Keyboard type input coded lock made of aluminium magnesium alloy

An aluminum-magnesium alloy and combination lock technology, applied in the field of new material production equipment, can solve problems such as inability to open, difficult to open, rusted car locks, etc., and achieve the effects of convenient and fast use, low application cost, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

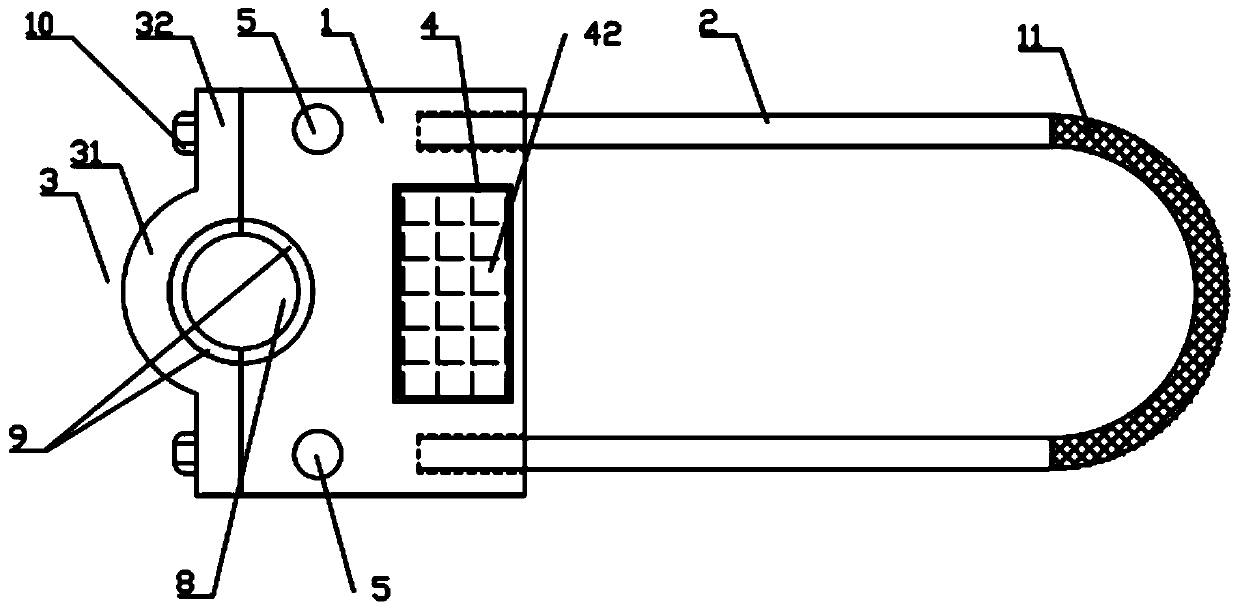

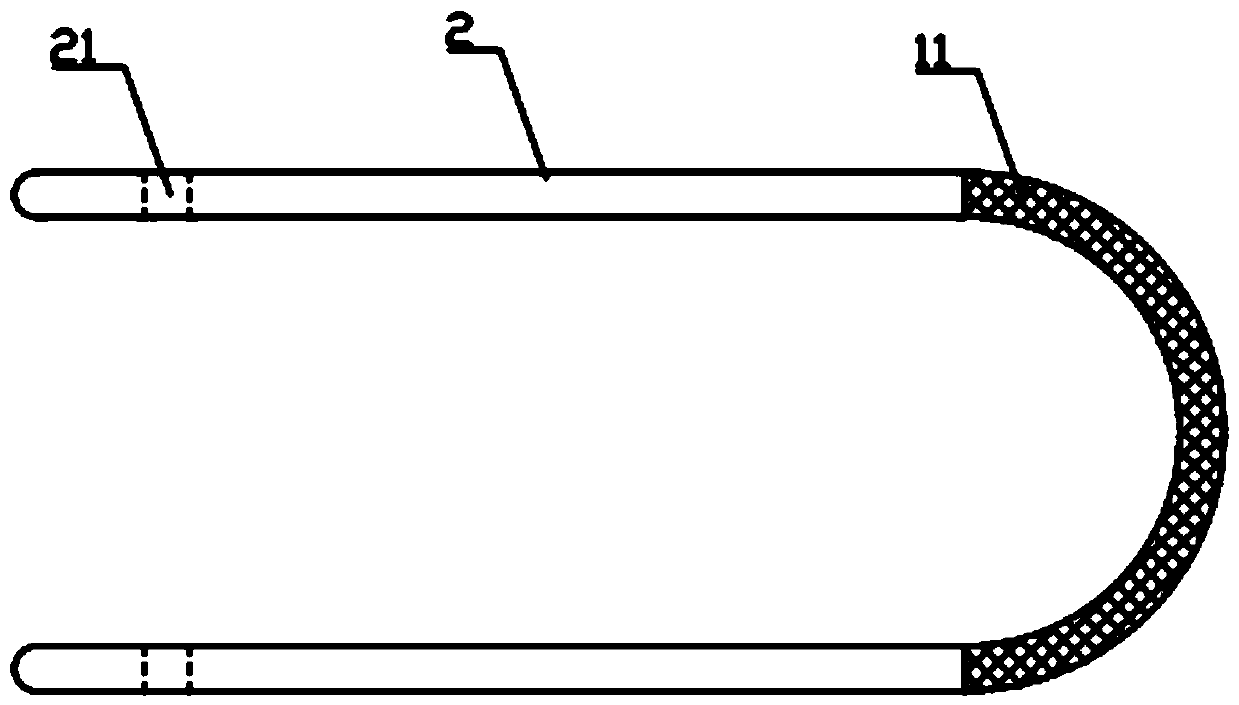

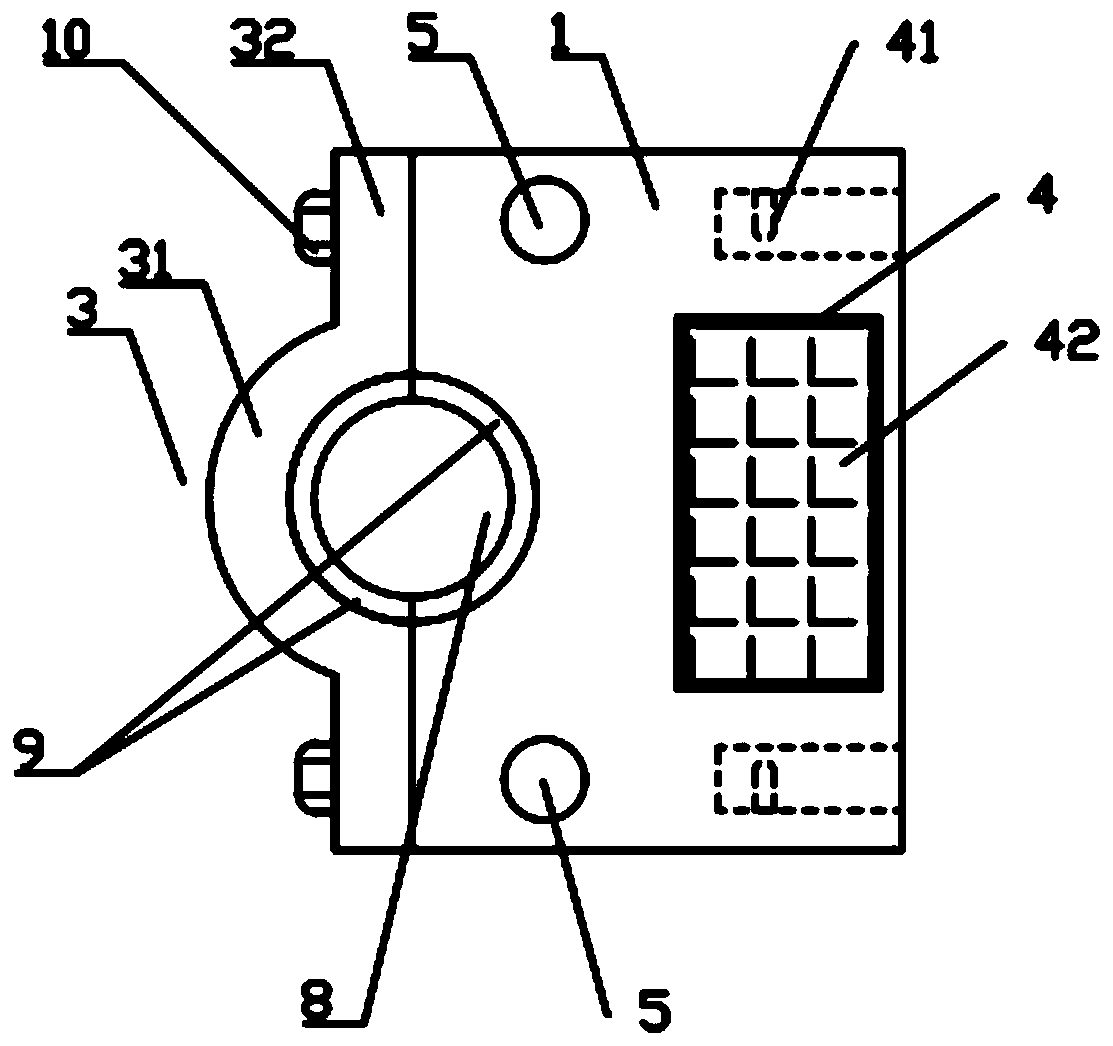

[0062] Such as figure 1 The shown keyboard-type input code lock adopting aluminum-magnesium alloy includes a bicycle lock body 1, a U-shaped lock bolt 2, a hoop 3 and an electronic lock 4. The electronic lock 4 is arranged on the bicycle lock body 1, and the card The hoop 3 is connected with the bicycle lock body 1, and the lock end of the U-shaped lock bolt 2 is arranged in the bicycle lock body 1, and is locked by the electronic lock 4; wherein the electronic lock 4 includes a lock catch 41 and an input keyboard 42, the The input keyboard 42 controls the opening and closing of the buckle 41 , and the input keyboard 42 is arranged on the surface