Automatic deviation rectifying device for hydraulic drill

An automatic deviation correction device and hydraulic technology, applied in the field of drilling, can solve the problems of uneven wear, increased workload, and casing not centered, etc., and achieve the effects of efficient deviation correction operation, guarantee of neutrality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

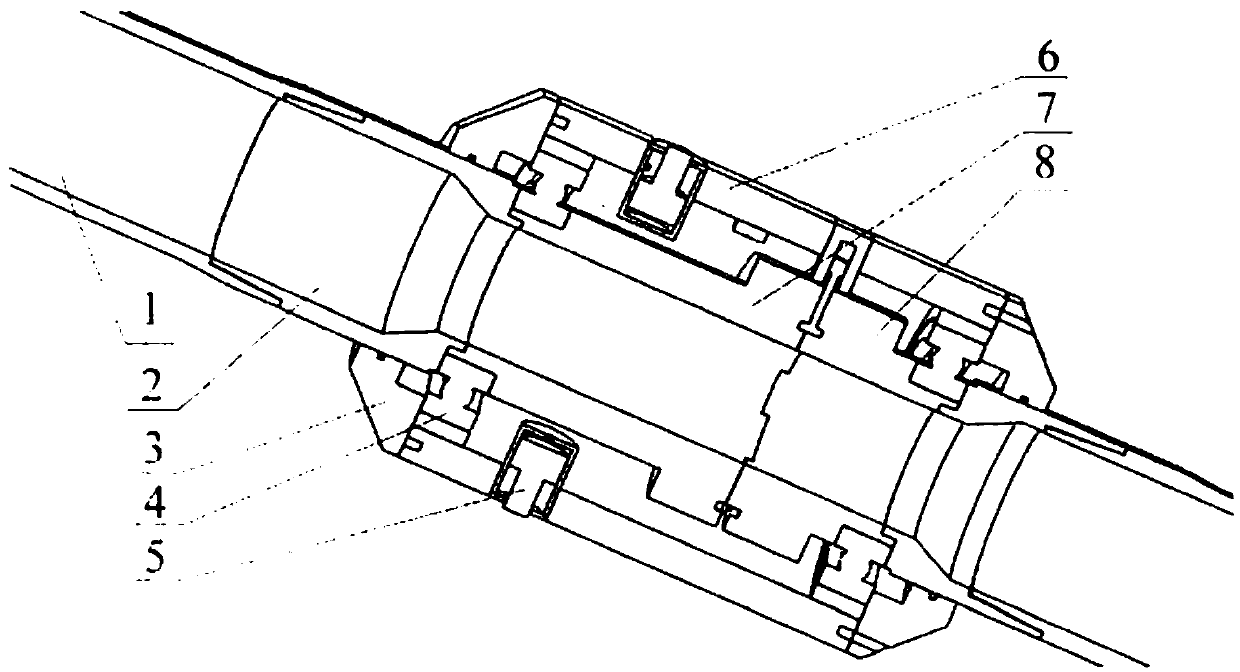

[0015] Such as figure 1 As shown, an automatic deviation correction device for a hydraulic drill includes an inner rod, an outer sleeve, a hydraulic system and a Bluetooth module. The inner rod includes a special inner rod and a drill pipe adapter, the special inner rod is hollow, and the The special inner rod is connected with the drill pipe joint, and an eccentric annular groove is dug inside the special inner rod, and a rod with a cylindrical end is embedded in the groove.

[0016] The outer sleeve includes: the sleeve body and 2 end caps. The sleeve body is sleeved on the outside of the special inner rod through bearings. There are four small thrust hydraulic cylinders evenly distributed on its circumference. The two end caps are respectively set on the At both ends of the sleeve body, a through hole is opened in the center of the end cap, and the size of the through hole corresponds to the outer diameter of the special inner rod. An eccentric annular groove is dug in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com