Method for producing ultra-pure ferritic stainless steel for decoration by adopting Steckel mill

A kind of furnace coil mill, technology of ultra-pure iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

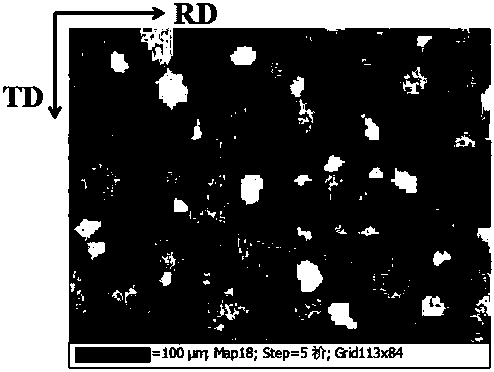

Image

Examples

Embodiment 1

[0033] Embodiment 1, a kind of method that adopts steel coil mill to produce decorative ultra-pure ferritic stainless steel is characterized in that comprising the following steps:

[0034] A. Smelting and continuous casting: smelting and continuous casting of SUS443J1 slab according to the conventional process of VOD-LF refining furnace, its specification is: 220mm (thickness) × 1250mm (width) × 9000mm (length), and its composition mass percentage is: C: 0.015%, Si: 0.30%, Mn: 0.40%, P: 0.02%, S: 0.003%, Ni: 0.25%, Cr: 21.5%, Cu: 0.5%, Nb: 0.1%, Ti: 0.3%, N: 0.010%, the balance is Fe and residual elements;

[0035] B. Grinding: the slab obtained in step A is ground twice with a 16# emery wheel, with a grinding depth of 2.3mm, and with a 20# emery wheel for one time, with a grinding depth of 1.0mm;

[0036] C. Heating in the heating furnace: heat the ground slab obtained in step B to 800°C in the preheating furnace, then enter the heating furnace to continue heating to 1160°C...

Embodiment 2

[0045] Embodiment 2, a method for producing decorative ultra-pure ferritic stainless steel using a steckel mill, is characterized in that it comprises the following steps:

[0046] A. Smelting and continuous casting: smelting and continuous casting of SUS443J1 slab according to the conventional process of VOD-LF refining furnace, its specification is: 220mm (thickness) × 1250mm (width) × 8000mm (length), and its composition mass percentage is: C: 0.010%, Si: 0.40%, Mn: 0.30%, P: 0.03%, S: 0.002%, Ni: 0.3%, Cr: 22.0%, Cu: 0.3%, Nb: 0.16%, Ti: 0.12%, N: 0.015%, the balance is Fe and residual elements;

[0047] B, grinding: the slab obtained in step A is ground twice with a 16# emery wheel, with a grinding depth of 2.5mm, and with a 20# grinding wheel for one time, with a grinding depth of 0.5mm;

[0048] C. Heating furnace heating: heat the ground slab obtained in step B to 750°C in the preheating furnace, then enter the heating furnace and continue heating to 1200°C, and the h...

Embodiment 3

[0056] Embodiment 3, a method for producing decorative ultra-pure ferritic stainless steel using a steckel mill, is characterized in that it comprises the following steps:

[0057] A. Smelting and continuous casting: smelting and continuous casting of SUS443J1 slab according to the conventional process of VOD-LF refining furnace, its specification is: 220mm (thickness) × 1250mm (width) × 8500mm (length), and its composition mass percentage is: C: 0.012%, Si: 0.35%, Mn: 0.20%, P: 0.01%, S: 0.002%, Ni: 0.15%, Cr: 20.5%, Cu: 0.4%, Nb: 0.12%, Ti: 0.18%, N: 0.012%, the balance is Fe and residual elements;

[0058] B, grinding: the slab obtained in step A is ground twice with a 16# emery wheel, with a grinding depth of 2.0mm, and with a 20# grinding wheel for one time, with a grinding depth of 0.8mm;

[0059] C. Heating furnace heating: heat the ground slab obtained in step B to 780°C in the preheating furnace, then enter the heating furnace and continue heating to 1180°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com