Three-layer composite self-lubricating material and continuous production process thereof

A self-lubricating material and production process technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve problems such as contamination of the heating plate, and achieve the effect of solving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

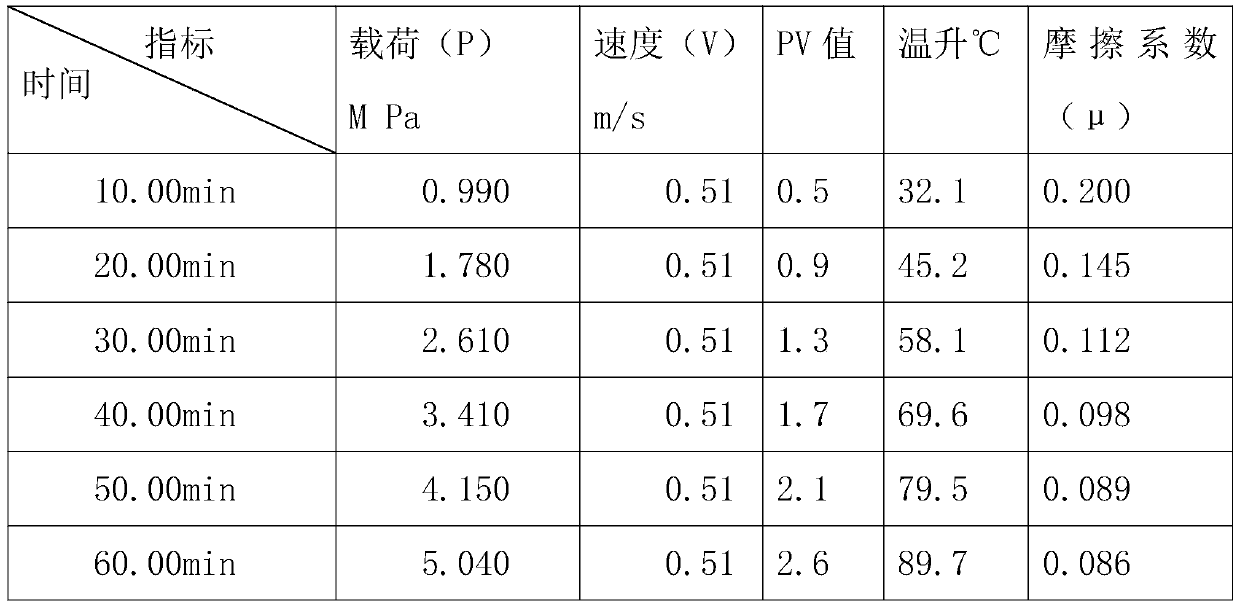

Examples

Embodiment Construction

[0033] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0034] A three-layer composite self-lubricating material, including a metal substrate layer, a ball powder layer and a PEEK modified material layer on the ball powder layer; the metal substrate layer is one of iron-based, iron-copper sintered and copper-based One, the ball powder layer is sintered on the substrate, and the PEEK modified material layer is compounded on the surface of the ball powder layer by hot rolling; the PEEK modified material layer is composed of raw materials with the following weight components:

[0035] MoS2: 0.5-15%;

[0036] Fiber: 1-20%;

[0037] ZnS: 0-12%;

[0038] TiO2: 0.2-12%;

[0039] Graphite: 0.5-10%;

[0040] Zirconium phosphate: 0-10%;

[0041] Alumina: 0-10%;

[0042] PEEK resin: balance.

[0043] The fiber is one of carbon fiber (i.e. C-fiber) or glass fiber; the spherical SiO 2 The average particle di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com