An automatic cleaning mechanism for a compression spring track eccentric bearing

A technology for automatic cleaning and eccentric bearings, which is applied in vibration cleaning, cleaning heat transfer devices, lighting and heating equipment, etc., and can solve problems such as uneven cleaning of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

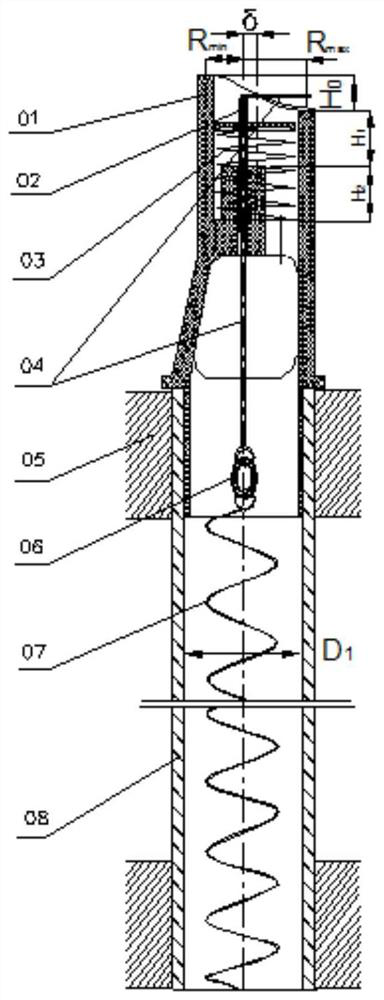

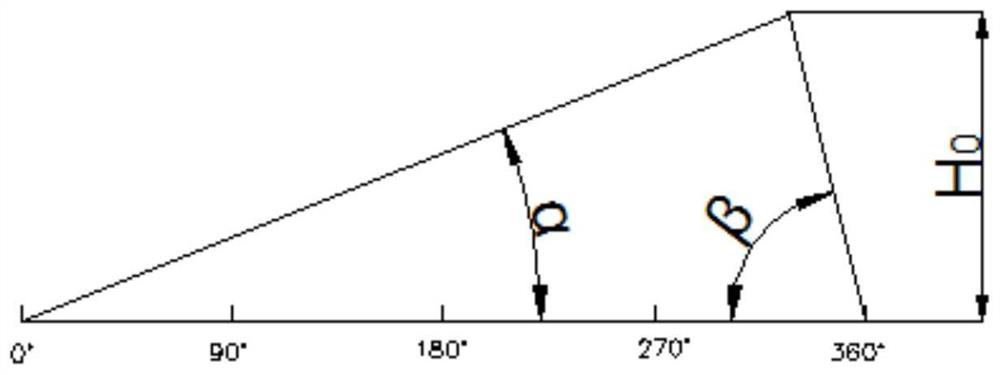

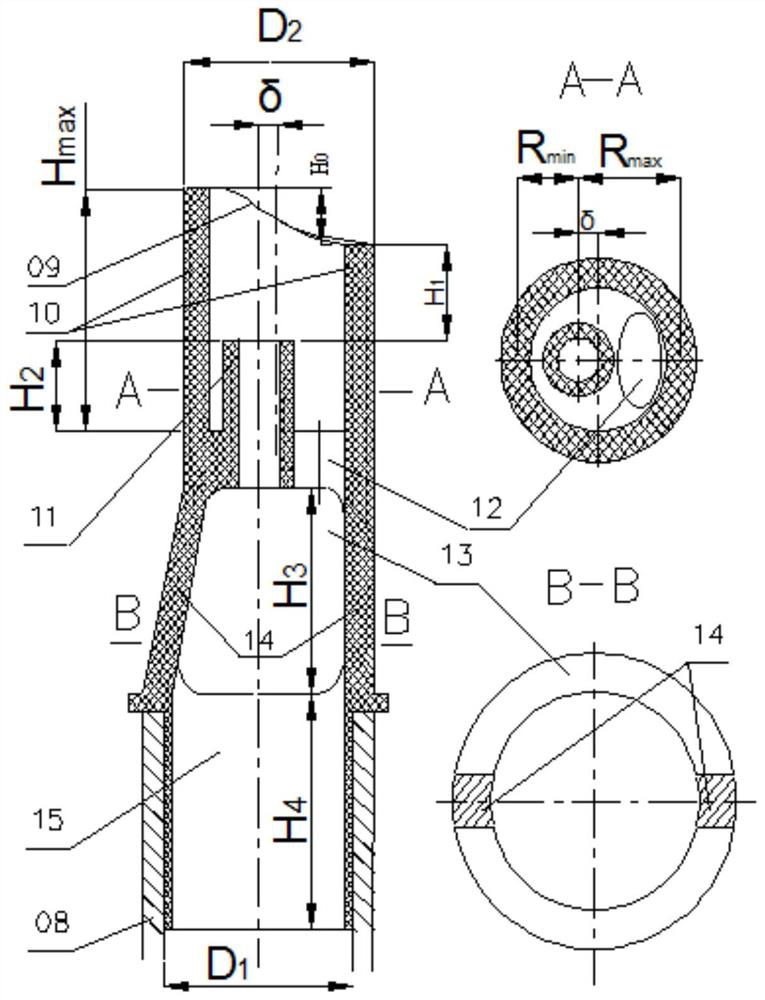

[0018] Attached below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the present invention is described in further detail.

[0019] In the figure: 1 track end face bearing 2 floating end face bearing 3 compression spring 4 hook head shaft 5 tube plate 6 wear-resistant plastic ring 7 cleaning spiral 8 heat exchange tube 9 track end face 10 track cylinder 11 positioning bearing seat 12 flow hole 13 Entrance window 14 Support rib plate 15 Fixed pipe section 16 Floating positioning shaft 17 Floating plate 18 Floating bearing 19 Spring worm thread head 20 Cylindrical spring section

[0020] The technical scheme of the patent of the present invention is: an automatic cleaning mechanism for the compression spring track eccentric bearing, the main components are track end bearing 1, floating end bearing 2, compression spring 3, cleaning screw 7, hook shaft 4, wear-resistant plastic ring 6. Heat exchange tube 8. The floating end bearing 1 and the compression spring 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com