Expanded perlite foam light soil and preparation method thereof

A technology of expanded perlite and foam light soil, which is applied in the field of building materials, can solve the problems of poor toughness, poor construction stability, and low impact resistance, etc., to improve flexural strength, prevent segregation, improve crack resistance and The effect of durability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

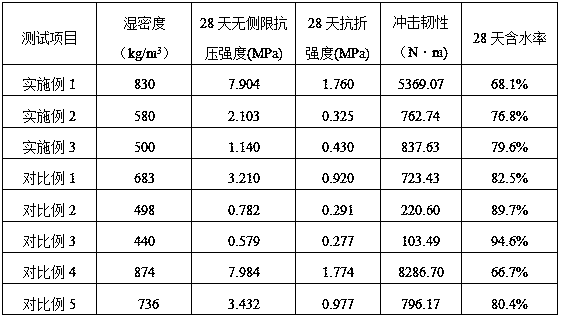

Examples

Embodiment 1

[0041] A kind of expanded perlite foam light soil, comprises the following steps:

[0042] S1. Weigh 155kg of water, add one-third of the water to 9kg of expanded perlite for pre-wetting treatment for 5-10 minutes.

[0043] S2. First, weigh 335kg of cement, 85kg of fly ash, 1.5kg of hydroxypropyl methylcellulose and 40kg of redispersible latex powder and put them into the mixer for initial mixing for 20-30s. Secondly, put the processed expanded perlite into the mixer Continue to stir for 40~60s. Finally, stir the remaining water and 0.5kg polycarboxylate superplasticizer and pour it into the mixer, and continue to stir for 10~15min.

[0044] S3. At the same time, weigh 1.25kg of cement foaming agent and water to dilute at a ratio of 1:50, stir for 2-3 minutes, start the foaming machine for foaming, then add the prepared foam to the expanded perlite cement slurry, and continue stirring 2~3min to form a mixed slurry, and after the mixed slurry is poured and cured, the expanded p...

Embodiment 2

[0046] A kind of expanded perlite foam light soil, comprises the following steps:

[0047] S1. Weigh 178kg of water, add one-third of the water to 18kg of expanded perlite for pre-wetting treatment for 5-10 minutes.

[0048] S2. First, weigh 335kg of cement, 85kg of fly ash, 1.5kg of hydroxypropyl methylcellulose and 20kg of redispersible latex powder and put them into the mixer for initial stirring for 20-30s. Secondly, put the processed expanded perlite into the mixer Continue to stir for 40~60s. Finally, stir the remaining water and 0.5kg polycarboxylate superplasticizer and pour it into the mixer, and continue to stir for 10~15min.

[0049] S3. At the same time, weigh 1.68kg of cement foaming agent and water to dilute at a ratio of 1:50, stir for 2 to 3 minutes, start the foaming machine for foaming, then add the prepared foam to the expanded perlite cement slurry, and continue stirring 2~3min to form a mixed slurry, and after the mixed slurry is poured and cured, the ex...

Embodiment 3

[0051] A kind of expanded perlite foam light soil, comprises the following steps:

[0052] S1. Weigh 193kg of water, add one-third of the water to 27kg of expanded perlite for pre-wetting treatment for 5-10 minutes.

[0053] S2. First, weigh 335kg of cement, 85kg of fly ash, 1.5kg of hydroxypropyl methylcellulose and 40kg of redispersible latex powder and put them into the mixer for initial mixing for 20-30s. Secondly, put the processed expanded perlite into the mixer Continue to stir for 40~60s. Finally, stir the remaining water and 0.5kg polycarboxylate superplasticizer and pour it into the mixer, and continue to stir for 10~15min.

[0054] S3. At the same time, weigh 2.1kg of foaming agent and water to dilute at a ratio of 1:50, stir for 2 to 3 minutes, start the foaming machine for foaming, then add the prepared foam to the expanded perlite cement slurry, and continue stirring for 2 ~3min to form a mixed slurry. After the mixed slurry is poured and cured, the expanded pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com