Separated layer water-flooding process tubular column capable of being drilled

A technology of pipe string and layered water injection, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problems of serious scaling and difficulty in unsealing tools, and achieve the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

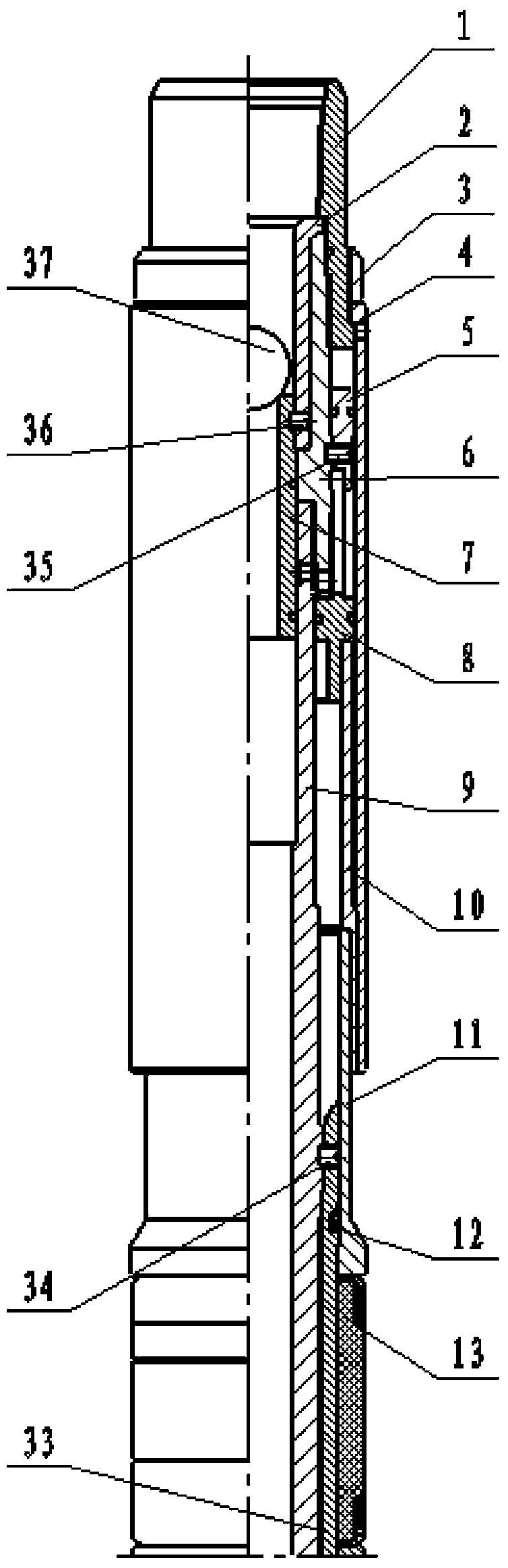

[0023] like figure 1 , 2 As shown, upper joint-1, positioning sleeve-2, back cap-3, cylinder barrel-4, auxiliary piston-5, connecting sleeve-6, sliding sleeve-7, main piston-8, central tube-9, thrust sleeve -10, ball seat-18, retaining ring-29, spring-30, steel ball I-31, steel ball II-37 form the sealing tool.

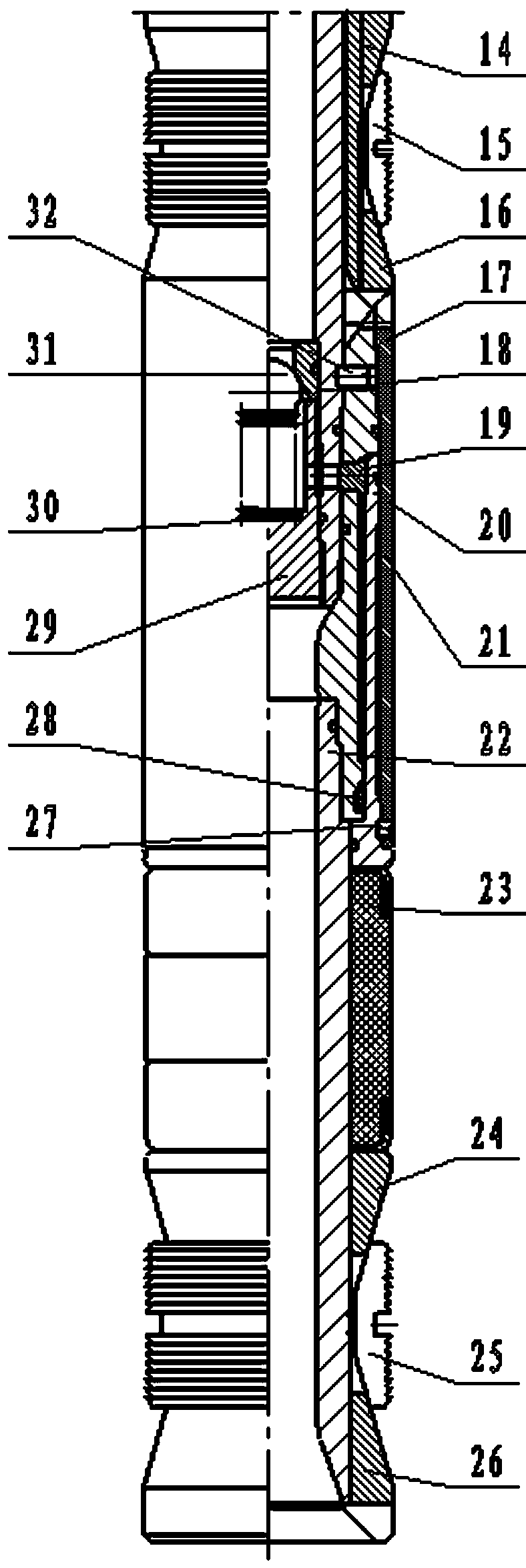

[0024] Upper pressure ring-11, lock spring I-12, upper rubber cylinder-13, upper cone I-14, upper slips-15, lower cone I-16, upper rubber cylinder shaft-33, auxiliary piston scissors- 35. The sliding sleeve shear nail-36 forms the upper plugging tool.

[0025] Sealing sleeve-17, block-19, lower main piston-20, lower cylinder liner-21, lower rubber cylinder shaft-22, lower rubber cylinder-23, upper cone II-24, lower slips-25, lower cone Body II-26, setting shear nail-27, and lock spring II-28 form the lower plugging tool.

[0026] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com