Bearing clamp for nanometer stretching instrument and related experimental method

A nano-stretcher and fixture technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve problems such as sticking and clamping difficulties, residual stress of paper cards, and affecting experimental efficiency. Achieve the effect of simplifying the clamping process, reducing the cost of the experiment, and reducing the difficulty of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

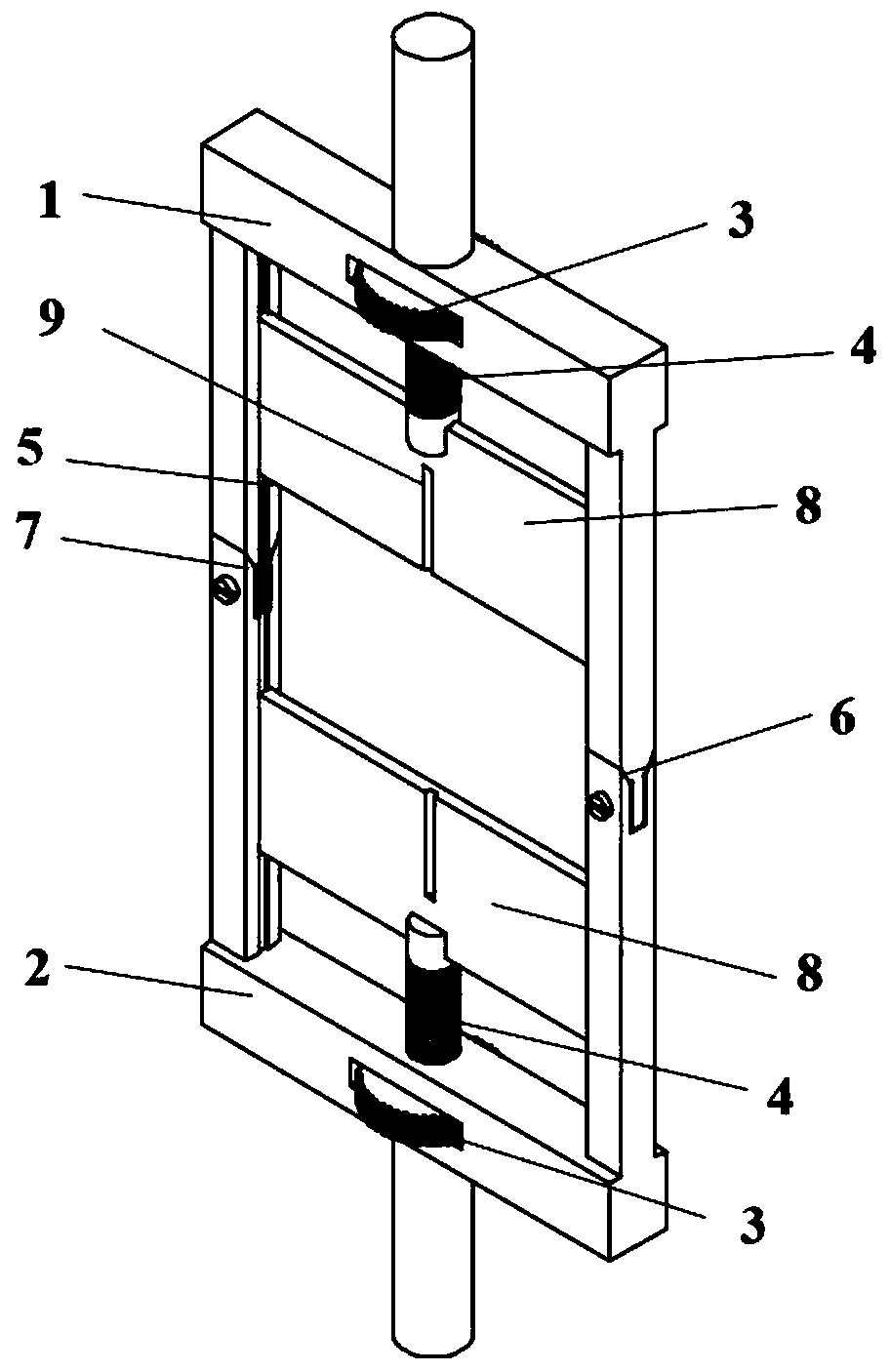

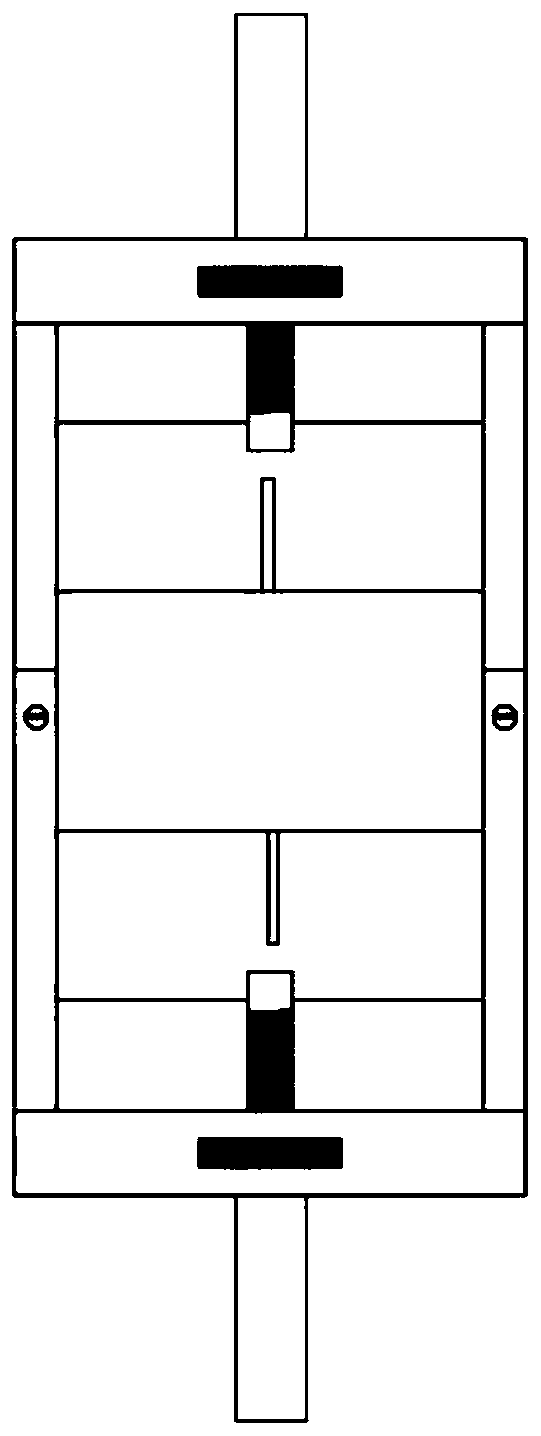

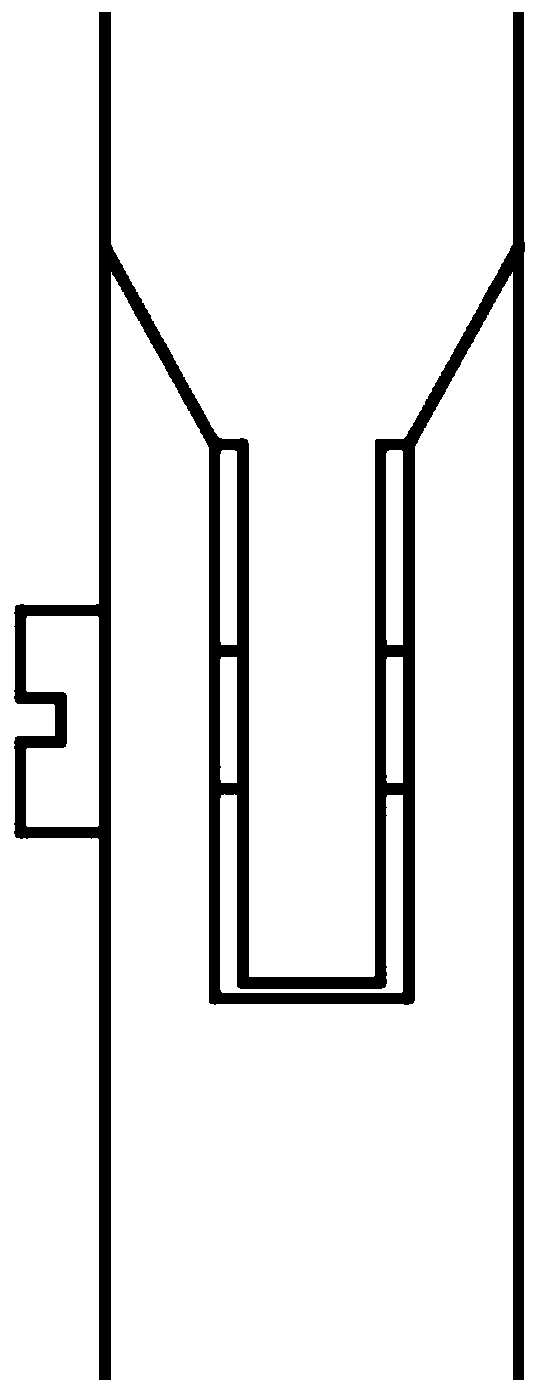

[0021] A bearing fixture for a nanometer stretcher, in which an upper clamp (1) and a lower clamp (2) are centered through a limiting groove (6) and fixed with pins (7). The specimen slide (8) is installed in the rail groove (5) and connected with the lead screw (4), and the two specimen slides (8) can be controlled by adjusting the nut (3) to control the specimen slide (8) to move up and down The spacing is suitable for different lengths of experimental materials. The adjusting nut (3) and the leading screw (4) can realize self-locking, so as to ensure that the loading piece (8) does not move up and down during the stretching process. A sample groove (9) is arranged on the loading sheet (8) for placing the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com