Flue gas quenching device and method.

A flue gas quenching and flue gas technology, applied in the direction of combustion method, water shower cooler, combustion product treatment, etc., can solve the problems of unfeasible recycling, environmental pollution, etc., and achieve the effect of reducing operating costs and avoiding bridging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

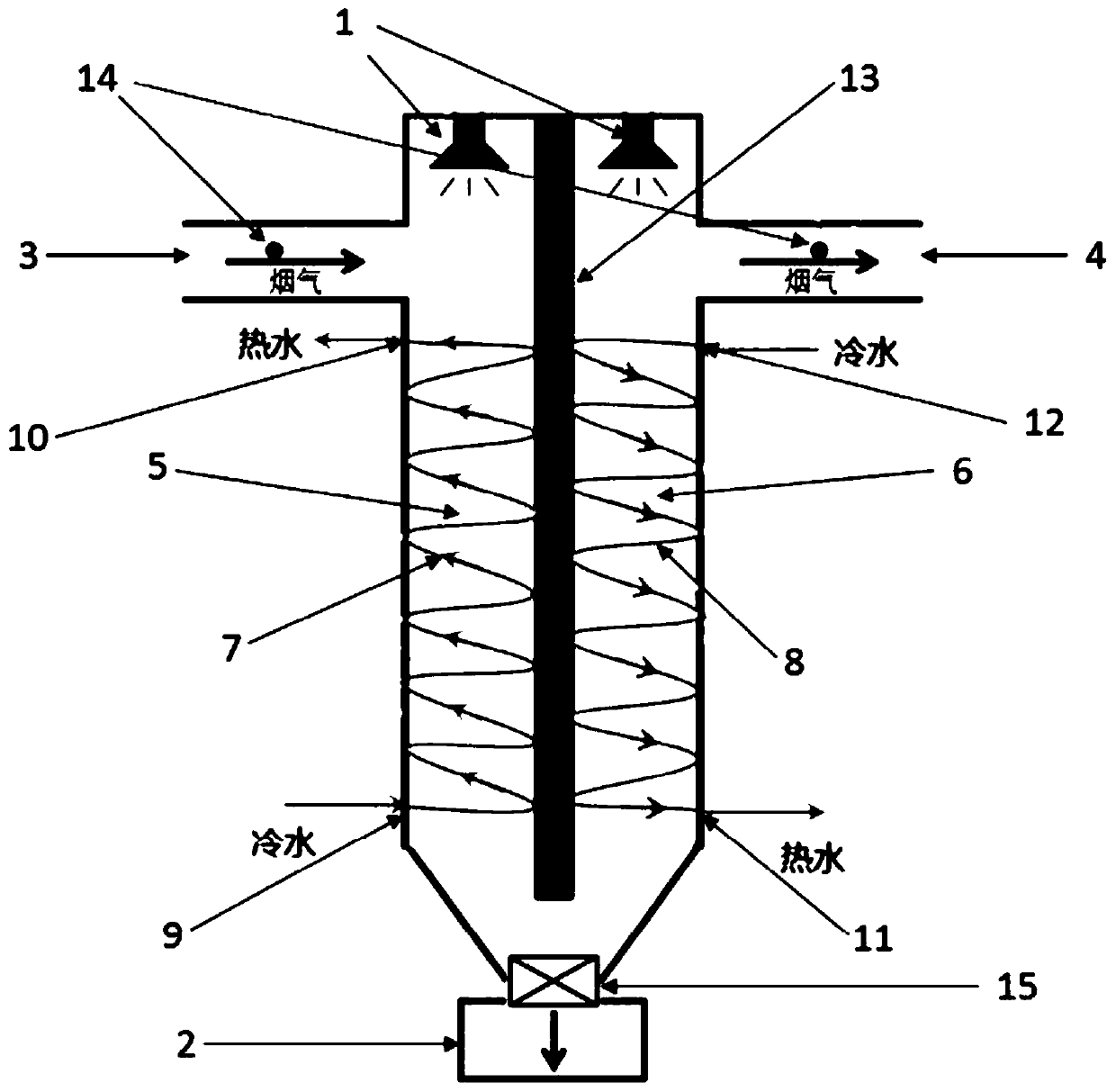

[0039] This embodiment provides a flue gas quenching device, figure 1 It is a structural schematic diagram of the quenching device of the present invention, as shown in the figure, including: a casing, an atomizing sprayer 1, and an ash collecting box 2, and the casing is provided with a flue gas inlet 3 and a flue gas outlet 4, and the atomizing sprayer The water container 1 is arranged in the casing and above the smoke inlet 3 and / or the smoke outlet 4, and the ash collecting box 2 is arranged below the casing and connected to the bottom of the casing.

[0040] Specifically, the flue gas enters the device from the flue gas inlet 3, and the atomizing sprinkler 1 sprays water to cool down the high-temperature flue gas entering the device, and the cooled flue gas is discharged from the flue gas outlet 4. A large amount of fly ash will be produced during the cooling of the flue gas, and these fly ash will descend and settle, and will be collected by the ash collecting box 2 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com