Air blast cooling mechanism for gray fabric singeing frame

A technology of blowing and cooling, singeing machine, applied in singeing, heating/cooling fabric, mechanical cleaning, etc., can solve problems such as affecting processing, and achieve the effect of ensuring normal processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

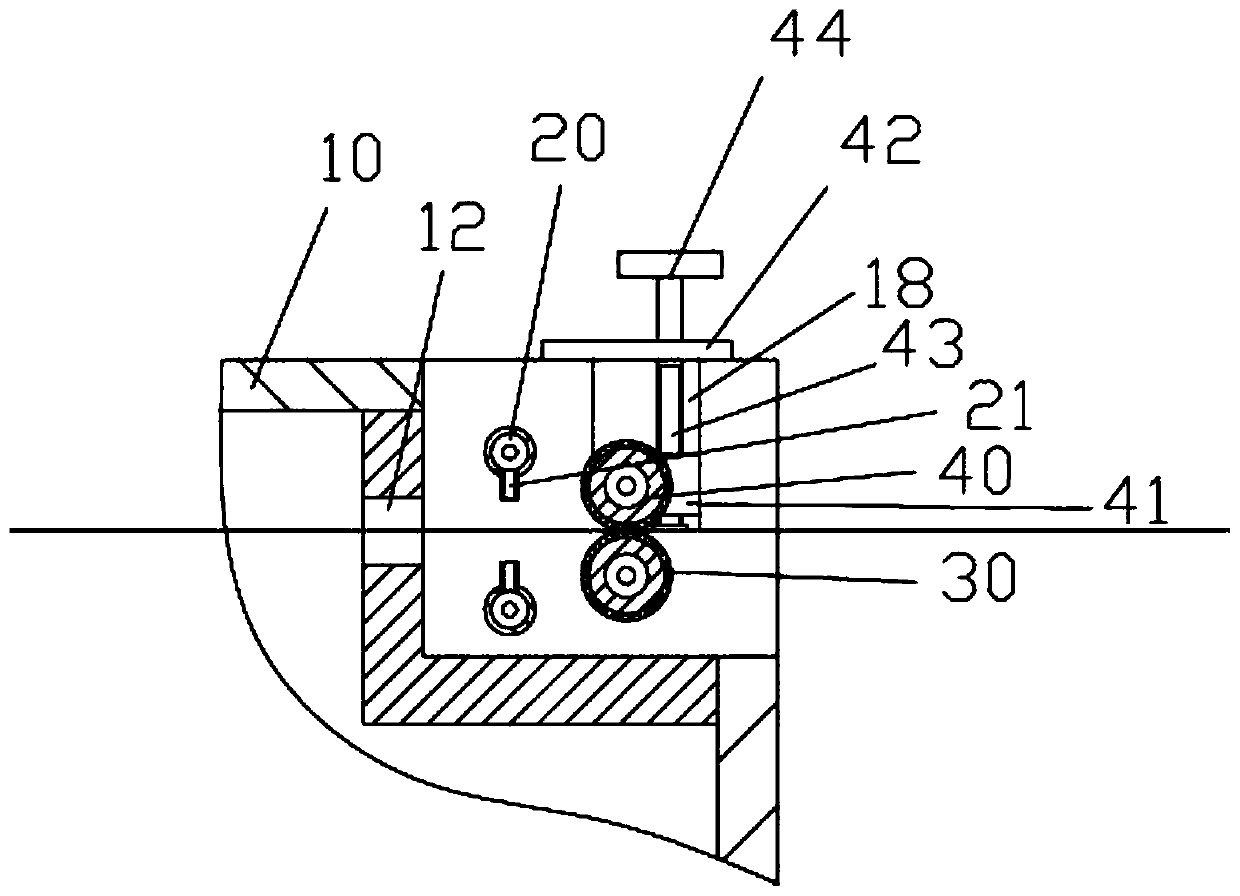

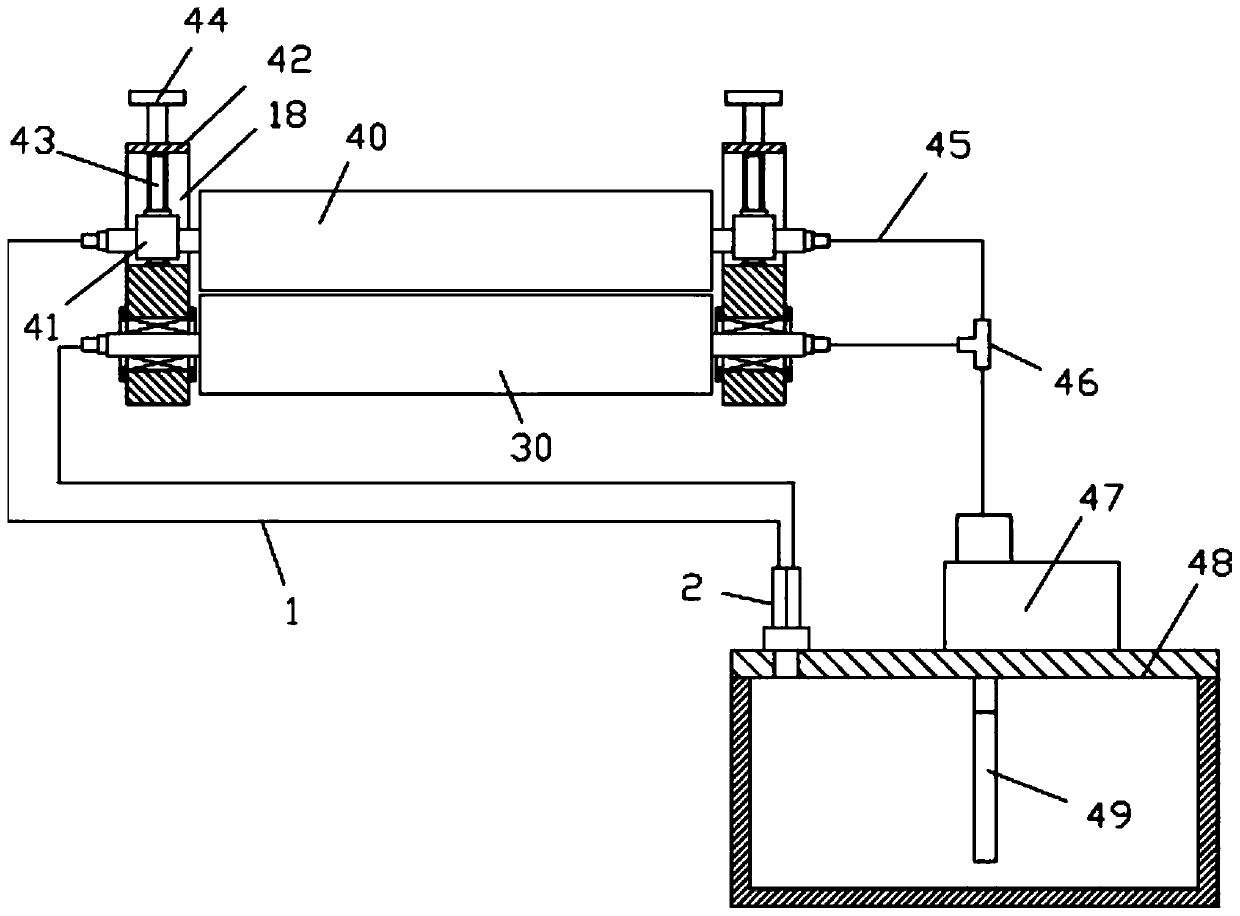

[0018] Examples, see e.g. figure 1 and image 3 As shown, a blowing cooling mechanism for fabric gray cloth singeing machine includes a box body 10, the upper right side wall of the box body 10 is formed with a discharge port 12, and the case body at the right side of the discharge port 12 Two blowing main pipes 20 are arranged on the front and rear two side plates of 10, and the two blowing main pipes 20 are located above and below the gray cloth protruding from the outlet 11. The side walls of the blowing main pipes 20 are connected with blowing branch pipes 21. The end of branch pipe 21 faces the top and bottom of gray cloth;

