft tooling made according to the method of Embodiment 1, including the following steps:

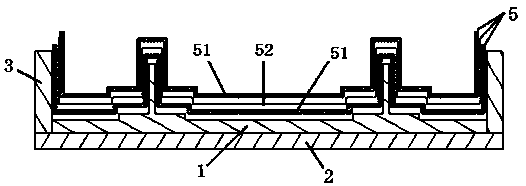

[0046] S1: Making the supporting structure of the soft tooling: laying 3 to 5 layers of carbon fiber prepreg layers on the outer surface of the soft tooling 4 manufactured according to the method described in Example 1 and then curing by hot pressing, the process parameters of hot pressing The curing pressure is 500-800kPa, the curing temperature is 160-200°C, and the curing time is 120-200min. , to form a composite material protective shell 6; then pour polyurethane foam 7 into the cavity formed by the composite material protective shell 6, and after the polyurethane foam 7 is solidified, it forms a soft shell with the composite material protective shell 6 Support structure for tooling 4, such as Figure 5 shown.

[0047] S2: Fill the prepreg part of the T-shaped rib: take out the soft tooling 4 and its supporting structure in step S1 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com