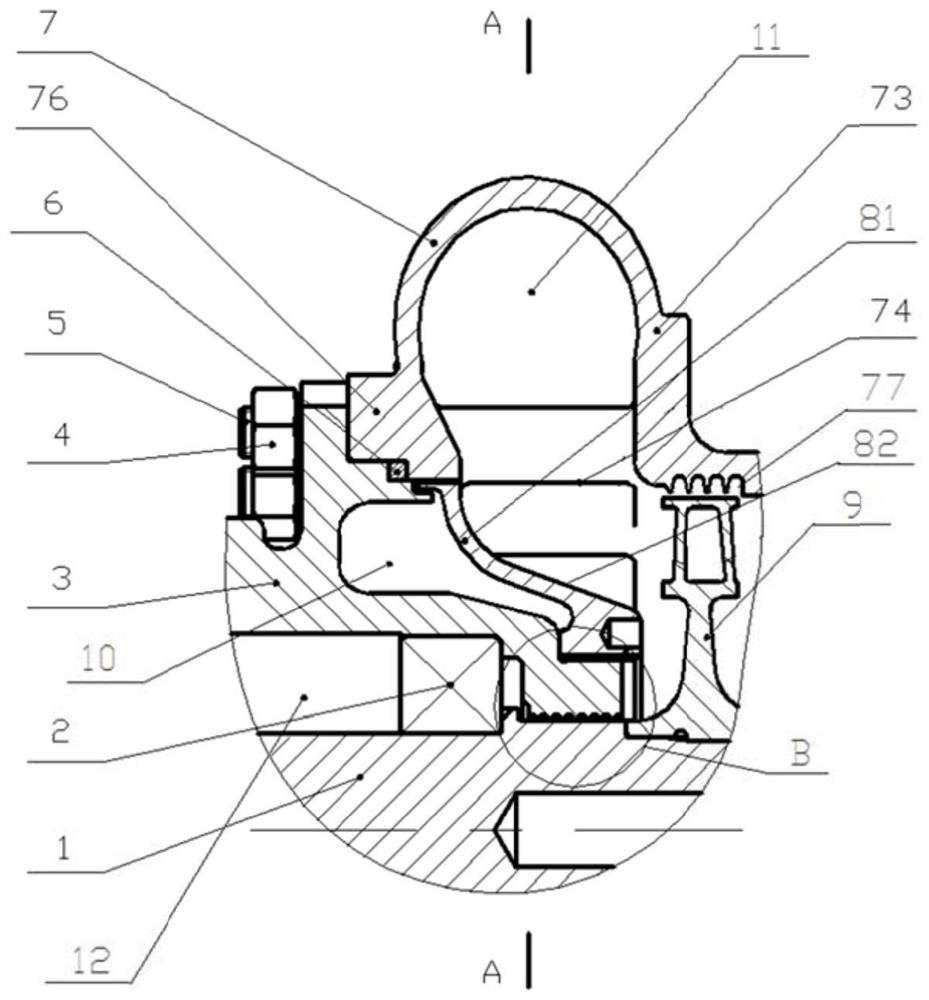

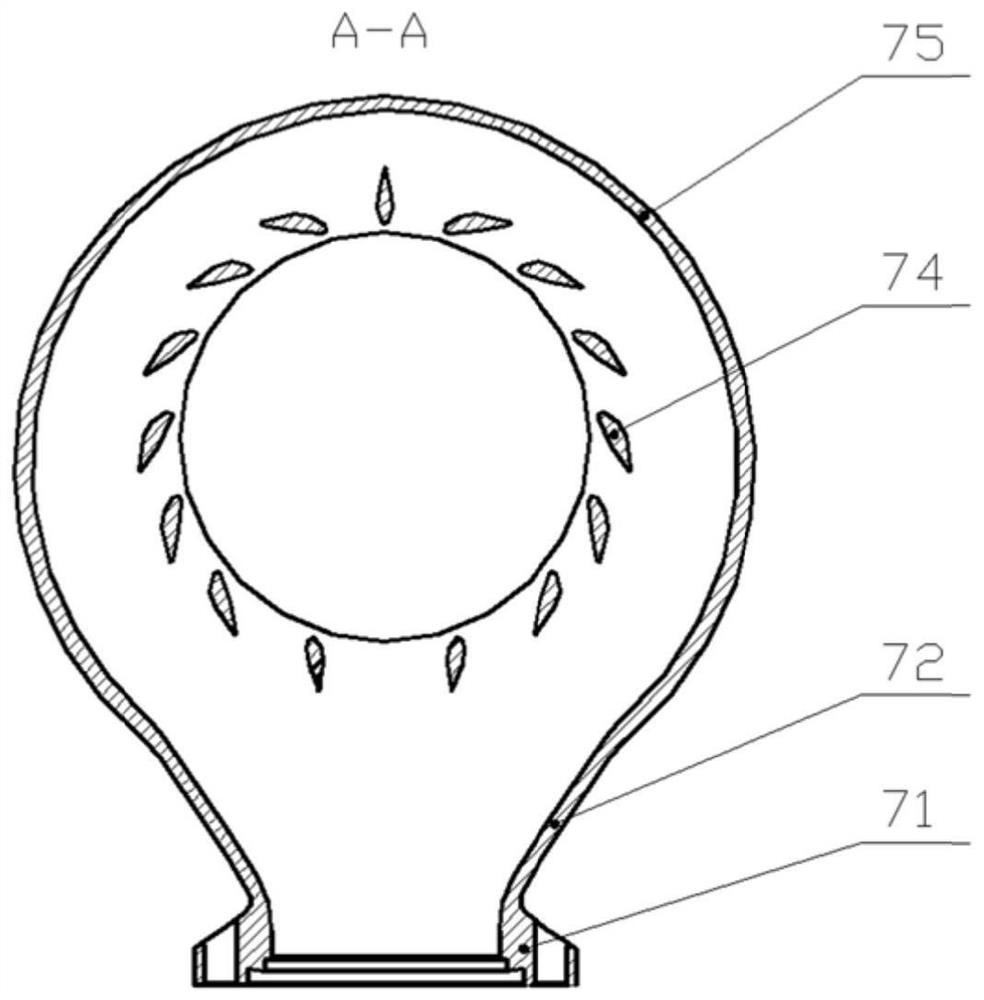

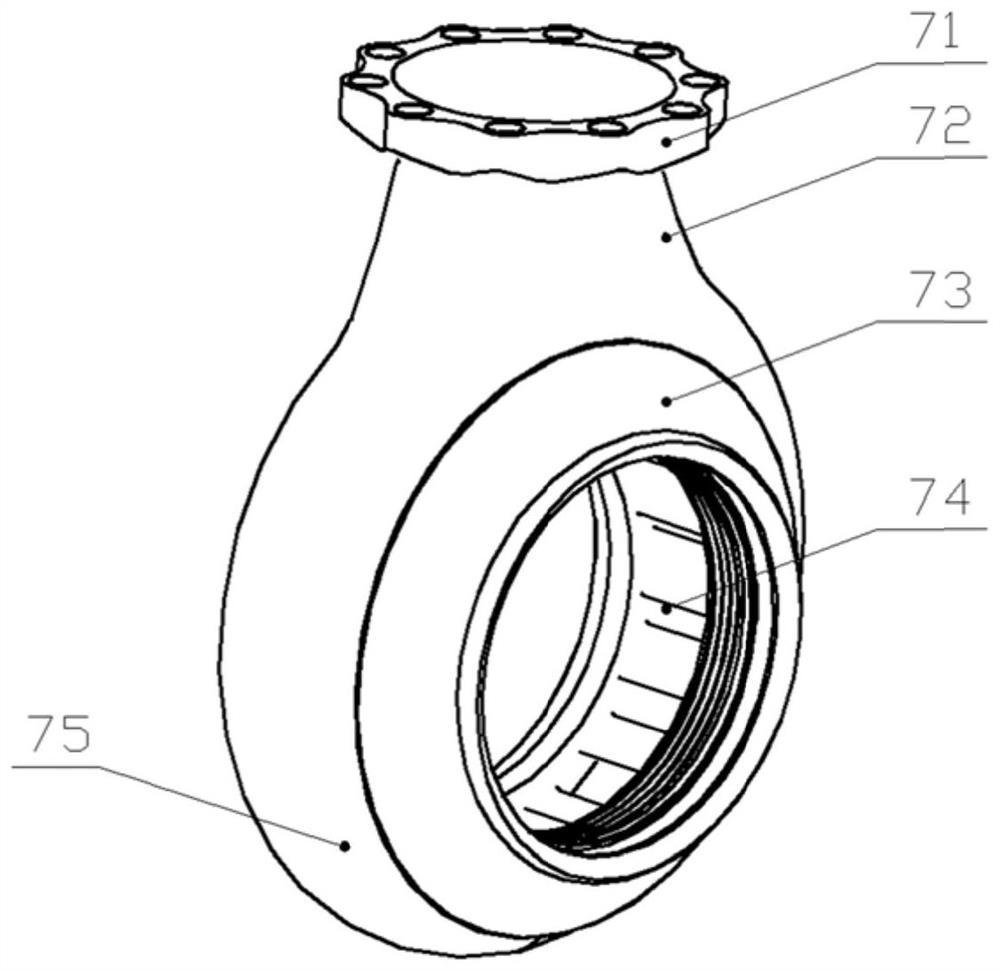

A connection structure of high temperature gas outlet end of low temperature turbo pump

A technology of gas outlet and connection structure, which is applied to jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of component deformation and large temperature difference, reduce temperature difference, reduce leakage, and improve working ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The working mode of the post-combustion cycle engine is as follows: After the fuel and oxidant are pressurized by the pump, a small part of the fuel and the entire flow of oxidant enter the pre-combustion chamber, and the combustion in the pre-combustion chamber generates high-temperature, high-pressure oxygen-enriched gas to drive the main engine. When the turbine works, the oxygen-enriched gas enters the main combustion chamber through the pipeline after the turbine, where it merges with most of the fuel after the pump and burns fully, and is discharged from the nozzle. The invention is based on the idea of improving the efficiency of the turbo pump to reduce the temperature of the high-temperature gas so as to ensure the reliability of the overall operation of the turbo pump, optimize the structure of the high-temperature gas outlet pipe to improve the efficiency of the turbo pump, and at the same time through the connection assembly between the high-temperature gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com