Surfing cleaning type reverse nature circular evaporator

A technology of natural circulation and reverse circulation, applied to evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of low production efficiency and high energy consumption of evaporation, achieve strong automatic cleaning function, high-efficiency desalination cleaning, and improve The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

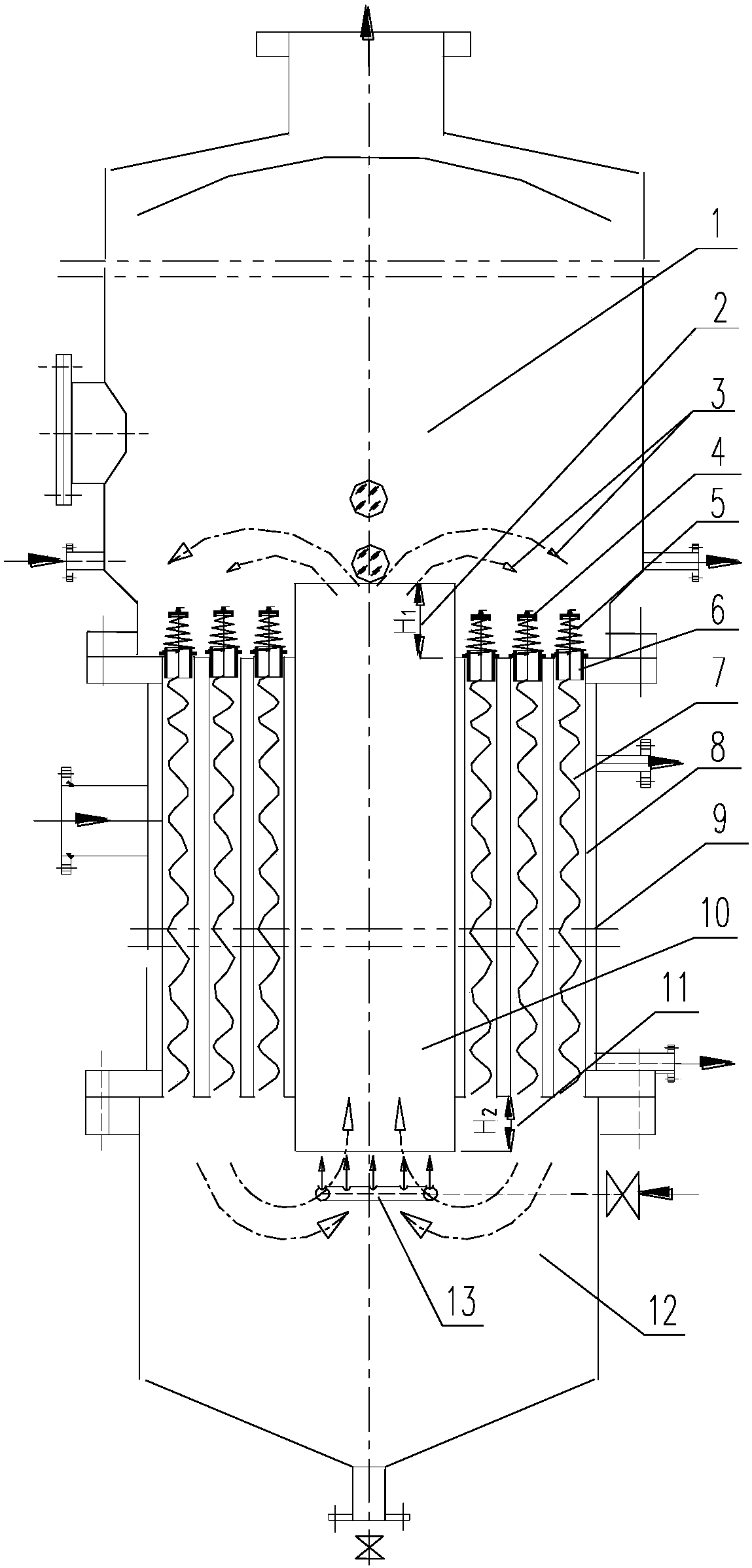

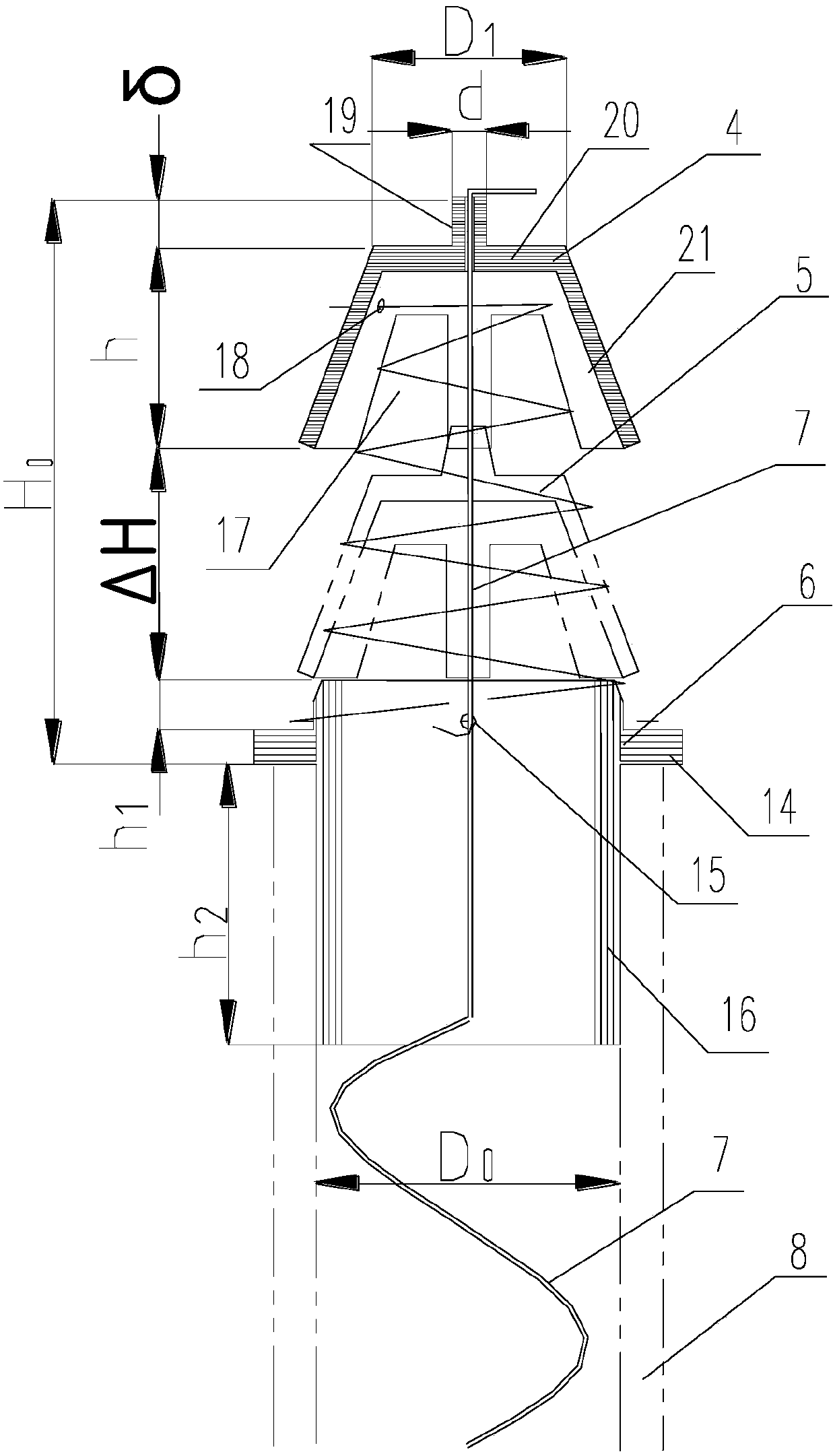

[0014] Attached below figure 1 , figure 2 , the present invention is described in further detail.

[0015] In the figure: 1. Evaporation chamber, 2. Extending weir, 3. Surfing flow, 4. Surfing head, 5. Conical compression spring, 6. Nozzle seat, 7. Cleaning screw, 8. Heating pipe, 9. Heating chamber , 10. Central circulation pipe, 11. Down extension section, 12. Bottom chamber, 13. Reverse circulation steam injection ring, 14. Flange, 15. Fixing hole, 16. Intubation tube, 17. Inlet window, 18. Assembly hole, 19, bearing stand, 20, surfing disc, 21, surfing skirt.

[0016] A surf cleaning type reverse natural circulation evaporator, the main components are evaporation chamber 1, central circulation pipe 10, heating chamber 9, bottom chamber 12, reverse circulation steam injection ring 13, heating pipe 8, surfing head 4, conical compression Spring 5, cleaning screw 7, orifice seat 6. The evaporation chamber 1, the central circulation pipe 10, the heating chamber 9, the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com