Fenton reactor

A reactor, Fenton's technology, applied in chemical instruments and methods, oxidation treatment of sludge, water/sewage treatment, etc., can solve the problems of difficult dosing and mixing, unstable water treatment effect, and long reaction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

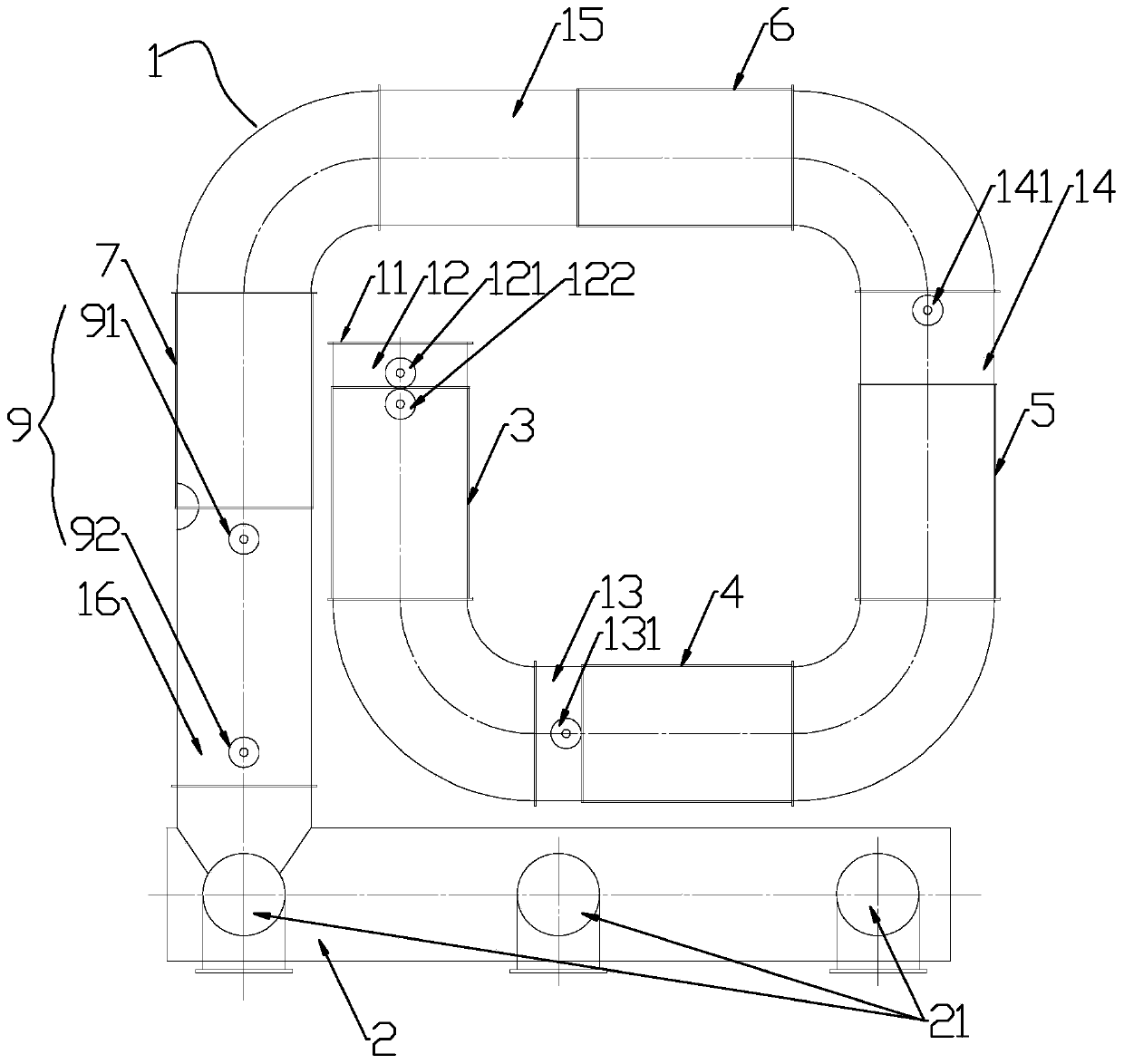

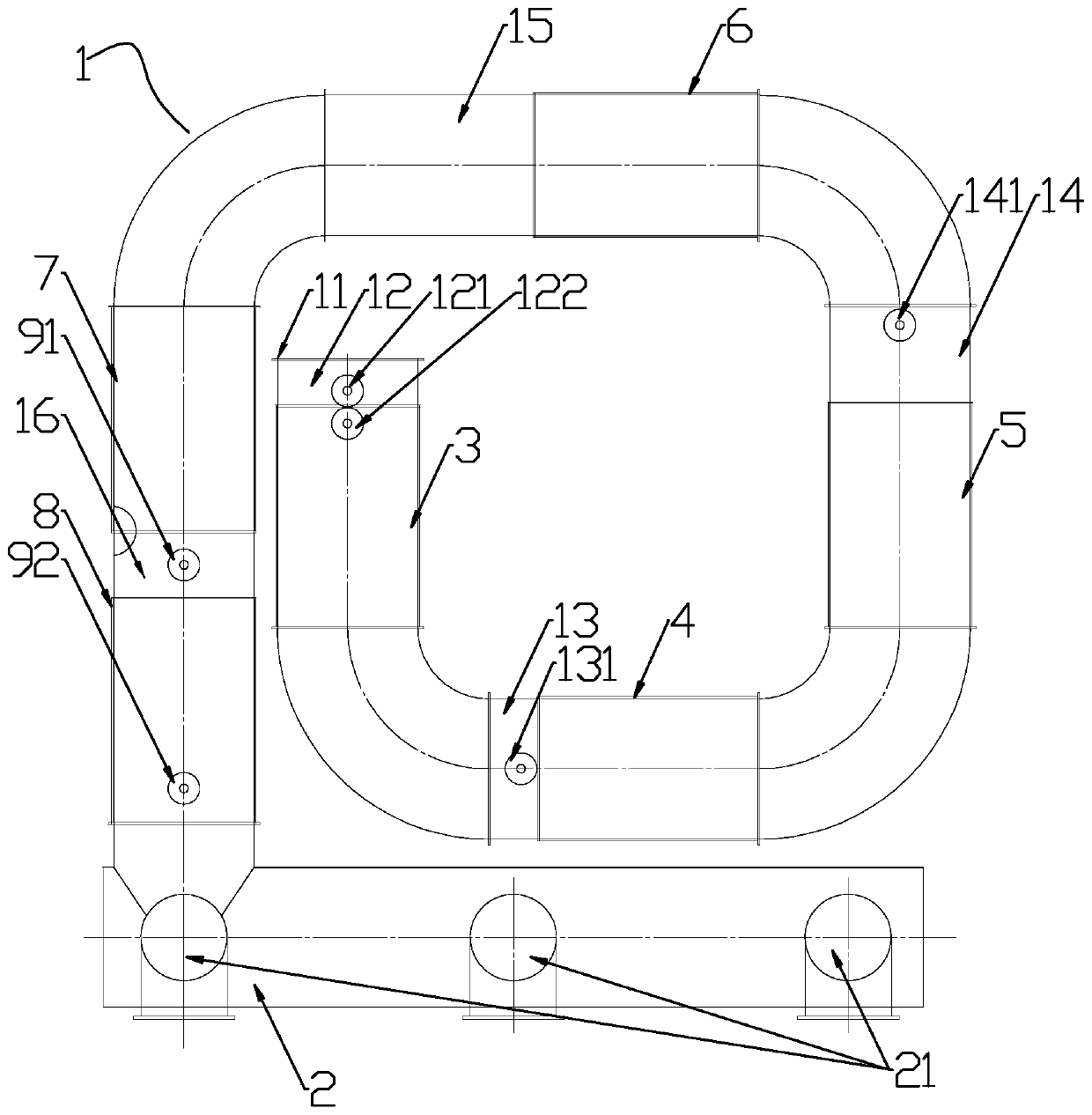

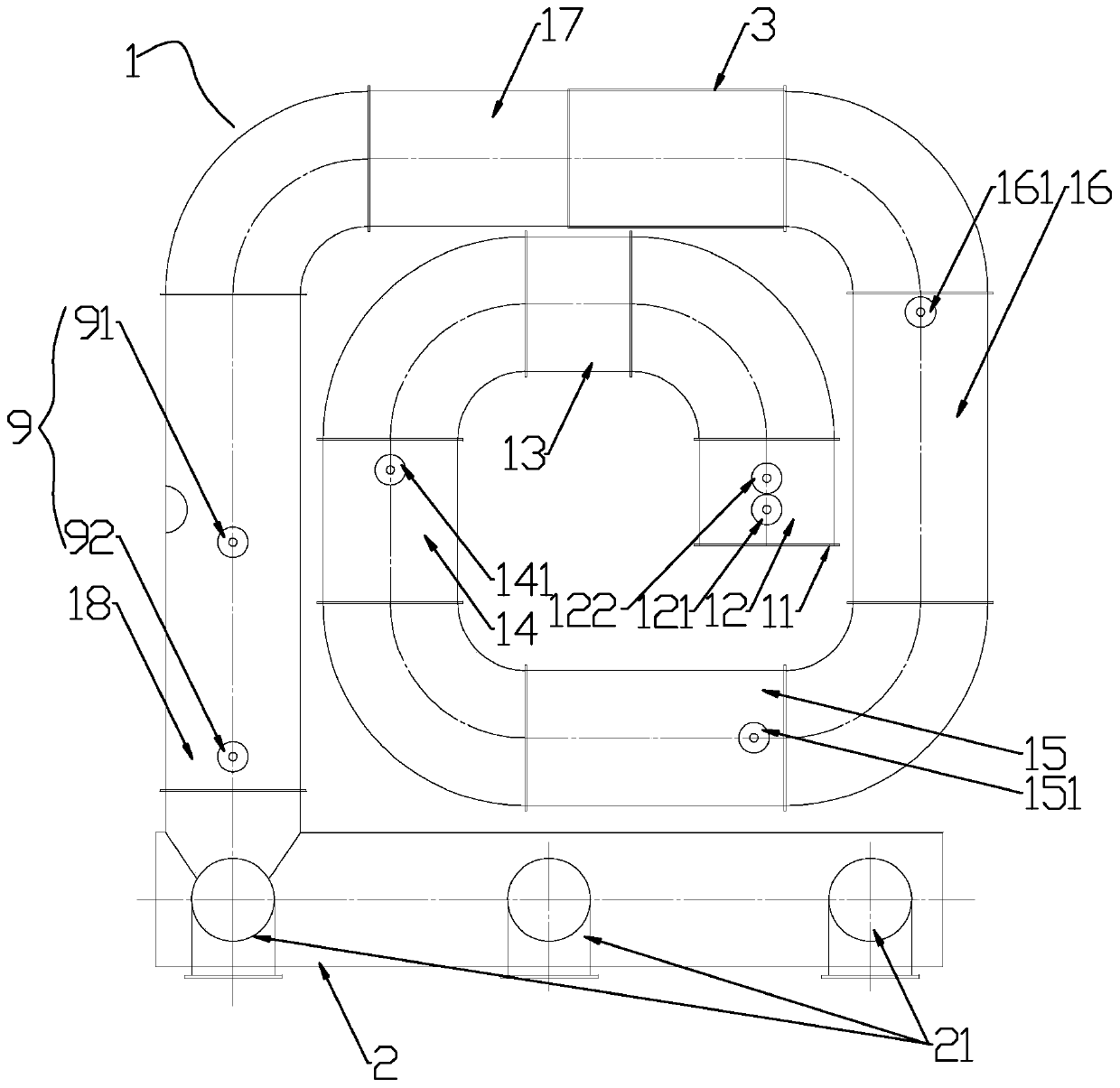

[0017] The present embodiment Fenton reactor, combines figure 1 , including a reaction tube 1 and an output tube 2 (length 7600mm), one end of the reaction tube 1 is provided with an inlet 11, and the other end is connected to the output tube 2, and the side wall of the output tube 2 is provided with an output pump 21, and the output tube 2 is output through the output pump 21. water in tube figure 1 The right side is transported to the next process; one end of the inlet 11 of the reaction tube 1 is sequentially provided with an addition port 121 (preferably set on the central axis of the corresponding pipe section, DN300 / 40mm) and an addition port 2 122 (preferably set at On the central axis of the corresponding pipe section), add ferrous sulfate and hydrogen peroxide respectively, and set the liquid alkali dosing port 9 at the end connecting the reaction tube 1 and the output pipe 2 (preferably set on the central axis of the corresponding pipe section, DN300 / 25mm); The reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com