Suspension train car end connection method and system

A connection system and vehicle-end technology, which is applied to elevated railway systems, motor vehicles, and railway vehicles with suspended vehicles, can solve problems such as poor stability of suspended train passages, meet dynamic performance, and improve comfort , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

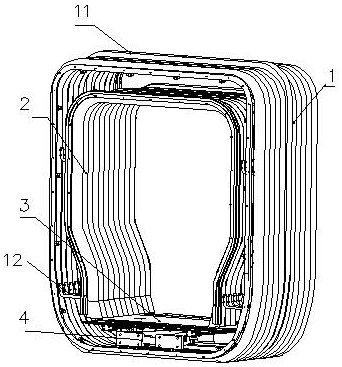

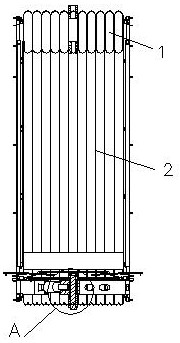

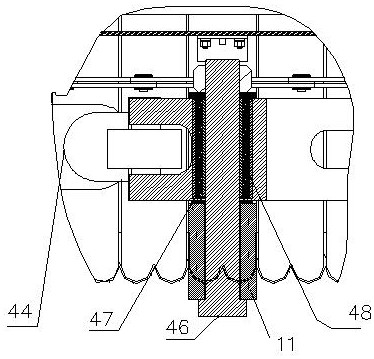

[0036] like Figure 1-Figure 9 As shown, a suspension train car end connection system includes an outer bellows 1, an inner bellows 2, a floor composition 3 and a hinge device 4, the inner bellows 2 is a "Ji"-shaped structure with an opening at the lower end, and the outer bellows 1 The middle frame 11 is provided to fix and support the entire outer bellows 1 to prevent the outer bellows 1 from sagging; Both ends of the bellows 1 and the inner bellows 2 are fixedly connected to the ends of the two adjacent compartments, the outer bellows 1 and the inner bellows 2 are connected by fixed rods 12, the middle frame 11 and the middle inner frame 21 It is also connected by the fixed rod 12. In this embodiment, the upper and lower parts of the inner bellows 2 and the outer bellows 1 are connected by the fixed rods 12 to ensure the consistency of the positions between the outer bellows 1 and the inner bellows 2 . Of course, the position of the fixing rod 12 can also be set according...

Embodiment 2

[0041] In this embodiment, for the vehicle type with a coupler on the top of the vehicle body, the top of the middle frame 11 can also be fixed to the vehicle body through the coupler, that is, the middle frame 11 is fixed to the vehicle body through the upper and lower positions to further ensure the stability of the passageway sex.

[0042] It can be seen from the above embodiments that the present invention also relates to a method for connecting the ends of suspended trains. The outer bellows 1 is divided into two parts by the middle frame 11, and the inner bellows 2 is also divided into two parts by the middle inner frame 21, so that the inner bellows 2 can be divided into two parts. Extend the length of the bellows without causing the bellows to sag due to gravity, and ensure that the suspended vehicles can smoothly realize the small-radius curve movement without interference. A hinged device 4 with a vibration-damping structure is arranged below the floor composition 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com