Slag removal device capable of increasing service cycle of converter oxygen lance and using method of slag removal device

A converter oxygen lance and slag cleaner technology, which is applied in the manufacture of converters, etc., can solve the problems of increasing the service life of the converter oxygen lance, the inability to complete the cleaning of the oxygen lance, and easy damage to the lance body, so as to achieve easy replacement work and reduce replacement Frequency, the effect of reducing manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

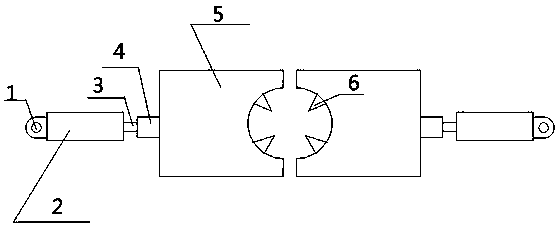

[0023] Such as figure 1 As shown, the slag removal device that increases the service life of the converter oxygen lance includes two solenoid valves 1, two cylinders 2, two push rods 3, two support seats 4, two slag cleaner trolleys 5 and a set of blades 6 , the solenoid valve 1 is connected with one end of the cylinder 2, the air source in the cylinder 2 is controlled by the solenoid valve 1, and the other end of the cylinder 2 is connected with the push rod 3, and the push rod 3 and the slag cleaner trolley 5 are supported by Seat 4 is connected, and described one group of blade 6 is arranged on the semicircle inner wall of slag cleaner trolley 5.

[0024] In this embodiment, one end of the slag cleaner trolley 5 is connected to the support seat 4, and the other end of the slag cleaner trolley 5 is sunken inward to form a semicircle.

[0025] In this embodiment, the two solenoid valves 1 , the two cylinders 2 , the two push rods 3 , the two support seats 4 and the two slag ...

Embodiment 2

[0032] Such as figure 1 As shown, the slag removal device that increases the service life of the converter oxygen lance includes two solenoid valves 1, two cylinders 2, two push rods 3, two support seats 4, two slag cleaner trolleys 5 and a set of blades 6 , the solenoid valve 1 is connected with one end of the cylinder 2, the air source in the cylinder 2 is controlled by the solenoid valve 1, and the other end of the cylinder 2 is connected with the push rod 3, and the push rod 3 and the slag cleaner trolley 5 are supported by Seat 4 is connected, and described one group of blade 6 is arranged on the semicircle inner wall of slag cleaner trolley 5.

[0033] In this embodiment, one end of the slag cleaner trolley 5 is connected to the support seat 4, and the other end of the slag cleaner trolley 5 is sunken inward to form a semicircle.

[0034] In this embodiment, the blade 6 is arranged on the semicircular inner wall of the trolley 5 of the slag cleaner.

[0035] A method f...

Embodiment 3

[0041] Such as figure 1 As shown, the slag removal device that increases the service life of the converter oxygen lance includes two solenoid valves 1, two cylinders 2, two push rods 3, two support seats 4, two slag cleaner trolleys 5 and a set of blades 6 , the solenoid valve 1 is connected with one end of the cylinder 2, the air source in the cylinder 2 is controlled by the solenoid valve 1, and the other end of the cylinder 2 is connected with the push rod 3, and the push rod 3 and the slag cleaner trolley 5 are supported by Seat 4 is connected, and described one group of blade 6 is arranged on the semicircle inner wall of slag cleaner trolley 5.

[0042] In this embodiment, one end of the slag cleaner trolley 5 is connected to the support seat 4, and the other end of the slag cleaner trolley 5 is sunken inward to form a semicircle.

[0043] In this embodiment, the blade 6 is arranged on the semicircular inner wall of the trolley 5 of the slag cleaner.

[0044] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com