Bonging intensity testing method of stainless steel back pipe and high-purity copper targeted material

A technology of bonding strength and stainless steel, applied in measuring devices, analysis materials, instruments, etc., can solve problems such as sample deviation, insufficient fastening force, and large test data, and achieve controllable fastening force process, precise bonding strength, Reduce the effect of force deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

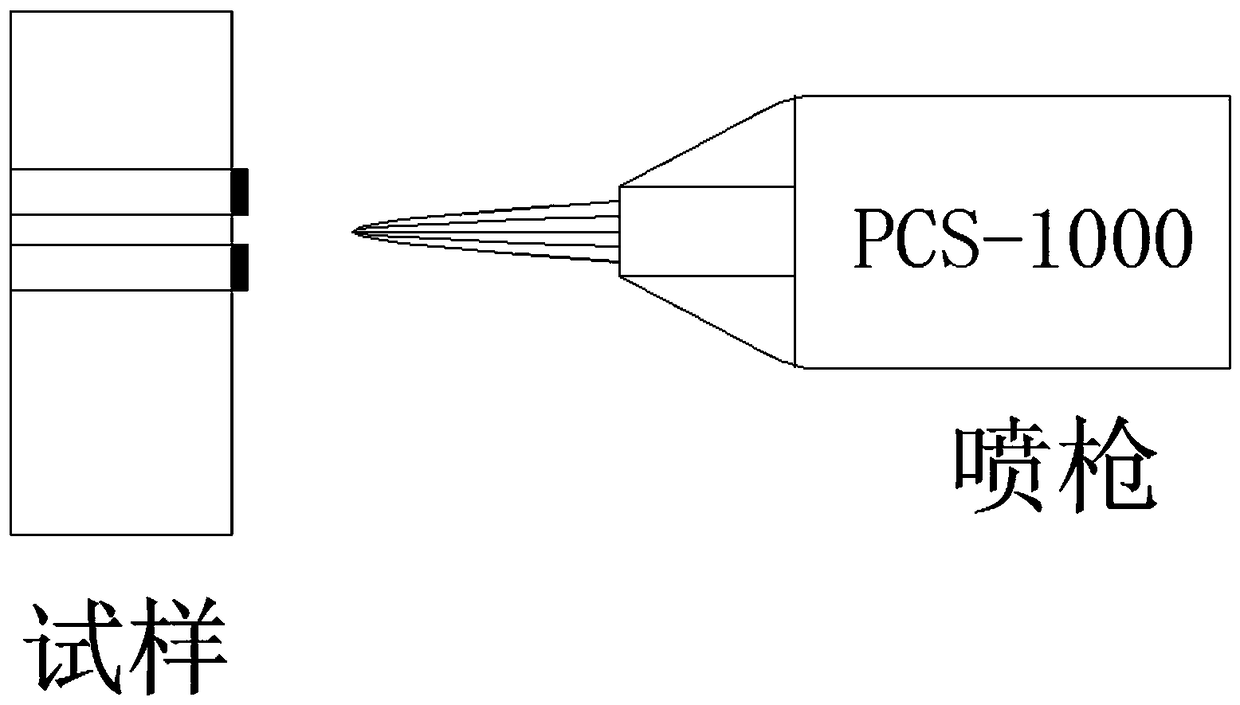

[0022] The method for testing the bonding strength of the stainless steel back tube and the high-purity copper target of the present invention is as follows:

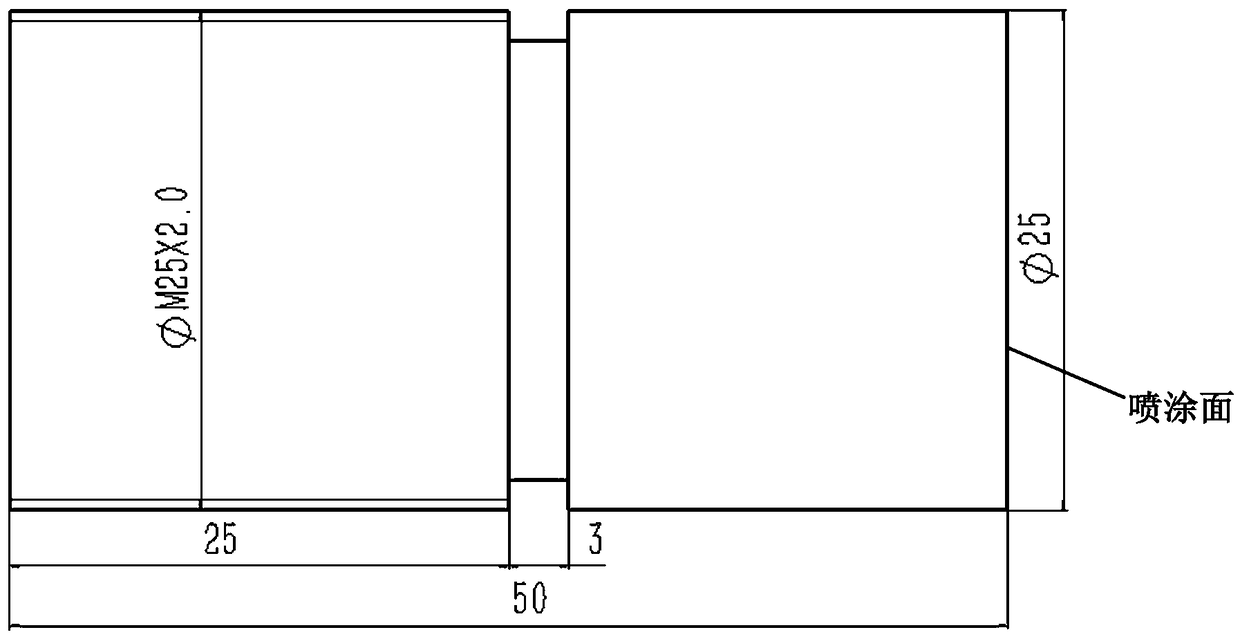

[0023] First, select an externally threaded 316L stainless steel back pipe with a diameter of 25mm and a length of 50mm, such as figure 1 shown;

[0024] Then, use a grinder to do flat surface treatment on the sprayed surface of the external thread 316L stainless steel back pipe, so that the sprayed surface is formed into a smooth surface, and the circular runout does not exceed 0.5mm, such as figure 1 As shown, the sprayed surface is one end surface of the stainless steel back pipe;

[0025] Next, use acetone to degrease the externally threaded 316L stainless steel back pipe, and use ultrasonic waves to wash with alcohol. The alcohol should soak the entire externally threaded 316L stainless steel back pipe. , the drying temperature is 100°C, and the drying time is 40 minutes. During the drying process, the sprayed su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com