of the bicycle lock body 1 . Wherein, the bicycle lock body 1 is provided with a fixing hole 5, so that the bicycle is not locked, and the U-shaped lock bolt 2 is placed in the fixing hole 5. In addition, in order to secure the bicycle lock to the bicycle, such as image 3 As shown, a clamp 3 is provided, and the clamp 3 includes a ...

Embodiment 2

[0065] Based on the structure of Embodiment 1, the bicycle lock body 1 and the U-shaped lock bolt 2 are made of aluminum-magnesium alloy, and the composition and weight ratio of the aluminum-magnesium alloy are:

[0066] Al: 10.5-11.5 parts,

[0067] Mn: 0.17-0.40 parts,

[0068] Zn: 0.45-0.90 parts,

[0069] Be: 0-0.0015 parts,

[0070] Cr: 0.1-0.5 parts,

[0071] Ti: 0.1-0.5 parts,

[0072] Si: ≤0.08 parts,

[0073] Fe: ≤0.004 parts,

[0074] Cu: ≤0.025 parts,

[0075] Ni: ≤0.001 parts,

[0076] Mg: ≤0.002 parts.

[0077] The preparation method of the above-mentioned aluminum-magnesium alloy comprises the following steps:

[0078] A. Put Al, Si, Mg, Mn, Zn, Be, Cr, Ti, Fe, Cu, Ni into the crucible and add bottom flux to melt. The amount of bottom flux accounts for 1.5-2.5% of the total charge. Covering agent is added to prevent burning. The amount of covering agent accounts for 0.3-0.5% of the total charge, the entire melting process time is controlled at 4-6h, and...

Embodiment 3

[0103] Based on the structure of Embodiment 1, the bicycle lock body 1 and the U-shaped lock bolt 2 are made of aluminum-magnesium alloy, and the composition and weight ratio of the aluminum-magnesium alloy are:

[0104] Al: 10.5 parts,

[0105] Mn: 0.17 parts,

[0106] Zn: 0.45 parts,

[0107] Be: 0.001 parts,

[0108] Cr: 0.1 parts,

[0109] Ti: 0.1 part,

[0110] Si: ≤0.08 parts,

[0111] Fe: ≤0.004 parts,

[0112] Cu: ≤0.025 parts,

[0113] Ni: ≤0.001 parts,

[0114] Mg: ≤0.002 parts.

[0115] The preparation method of the above-mentioned aluminum-magnesium alloy comprises the following steps:

[0116]A. Put Al, Si, Mg, Mn, Zn, Be, Cr, Ti, Fe, Cu, Ni into the crucible and add bottom flux to melt. The amount of bottom flux accounts for 1.5-2.5% of the total charge. Covering agent is added to prevent burning. The amount of covering agent accounts for 0.3-0.5% of the total charge, the entire melting process time is controlled at 4-6h, and the final temperature of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com