Back-attached heat-insulation plate structure

A technology of thermal insulation and backboard, which is applied in thermal insulation, building structure, building components, etc., and can solve the problems of single structure of thermal insulation board and inability to realize thermal insulation and fire prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

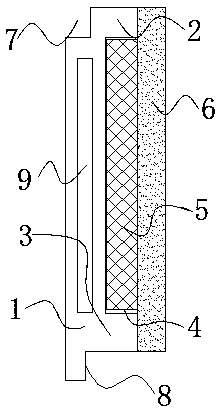

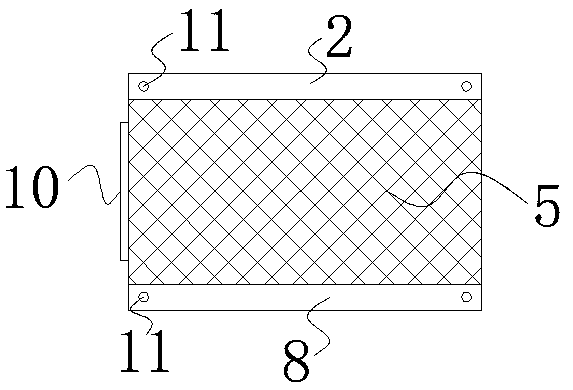

[0029] Such as Figure 1-3 As shown, the embodiment of the present invention provides a back-attached heat insulation board structure, including a first backboard 1, the upper and lower sides of the first backboard 1 are respectively fixed with a first convex plate 2 and a second convex plate 3, A connection plane is provided, and the length of the first protruding plate 2 and the second protruding plate 3 are the same as the plate width of the first back plate 1, and a groove 4 is fixedly formed between the first protruding plate 2 and the second protruding plate 3, providing In the connection position of the inner plate, the inside of the groove 4 is fixedly connected with the attached plate 5, which increases the overall thermal insulation performance of the insulation board, and the upper surface of the attached plate 5 is on the surface with the upper surface of the first convex plate 2 and the second convex plate 3. The surface is the same, and the outer surface of the a...

Embodiment 2

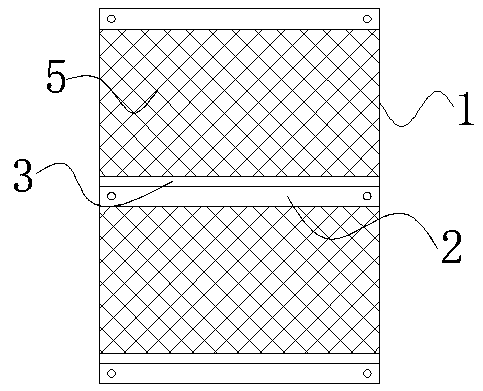

[0032] Such as figure 1 , 4 , 5 shows that the embodiment of the present invention provides a back-attached heat insulation board structure, including a second backboard 12, the second backboard 12 is provided with two front and back panels to ensure the docking operation on both sides, and the front and back panels are fixed to form The second backboard 12, and the two sides of the second backboard 12 have the same structure, and the middle position of the second backboard 12 on one side is fixedly provided with a groove 4, which provides a board connection position, and the second backboard 12 on one side is fixedly provided with a groove 4. Protrusions 13 are fixedly arranged on both sides of the upper side respectively, and a second anchor hole 14 is fixedly arranged in the middle of the protrusion 13 to provide an anchoring position. Projections 13 are also arranged on both sides of the middle and lower sides of the second back plate 12, and the second back plate 12 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com