Manufacturing method for soft mode for I-beam composite material piece forming and application thereof

A technology of composite materials and manufacturing methods, which is applied to the production of soft molds for forming I-beam composite parts and its application fields, which can solve the problems of low manufacturing success rate, irreparable repair, and long manufacturing cycle, and achieve guaranteed surface and dimensional accuracy, easy post-maintenance, and improved pass rate and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The present embodiment provides a method for making a soft mold for forming an I-beam composite material part, comprising the following steps:

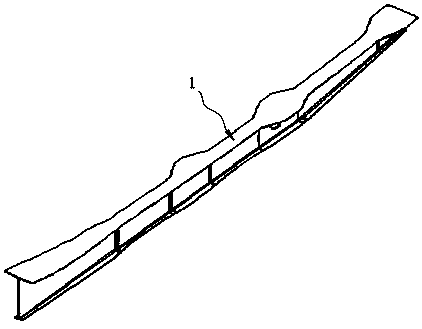

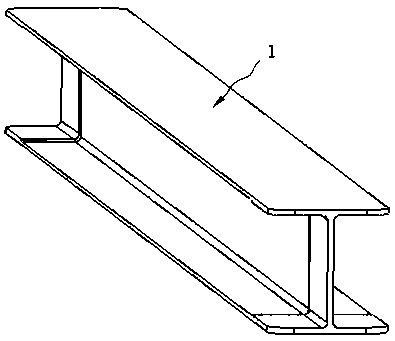

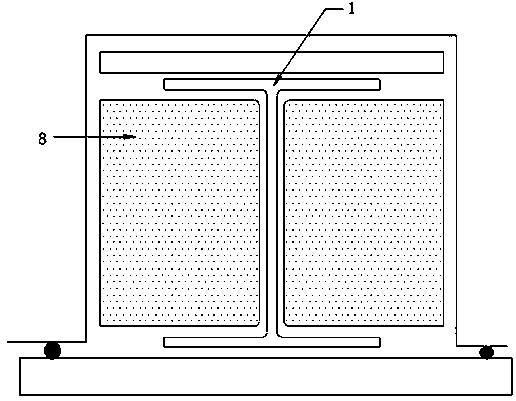

[0036] 1) Making dummy parts and molds: Process a set of I-beam metal dummy parts 2 that are exactly the same in size as the I-beam composite material part 1 by means of mechanical manufacturing, and at the same time make a set of soft molds for making soft molds Forming mold 3, the soft mold forming mold 3 includes an upper template 31 and a lower template 32, and the corresponding inner surfaces of the upper template 31 and the lower template 32 are all provided with cards matching the upper and lower sides of the I-beam metal dummy 2 Groove 4, so as to play a role of cooperation and limit during assembly, such as Figure 5 shown.

[0037] 2) Assembling and laying materials: Assemble the metal dummy part and the soft molding mold made in step 1) together according to the matching relationship, the two sides of the I-beam met...

Embodiment 2

[0041] This embodiment provides a method for using a soft mold for forming an I-beam composite material part. The soft mold 5 made according to the method described in Embodiment 1 is used as a part of the forming mold for the I-beam composite material part 1, and is matched with the The soft mold forming mold 3 that is made completes the manufacturing process of manufacturing the I-beam composite material part 1, such as Figure 8 shown. The specific process is as follows:

[0042] First, two sets of preformed tooling are made, and the U-shaped components on both sides of the I-beam composite product are laid on the preformed tooling. After the paving is completed, the U-shaped component is peeled off from the preformed tooling and laid on Example 1. On the soft mold 5 used for forming the I-beam composite parts made in the above. While paving the U-shaped assembly, pave the top plate of the I-beam composite material part in the slot 4 of the upper template 31 of the soft m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com