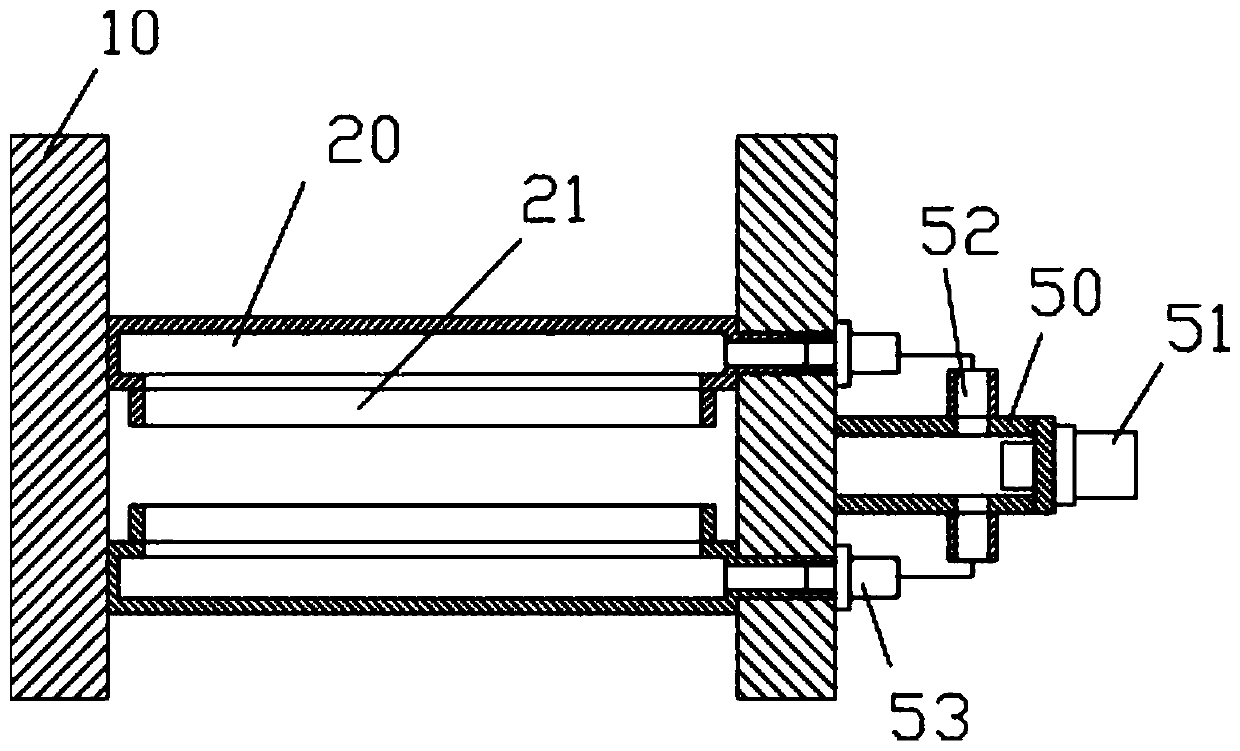

[0019] A lower cooling roll 30 and an upper cooling roll 40 are arranged on the front and rear sides of the box body 10 on the right side of the two blowing main pipes 21 , and the gray cloth is between the lower cooling roll 30 and the upper cooling roll 40 .

[0020] Furthermore, both ends of the lower cooling roller 30 are hinged to the front an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com